Fuel cell bipolar plate and fuel cell voltage routing inspection insertion part

A fuel cell and bipolar plate technology, which is applied to fuel cell parts, fuel cells, electrical components, etc., can solve the problems of difficult connection, difficult manufacturing, and insufficient clamping force, so as to improve the anti-vibration ability and reduce the Assembly difficulty and the effect of reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

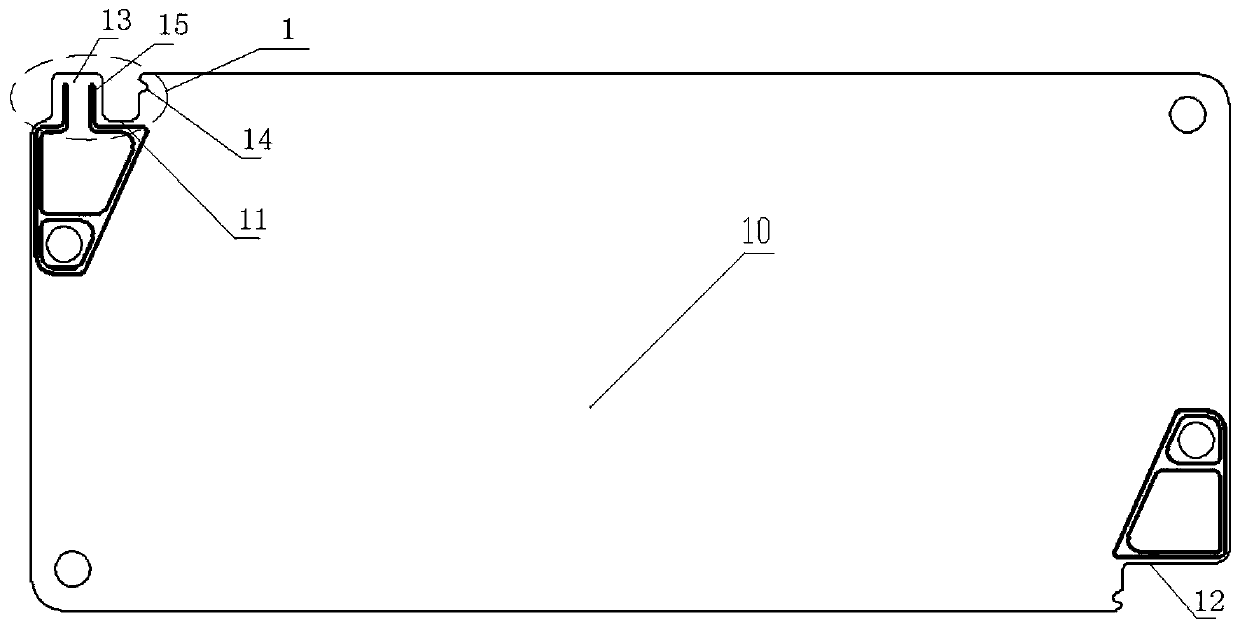

[0048] This embodiment provides a fuel cell bipolar plate 10, including an inspection plug-in connection structure 1 for connecting the inspection plug-in for voltage detection. The inspection plug-in connection structure 1 includes: The direction of the anti-disengagement buckle 14 formed by protruding or recessing and the edge of the bipolar plate 10 protrude outward along a direction parallel to the insertion direction of the inspection plug to form a contact terminal 13 .

[0049] Further, in the above technical solution, the anti-off buckle 14 is arranged on the edge of the bipolar plate 10 .

[0050] This embodiment also provides a fuel cell voltage inspection plug-in 2, which is used to insert the above-mentioned inspection plug-in connection structure 1 for voltage detection. The inspection plug-in 2 includes a compression terminal 21 and a 21 an outer insulator 23;

[0051] The inspection plug-in 2 clamps the contact terminal 13 through the pressing terminal 21;

[...

