Degradable self-repairing water-retaining sand-fixing agent and preparation method thereof

A sand-fixing agent and self-repairing technology, applied in chemical instruments and methods, other chemical processes, organic fertilizers, etc., can solve the problems of pollution in desert areas and the refractory degradation of chemical sand-fixing agents, and achieve long-term sand-fixing time, good sand-fixing effect, The effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

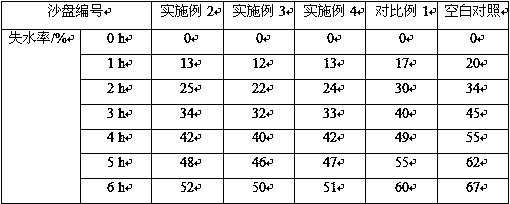

Embodiment 1

[0022] Step 1. Preparation of hydrogel: mix 10 parts by weight of acrylamide, 3 parts of xanthan gum, 10 parts of acrylic acid, and 100 parts of water, add 0.5% of the mass of the mixture as initiator potassium persulfate, and add 0.3% of the mass of the mixture Combined agent N,N'-methylenebisacrylamide, stirred for 20 minutes to obtain a hydrogel for use;

[0023] Step 2. Preparation of microcapsules: mix water-based polyurethane powder with stearic acid in a mass ratio of 100:5, and process it through a vortex airflow refiner at a speed of 300 rpm, so that stearic acid can fully wrap the water-based polyurethane powder, and then add a mass concentration of 8 % of gelatinized starch liquid, the mass ratio of refined modified water-based polyurethane powder to gelatinized starch liquid is 3:2; spray dry at 100°C to obtain microcapsules for use;

[0024] Step 3. Preparation of degradable self-repairing water-retaining and sand-fixing agent: 30 parts by weight of hydrogel in st...

Embodiment 2

[0026] Step 1. Preparation of hydrogel: Mix 15 parts by weight of acrylamide, 5 parts of xanthan gum, 8 parts of acrylic acid, and 110 parts of water, add 0.5% of the mass of the mixture as an initiator potassium persulfate, and add 0.3% of the mass of the mixture Combined agent N,N'-methylenebisacrylamide, stirred for at least 10 minutes, and obtained hydrogel for use;

[0027] Step 2. Preparation of microcapsules: mix water-based polyurethane powder with stearic acid in a mass ratio of 100:5, and process it through a vortex airflow refiner at a speed of 300 rpm, so that stearic acid can fully wrap the water-based polyurethane powder, and then add a mass concentration of 8 % of gelatinized starch liquid, the mass ratio of refined modified water-based polyurethane powder to gelatinized starch liquid is 3:2; spray dry at 100°C to obtain microcapsules for use;

[0028] Step 3. Preparation of degradable self-repairing water-retaining and sand-fixing agent: 30 parts by weight of h...

Embodiment 3

[0030] Step 1. Preparation of hydrogel: Mix 15 parts by weight of acrylamide, 5 parts of xanthan gum, 10 parts of acrylic acid, and 150 parts of water, add 0.5% of the mixture mass of potassium persulfate initiator, and add 0.3% of the mass of the mixture Combined agent N,N'-methylenebisacrylamide, stirred for at least 10 minutes, and obtained hydrogel for use;

[0031] Step 2, preparation of microcapsules: water-based polyurethane powder and stearic acid mass ratio of 100:5 are mixed, and the rotational speed of the vortex airflow refiner is 500rpm to make stearic acid fully wrap the water-based polyurethane powder, and then add a mass concentration of 8 % of gelatinized starch liquid, the mass ratio of refined modified water-based polyurethane powder to gelatinized starch liquid is 3:2; spray dry at 100°C to obtain microcapsules for use;

[0032] Step 3. Preparation of degradable self-repairing water-retaining and sand-fixing agent: 25 parts by weight of hydrogel in step 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com