Process method of using micro reactor for continuously producing 2,2-dimethylolpropionic acid

A dimethylolpropionic acid, microreactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, carboxylate preparation, etc., can solve the complex production process, difficult post-processing, labor-intensive It can reduce the number of operators, the production process is safe and efficient, and the waste water discharge can be reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

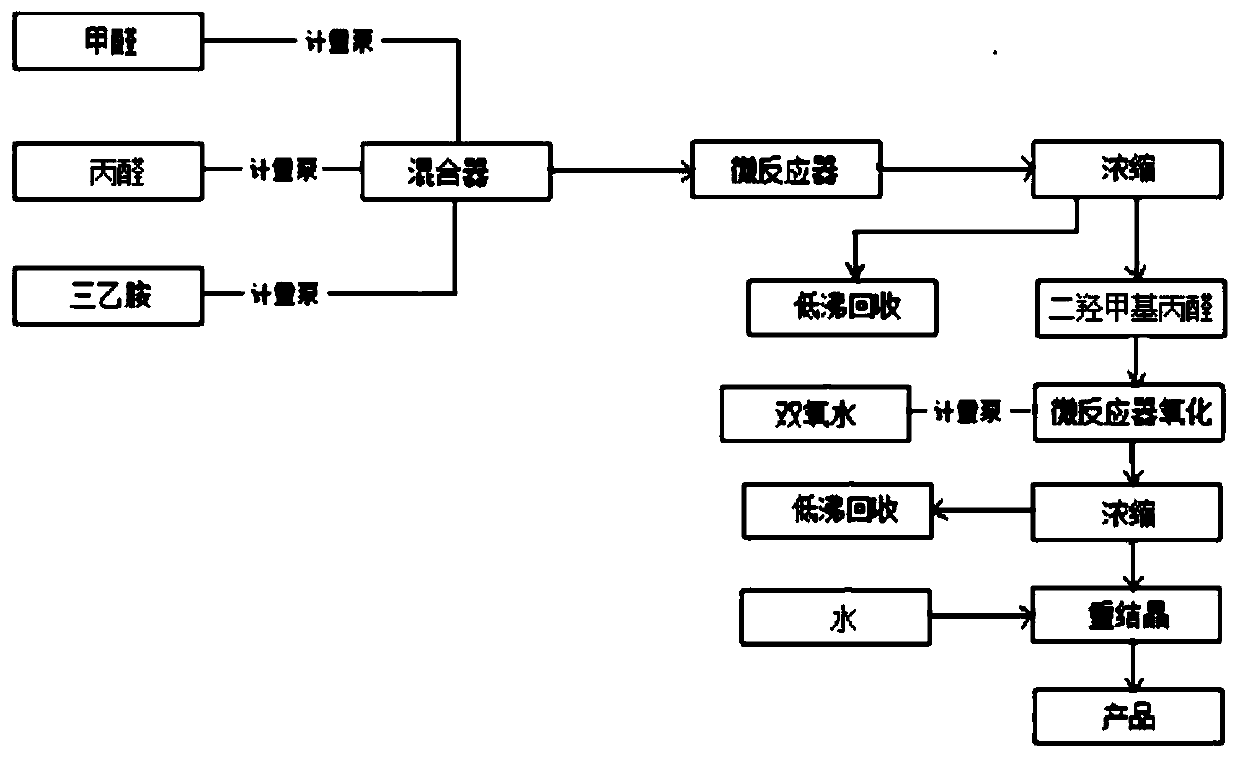

Method used

Image

Examples

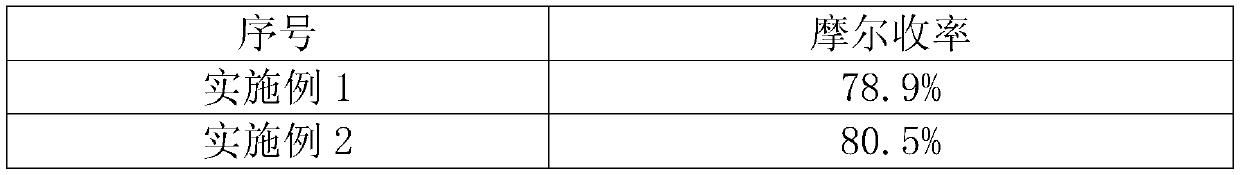

Embodiment 1

[0030] Embodiment 1, a kind of process that uses microreactor to continuously produce 2,2-dimethylolpropionic acid comprises the steps:

[0031] S1, formaldehyde, propionaldehyde and triethylamine metered and quantified by metering pumps are pumped into the mixer for forced mixing, the concentration of formaldehyde is 37%, the concentration of propanol is 99%, triethylamine, formaldehyde and propionaldehyde The flow rates are 250ml / min, 2000ml / min, and 777ml / min respectively, and the flow rates of triethylamine, formaldehyde and propionaldehyde are all 0.1m / s, the reaction temperature is 70°C, the pressure is 0.2MPa, and the reaction residence time is 100 seconds , triethylamine and hydrogen peroxide can be recovered by low boiling, and then enter the microreactor for condensation reaction to obtain a reaction solution mainly containing 2,2-dimethylolpropanal. The material of the mixer and the microreactor is glass Any one or more of stainless steel, resin and silicon carbide,...

Embodiment 2

[0035] Embodiment 2, a kind of processing method that uses microreactor to continuously produce 2,2-dimethylol propionic acid, comprises the steps:

[0036] S1. Formaldehyde, propionaldehyde and triethylamine are pumped into the mixer for forced mixing with a metering pump. The concentration of formaldehyde is 37%, and the concentration of propanol is 99%. Triethylamine, formaldehyde and propionaldehyde The flow rates are 250ml / min, 2000ml / min, and 777ml / min respectively, and the flow rates of triethylamine, formaldehyde and propionaldehyde are all 0.3m / s, the reaction temperature is 90°C, the pressure is 0.4MPa, and the reaction residence time is 120 seconds , triethylamine and hydrogen peroxide can be recovered by low boiling, and then enter the microreactor for condensation reaction to obtain a reaction solution mainly containing 2,2-dimethylolpropanal. The material of the mixer and the microreactor is glass Any one or more of stainless steel, resin and silicon carbide, a h...

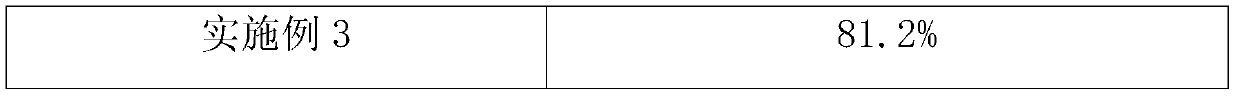

Embodiment 3

[0040] Embodiment 3, a kind of process method that uses microreactor to continuously produce 2,2-dimethylol propionic acid, comprises the steps:

[0041]S1. Formaldehyde, propionaldehyde and triethylamine are pumped into the mixer for forced mixing with a metering pump. The concentration of formaldehyde is 37%, and the concentration of propanol is 99%. Triethylamine, formaldehyde and propionaldehyde The flow rates are 250ml / min, 2000ml / min, and 777ml / min respectively, and the flow rates of triethylamine, formaldehyde and propionaldehyde are all 0.5m / s, the reaction temperature is 110°C, the pressure is 0.6MPa, and the reaction residence time is 150 seconds , triethylamine and hydrogen peroxide can be recovered by low boiling, and then enter the microreactor for condensation reaction to obtain a reaction solution mainly containing 2,2-dimethylolpropanal. The material of the mixer and the microreactor is glass Any one or more of stainless steel, resin and silicon carbide, a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com