Embodiment 2

[0058] Such as figure 1 As shown, this embodiment provides a fuel cell bipolar plate 10. The difference between this embodiment and Embodiment 1 is that the inspection plug-in connection structure 1 includes:

[0059] At least one first notch 11 provided along the edge of the bipolar plate 10; on the edge of the first notch 1, a contact terminal 13 protrudes outward in a direction parallel to the insertion direction of the inspection plug-in, and a contact terminal 13 is formed along a direction not parallel to the The direction of the insertion direction of the inspection plug-in protrudes or sags to form an anti-off buckle 14;

[0060] Specifically, the anti-off buckle 14 is on the same plane as the bipolar plate 10, and the extension line of the protruding or concave direction of the anti-off buckle 14 intersects the extension line of the insertion direction of the inspection plug-in;

[0061] The contact terminal 13 and the anti-off buckle 14 work together to make the ins...

Embodiment 3

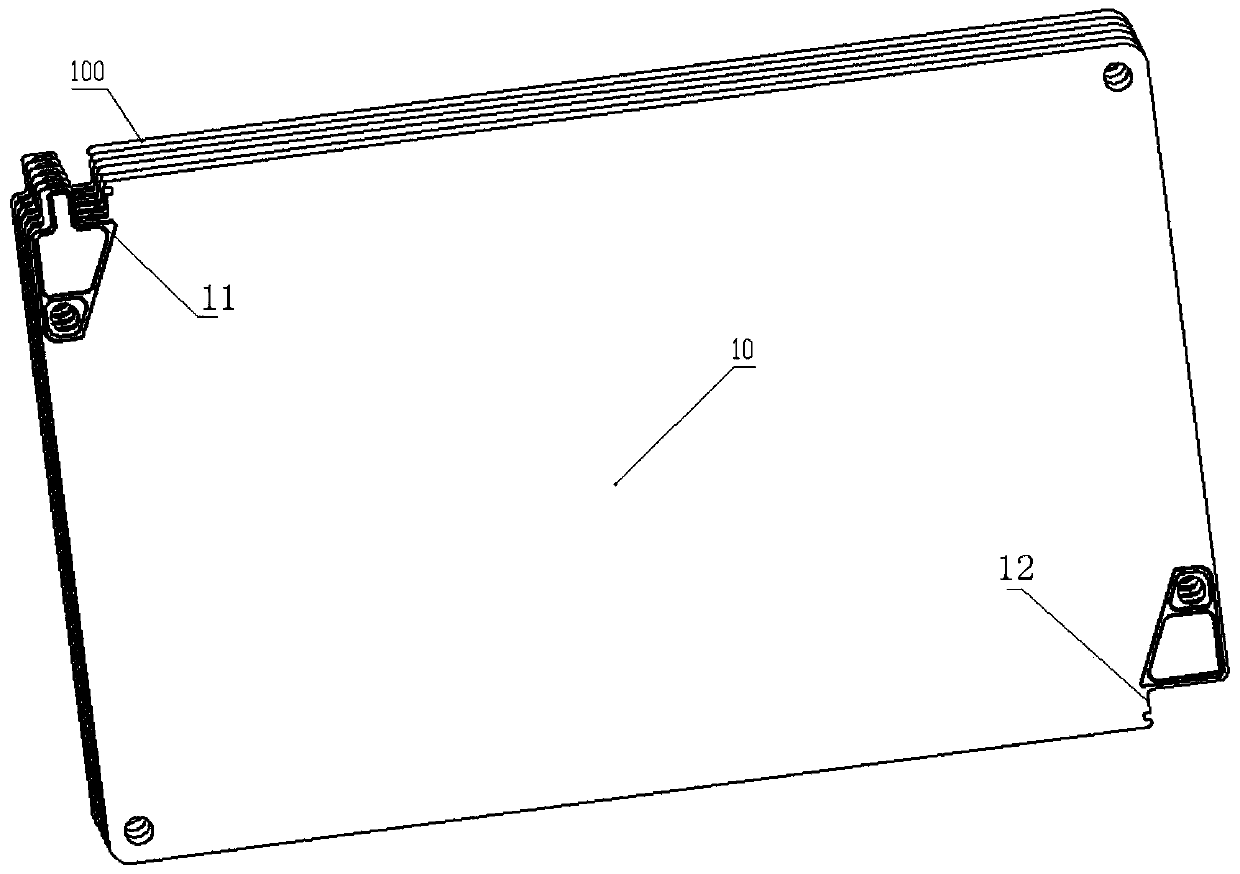

