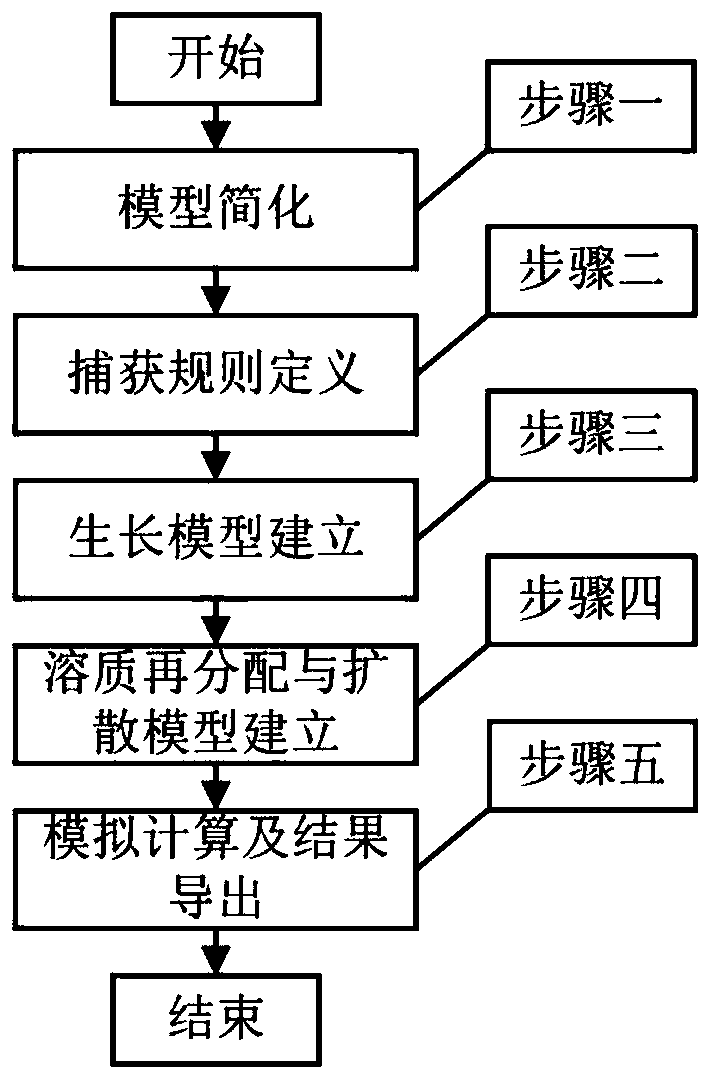

Method for simulating single dendritic crystal growth numerical value in ternary alloy solidification process

A ternary alloy, numerical simulation technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of lack of ternary alloy solidification structure CA model and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

