Bioactive composite antibacterial soap and preparation method thereof

A technology of biologically active and antibacterial soap, which is applied in the field of daily chemical cleaning products, can solve the problems of complex formula and increased cost of antibacterial soap preparation, and achieve the effect of broad antibacterial spectrum, no unpleasant smell, and high antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A biologically active compound antibacterial soap, comprising the following components in mass percentage: 89% plant soap base, 10% sophorolipid aqueous solution and 1% lysozyme aqueous solution; the concentration of the sophorolipid aqueous solution is 950g / L , the concentration of lysozyme aqueous solution is 120g / L.

[0031] Preparation steps:

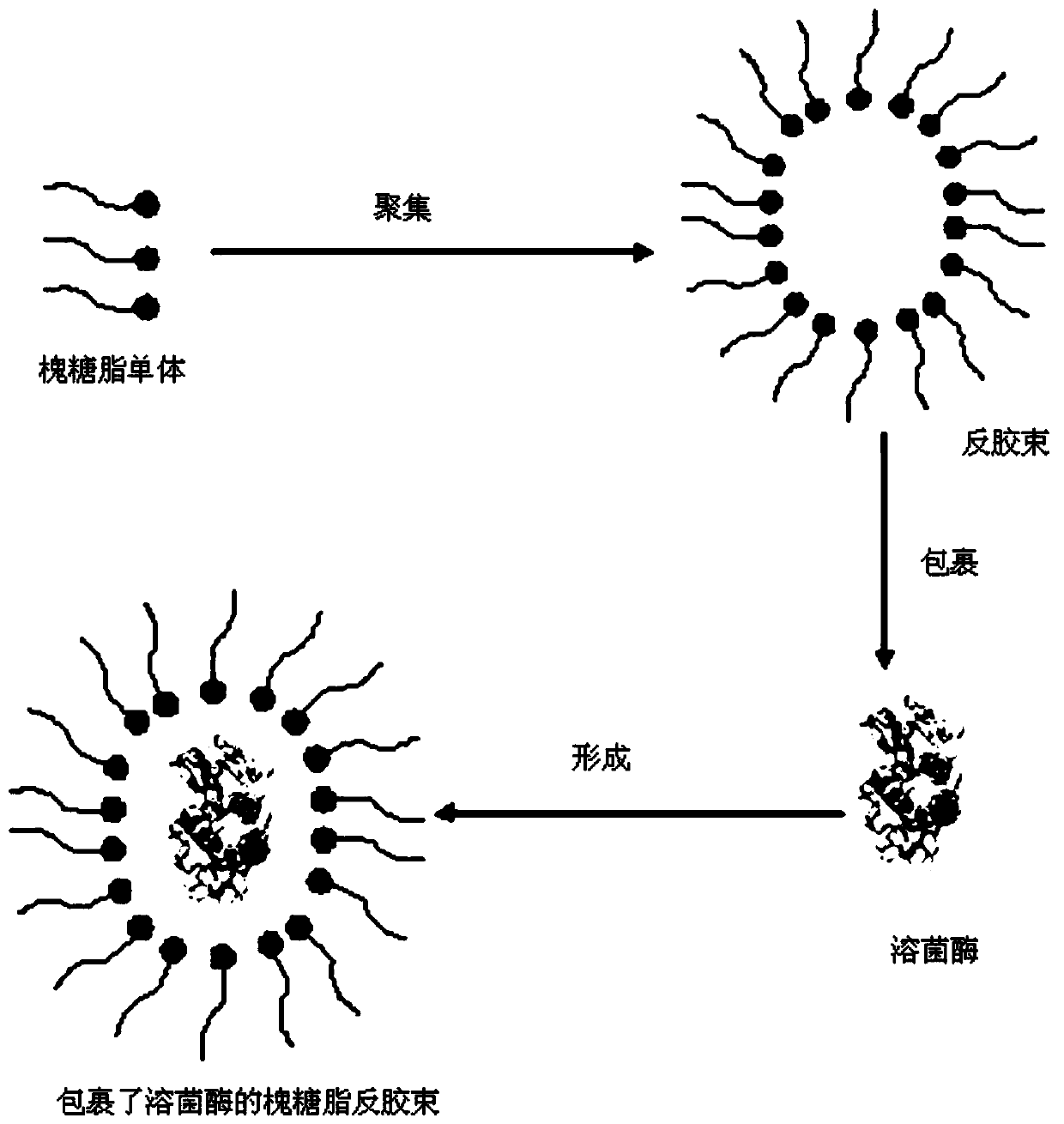

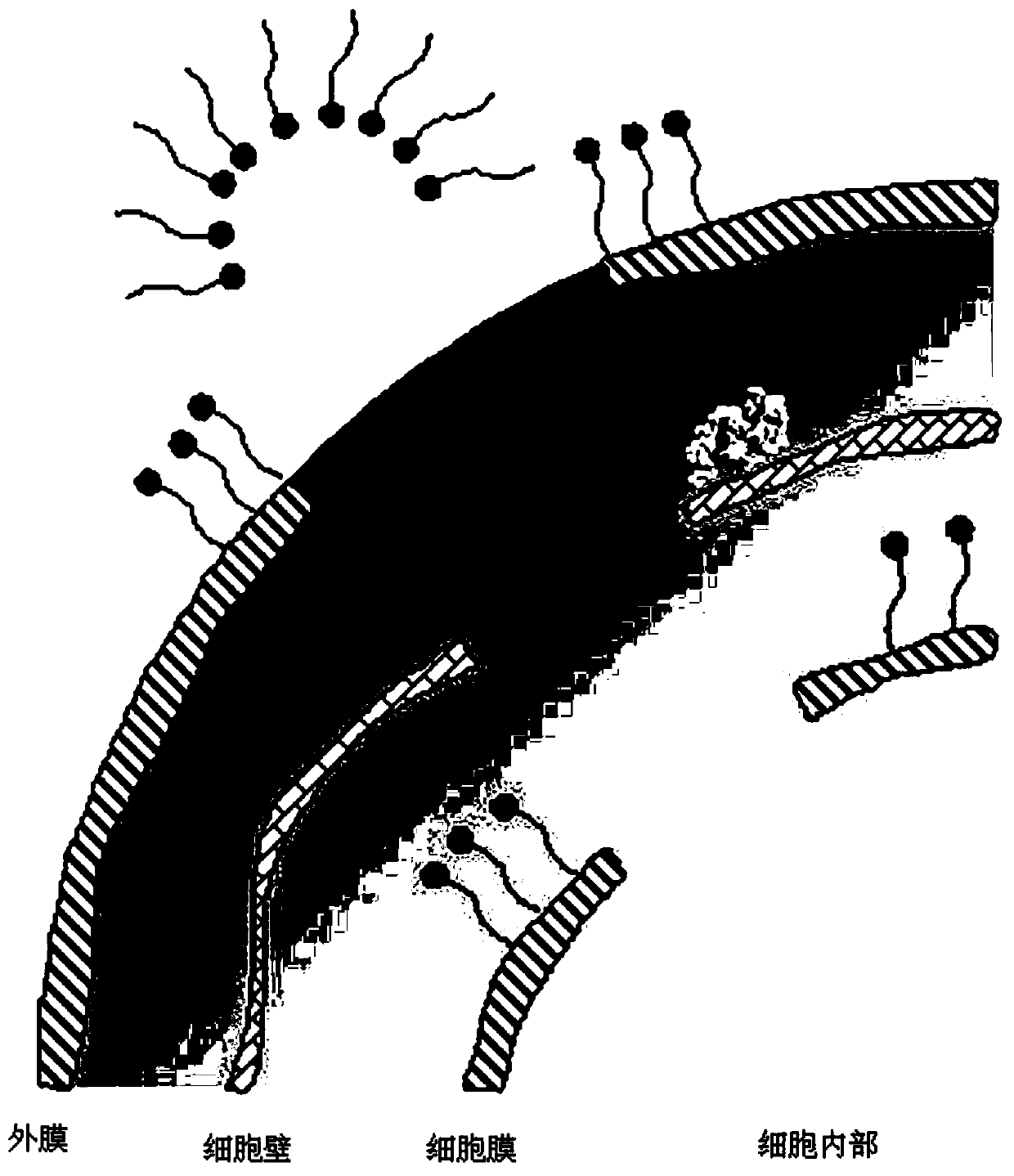

[0032] S1: Weigh the formulated amount of sophorolipid aqueous solution and lysozyme aqueous solution respectively, mix the two, stir slowly at 25-30°C, 30 rpm for 30 minutes, and mix evenly to obtain a mixture of sophorolipid reverse micelles-coated lysozyme;

[0033] S2: Weigh the plant soap base of the formula amount, dissolve it completely at 45-55°C, then add the mixture of sophorolipid reverse micelles wrapped with lysozyme, stir at 100rpm for 10min, and mix evenly to obtain a mixture;

[0034] S3: Pour the mixture into a mold, solidify and form at 15-30° C. to obtain a biologically active compound antibacterial soap. ...