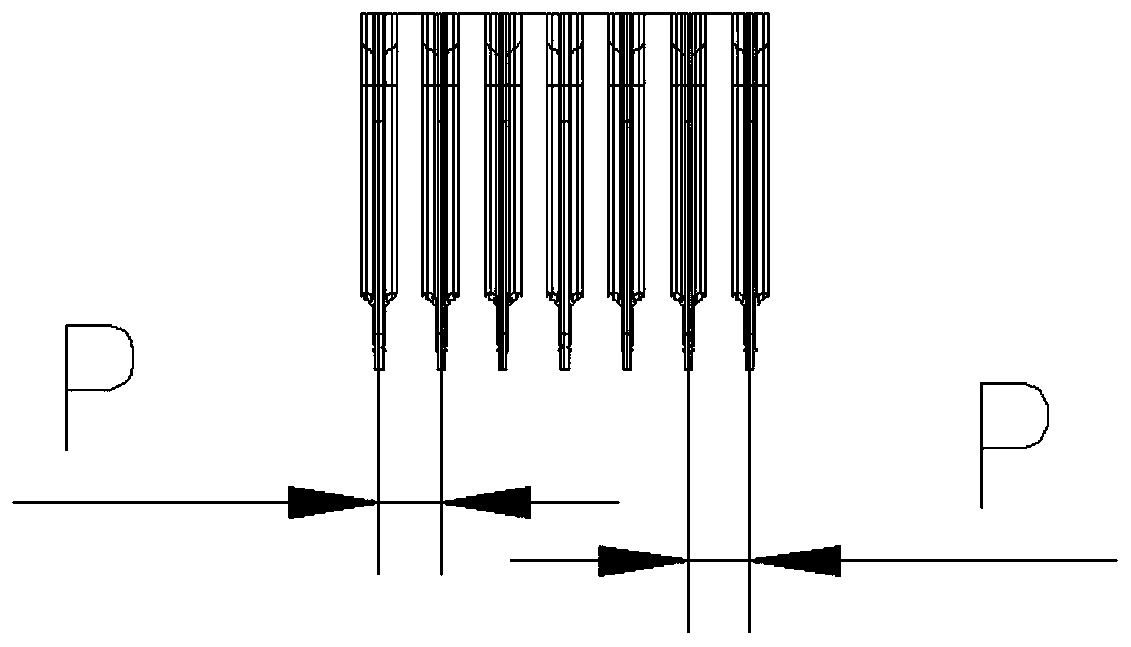

[0088] Such as Figure 11-12 As shown, on the basis of Embodiment 2, the only difference between this embodiment and Embodiment 2 is that the bipolar plate 10 includes two first notches 11 and two second notches 12, and this embodiment The bipolar plate provided in the example can realize that the distance between adjacent contact terminals is 2P, and conduct voltage detection for each battery; specifically, the two first notches 11 are located on the same side of the bipolar plate 10, The two second notches 12 are located on the other side of the bipolar plate 10;

[0089] The number of inspection plug-ins in embodiment 2 is twice the number of inspection plug-ins in embodiment 1;

[0090] In this embodiment, the stacking method of the core assembly II 200 is adopted, and one of the contact terminals 13 is respectively selected on both sides of the core assembly II 200 to be inserted into the inspection plug-in 2, so that every two batteries of the stack can be aligned. vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com