Automated forming method for high-speed rail composite material body

A composite material and molding method technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of weak lateral bonding ability of pultruded profiles, and can solve the problem of weak lateral bonding ability, ensure reliability, and reduce connecting parts. effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0026] Such as Figure 1-7 Shown: a high-speed rail composite body automatic forming method, including the following steps

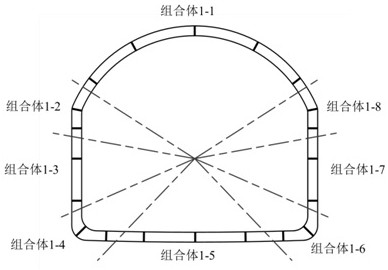

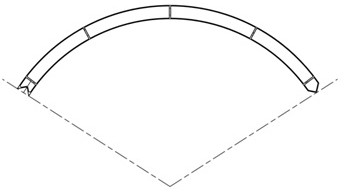

[0027] (1) The high-speed rail body can be regarded as a cylindrical overall load-bearing structure, firstly, as figure 1 As shown, the cylindrical section of the vehicle body is partitioned, and combinations 1-1, 1-2, 1-3, 1-4, 1-5, 1-6, 1-7, 1-8 are respectively provided; Divided into multi-cavity carbon fiber composite structures with different cross-sectional shapes;

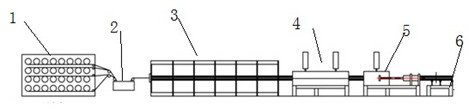

[0028] (2) Based on the zoning results of step 1, pultrusion equipment is used to pultrude multi-cavity carbon fiber composite materials for high-speed rail; the multi-cavity carbon fiber composite material structure pultrusion equipment includes creel 1, yarn guide 2, Resin glue tank 3, thermoforming mold 4, traction device 5 and cutting device 6;: T300-3K carbon fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com