Embodiment 2

[0036] A biologically active compound antibacterial soap, comprising the following components in mass percentage: 97.8% plant soap base, 2% sophorolipid aqueous solution and 0.2% lysozyme aqueous solution; the concentration of the sophorolipid aqueous solution is 850g / L , the concentration of lysozyme aqueous solution is 110g / L.

[0037] Preparation steps:

[0038] S1: Weigh the formulated amount of sophorolipid aqueous solution and lysozyme aqueous solution respectively, mix the two, stir slowly at 25-30°C and 25 rpm for 25 minutes, and mix evenly to obtain a mixture of sophorolipid reverse micelles-coated lysozyme;

[0039] S2: Weigh the plant soap base of the formula amount, dissolve it completely at 45-55°C, then add the mixture of sophorolipid reverse micelles wrapped with lysozyme, stir at 90rpm for 15min, and mix evenly to obtain a mixture;

[0040] S3: Pour the mixture into a mold, solidify and form at 15-30° C. to obtain a biologically active compound antibacterial soa...

Embodiment 3

[0042] A biologically active compound antibacterial soap, comprising the following components in mass percentage: 94.5% plant soap base, 5% sophorolipid aqueous solution and 0.5% lysozyme aqueous solution; the concentration of the sophorolipid aqueous solution is 750g / L , the concentration of lysozyme aqueous solution is 100g / L.

[0043] Refer to Example 1 for the preparation steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com