Photocrosslinking double-modified silk fibroin-gelatin composite bio-ink as well as preparation method and application thereof

A silk fibroin, bio-ink technology, applied in the directions of additive manufacturing, manufacturing tools, metal processing equipment, etc., can solve the problems of brittle large gel structure and other problems, achieve a high degree of automation, good compression resistance and elasticity, enhanced The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

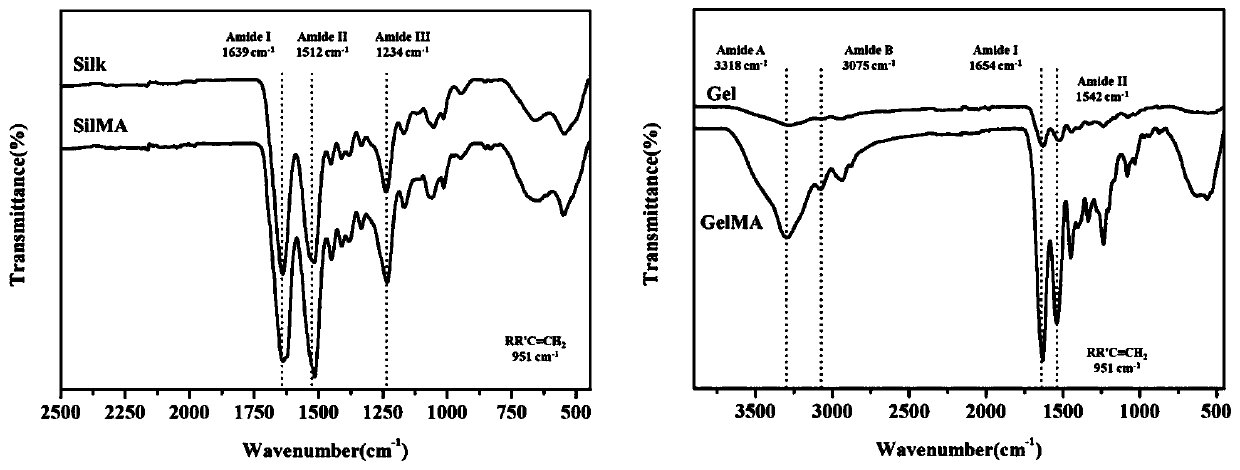

[0036] (1) After dissolving the boiled silk fibroin fibers with LiBr, 424mM GMA solution was added to the mixture solution, and reacted at 60° C. for 3 hours at a speed of 300 rpm to produce a high-yield reaction. After filtering, use a dialysis bag with a molecular weight of 12-14kDa to dialyze for 4 days, replace the deionized water every 4h, then place it in a -80°C refrigerator overnight, and obtain methacrylylated silk fibroin (SilMA) after freeze-drying. Store at -4°C for use;

[0037] (2) Dissolve 10 g of gelatin in 100 mL of deionized water, let stand at room temperature for 1 h, and then stir in a constant temperature water bath at 60°C until completely dissolved. Under light-shielded conditions, 5 mL of methacrylic anhydride was added dropwise to the gelatin solution at a rate of 1 mL / min at 60° C., and the stirring speed was 300 rpm. After mixing evenly, shake and react in a constant temperature shaker at 50° C. for 3 h, and then add 400 mL of deionized water at 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com