A method for regulating the krafft temperature of surfactant by adjusting ph method

A surfactant and aqueous solution technology, applied in chemical instruments and methods, transportation and packaging, organic chemistry, etc., can solve the problem of irreversible regulation of Krafft temperature, and achieve the effect of broadening the scope of use, easy promotion, and easy recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

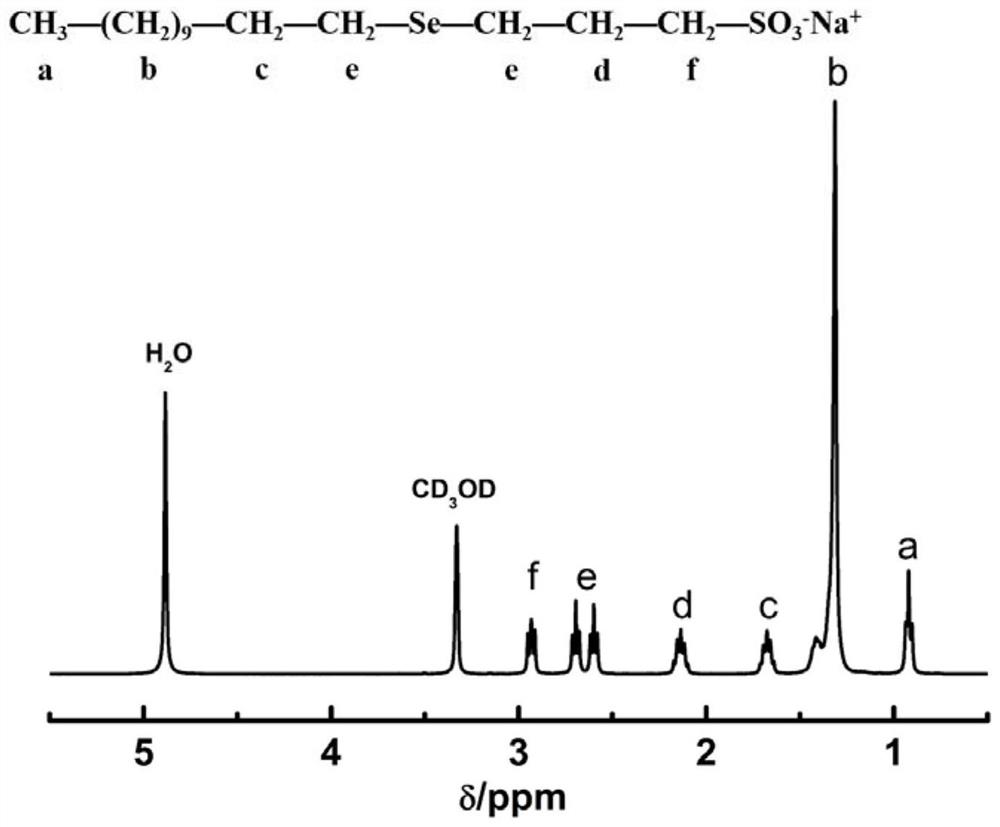

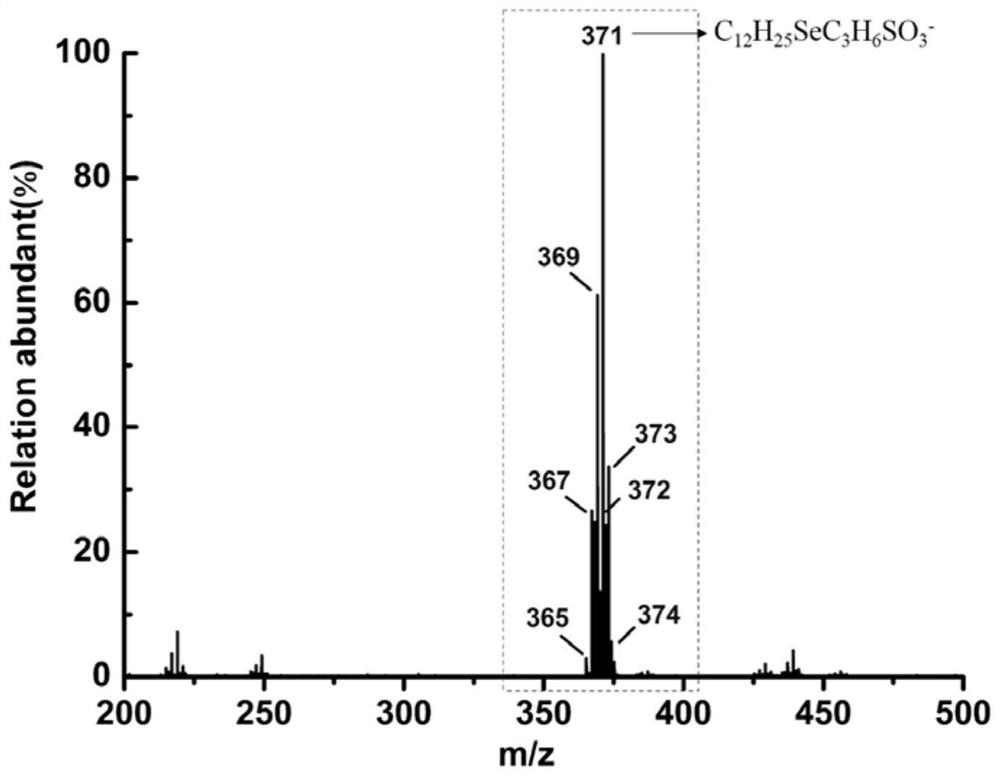

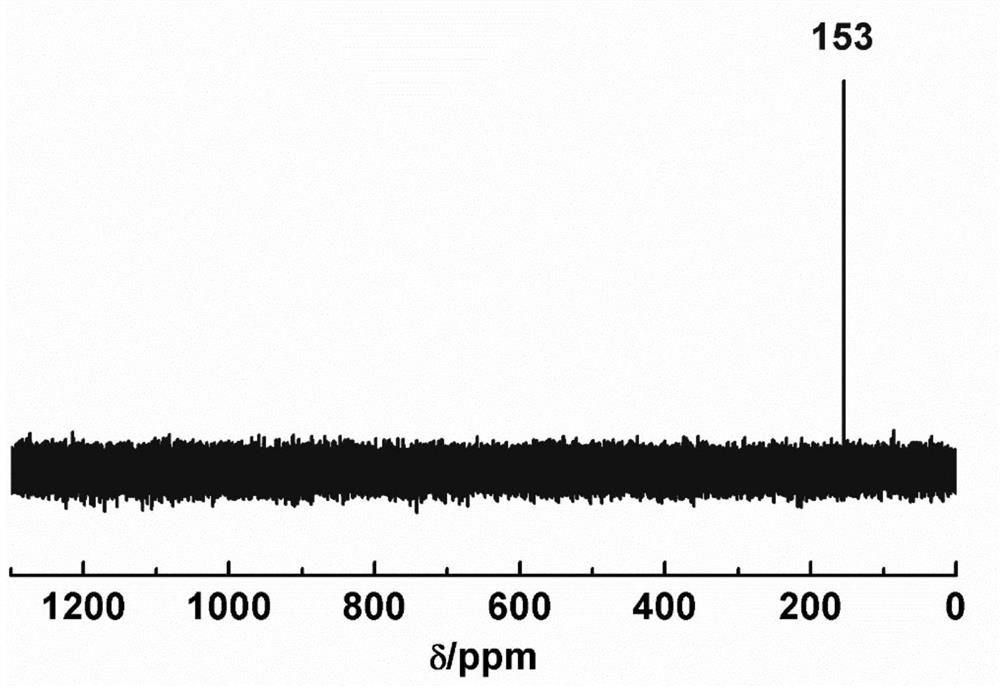

[0048] The preparation method of alkyl selenopropyl sulfonate, the steps are as follows:

[0049] (1) Synthesis of dodecyl diselenide: Weigh 10.0 g of selenium powder and place it in a 500 ml three-necked round-bottomed flask. Under nitrogen protection, add 75 ml of tetrahydrofuran and stir at room temperature for 10 minutes, then add 6.59 g of 75 ml The sodium hydroxide dispersed in tetrahydrofuran was placed in a 500 ml three-necked flask, stirred for 10 minutes, then 2.98 g (85% effective content) of hydrazine hydrate was weighed, dispersed with 50 ml tetrahydrofuran, and added to a 500 ml three-necked flask. After reacting for 30 minutes, 34.72 g of brominated alkanes were weighed, dispersed by adding 75 ml of tetrahydrofuran, and then transferred to a 500 ml three-neck flask. Reaction at room temperature for 8h, the crude product was obtained. The insoluble matter was removed by filtration, the solvent was evaporated to dryness, and then extracted with dichloromethane, a...

Embodiment 2

[0052] Embodiment 2 regulates the Krafft temperature of surfactant alkyl selenopropyl sulfonate

[0053] Taking 3-dodecylselenium-1-propanesulfonate sodium as an example, its Krafft temperature is regulated by adding acid-oxidation and reduction-adding alkali:

[0054] (1) Prepare 10.000 grams of 3-dodecylselenium-1-propane sodium sulfonate aqueous solution with a mass fraction of 1%, place it at 4°C for 24 hours, and then gradually increase the temperature by slowly raising the temperature Temperature, to make it completely dissolve, record the temperature at this time as the Krafft temperature, and its value is 43.4±0.4°C;

[0055] (2) Weigh 0.5 gram of sodium dodecylselenium-1-propanesulfonate, then add 0.565 gram of N,N-dimethylethanolamine, then add deionized water to a total mass of 50.000 grams, record The pH at this moment is 10.36, adopts the method in (1) to measure its Krafft temperature, and its value is 40.2 ± 0.4 ℃;

[0056] (3) Weigh 0.5 gram of sodium dodecyl...

Embodiment 3

[0062] Taking sodium 3-hexadecylselenium-1-propanesulfonate as an example, adjust its Krafft temperature.

[0063] (1) Prepare 10.000 grams of an aqueous solution of 3-hexadecylselenium-1-propanesulfonate sodium solution with a mass fraction of 1%, place it at 4°C for 24 hours, and then gradually increase the temperature by slowly raising the temperature Temperature, to make it completely dissolve, record the temperature at this time as the Krafft temperature, and its value is 60.1±0.4°C;

[0064] (2) Weigh 0.5 g of sodium 3-hexadecylselenium-1-propanesulfonate, then add 0.323 g of N,N,N,N-tetramethylethylenediamine, and then add deionized water to the total The mass is 50.000 grams, and the pH recorded at this time is 10.57. The Krafft temperature is measured by the method in (1), and its value is 55.3±0.4°C;

[0065] (3) Regulate its Krafft temperature by adding acid: weigh 0.5 gram of 3-hexadecylselenium-1-propanesulfonate sodium, then add 0.323 gram of N,N,N,N-tetramethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com