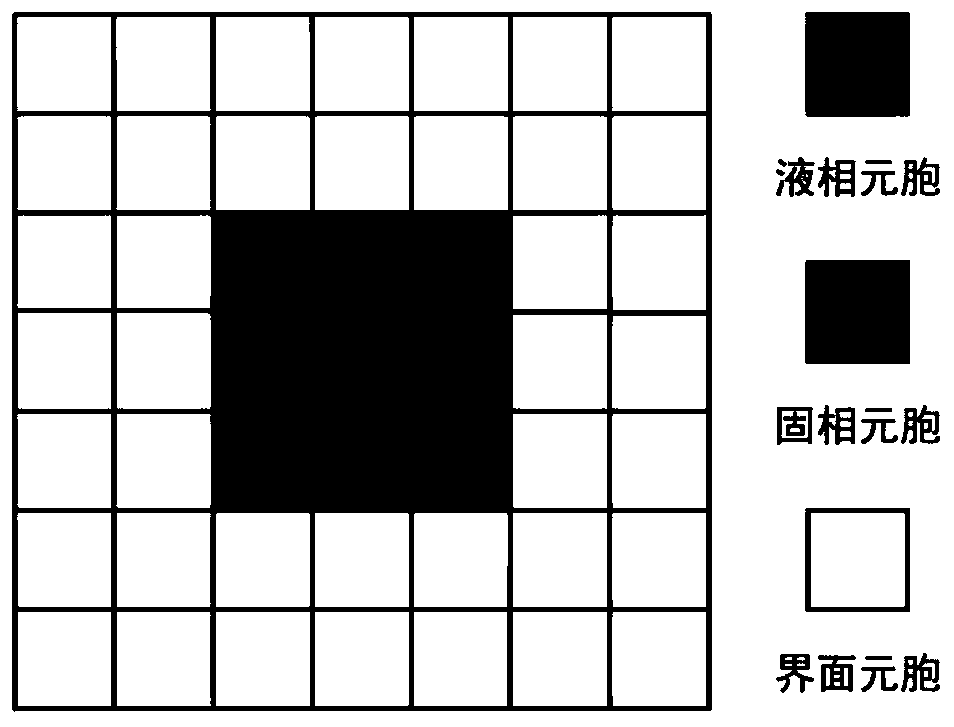

Method used

Image

Examples

Embodiment 1

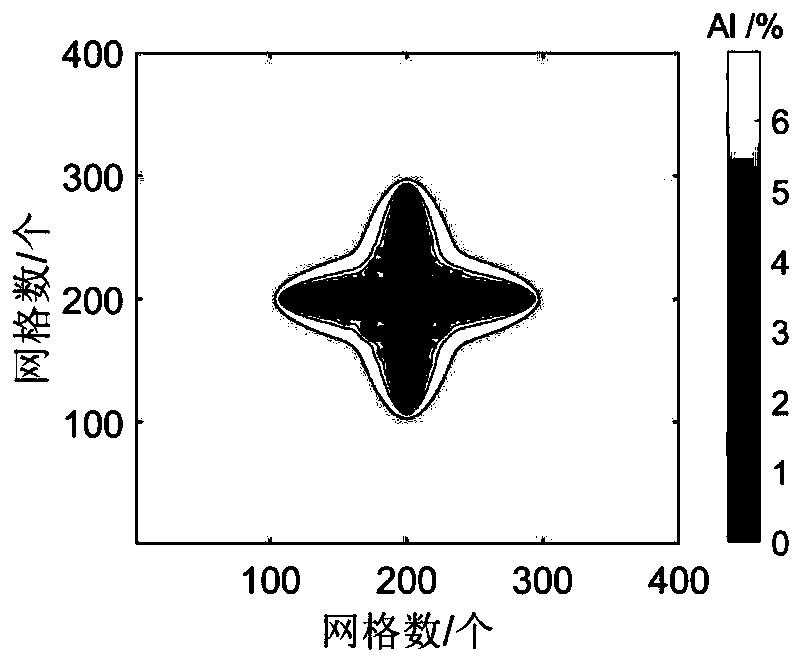

[0105] Taking Ti-6Al-4V ternary alloy as an example, the method of the present invention is simulated, and the used alloy thermophysical parameters are as shown in table 1 during simulation:

[0106] Table 1

[0107]

[0108] Table 1 shows the thermal physical parameters used in the calculation of Ti-6Al-4V alloy simulation.

[0109] Simulation results such as image 3 , Figure 4 , Figure 5 , Image 6 It can be seen from the figure that when the preferred growth direction is 0°, the secondary dendrites on the primary dendrite arms are underdeveloped, and there are only a small number of fine secondary dendrites, while when the preferred growth direction is 30°, the primary dendrites are not developed. Coarse secondary dendrites grow on the dendrite arms. And the diffusion layer of Al element on the interface is larger than the diffusion layer of V element on the interface.

Embodiment 2

[0111] Taking Fe-0.8%C-0.3%Si ternary alloy as an example, the method of the present invention is simulated, and the used alloy thermophysical parameters during simulation are as shown in table 2:

[0112] Table 2

[0113]

[0114] Table 2 shows the thermal physical parameters used in the calculation of Fe-0.8%C-0.3%Si alloy simulation.

[0115] Simulation results such as Figure 7 , Figure 8 , Figure 9 , Figure 10 It can be seen from the figure that when the anisotropy is 0, the equiaxed crystal starts from the original grain, and the primary dendrites grow uniformly around, and there are many secondary dendrites on the dendrite arms, and the overall dendrites The crystal morphology is snowflake-like. When the anisotropy is 0.2, the primary dendrites do not grow scattered around, but grow according to the crystal structure, and well-developed secondary and tertiary dendrites can be observed on the primary dendrite arms.

Embodiment 3

[0117] Taking Fe-0.6%C-0.4%Si ternary alloy as an example, the method of the present invention is simulated, and the thermal physical parameters of the alloy used during simulation are as shown in Table 3:

[0118] table 3

[0119]

[0120] Table 3 shows the thermophysical parameters used in the calculation of the Fe–0.6%C–0.4%Si alloy simulation.

[0121] Simulation results such as Figure 11 , Figure 12 , Figure 13 , Figure 14 It can be seen from the figure that when the degree of subcooling is 5K, the primary dendrite arm is short, and the number of secondary dendrites on the primary dendrite arm is small, and the secondary dendrite is underdeveloped. When the subcooling degree is 8K, the primary dendrites increase obviously, and there are well-developed secondary dendrites on the primary dendrite arms.

[0122] It can be seen from the above three examples that the present invention can successfully simulate the growth morphology, solute distribution state, cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com