Photocatalyst for efficiently degrading organic pollutants and preparation method of the photocatalyst

A technology of organic pollutants and photocatalysts, applied in the direction of physical/chemical process catalysts, water pollutants, chemical instruments and methods, etc., can solve the problems of catalysts being difficult to hydrate and disperse, so as to overcome easy hydration and disperse, and save treatment costs , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

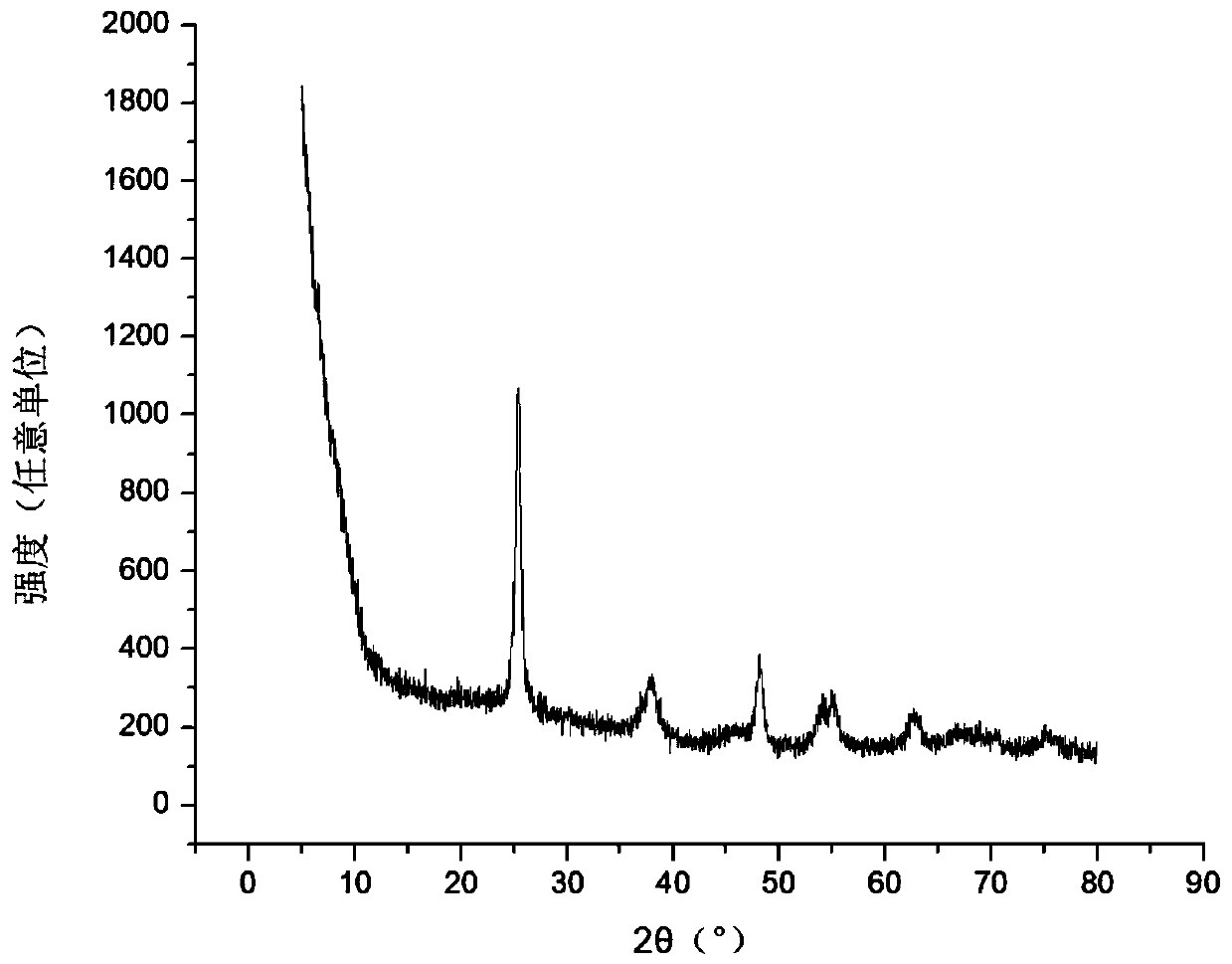

Image

Examples

Embodiment 1

[0048] Weigh 1.322 g of sodium silicate solid with a modulus of 3.2 and pour it into a beaker, add 10 ml of deionized water, and stir well until the solid is completely dissolved.

[0049] Weigh 3.9 g of concentrated sulfuric acid with a mass fraction of 98% and add it into 15.21 g of deionized water to dilute to a dilute sulfuric acid solution with a mass fraction of 20%.

[0050] Weigh FeSO 4 ·7H 2 Pour 0.418 g of O solid into a beaker, add 15 ml of deionized water, stir well until the solid is completely dissolved, and add dropwise dilute sulfuric acid solution to adjust the pH to 5.

[0051] Slowly add dilute sulfuric acid into the sodium silicate solution dropwise, and stop adding dilute sulfuric acid when the pH of the sol is adjusted to 5, add a mixture of 2.146g of metatitanic acid and 1.486g of aluminum oxide that has been well ground into the silica sol, and disperse it by ultrasonic 30min to disperse the mixture evenly.

[0052] Put the mixed material into a cons...

Embodiment 2

[0057] Weigh 1.322 g of sodium silicate solid with a modulus of 3.2 and pour it into a beaker, add 10 ml of deionized water, and stir well until the solid is completely dissolved.

[0058] Weigh 3.9 g of concentrated sulfuric acid with a mass fraction of 98% and add it into 15.21 g of deionized water to dilute to a dilute sulfuric acid solution with a mass fraction of 20%.

[0059] Weigh FeSO 4 ·7H 2 Pour 0.696 g of O solid into a beaker, add 15 ml of deionized water, stir well until the solid is completely dissolved, and add dropwise dilute sulfuric acid solution to adjust the pH to 5.

[0060] Slowly add dilute sulfuric acid into the sodium silicate solution dropwise, and stop the dropwise addition of dilute sulfuric acid when the pH of the sol is adjusted to 5, add a mixture of 2.233g of metatitanic acid and 1.486g of aluminum oxide that has been well ground into the silica sol, and disperse it by ultrasonic 30min to disperse the mixture evenly.

[0061] Put the mixed ma...

Embodiment 3

[0066] Weigh 1.322 g of sodium silicate solid with a modulus of 3.2 and pour it into a beaker, add 10 ml of deionized water, and stir well until the solid is completely dissolved.

[0067] Weigh 3.9 g of concentrated sulfuric acid with a mass fraction of 98% and add it into 15.21 g of deionized water to dilute to a dilute sulfuric acid solution with a mass fraction of 20%.

[0068] Weigh FeSO 4 ·7H 2 Pour 1.01 g of O solid into a beaker, add 15 ml of deionized water, stir well until the solid is completely dissolved, add dropwise dilute sulfuric acid solution to adjust the pH to 5.

[0069] Slowly add dilute sulfuric acid into the sodium silicate solution dropwise, and stop adding dilute sulfuric acid when the pH of the sol is adjusted to 5, add a mixture of 2.320g metatitanic acid and 1.486g aluminum oxide that has been well ground into the silica sol, and disperse it by ultrasonic 30min to disperse the mixture evenly.

[0070] Put the mixed material into a constant temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com