Ground pipeline corrosion prevention device for oil field and operating method

An anti-corrosion device and oil pipe technology, which can be used in pipeline anti-corrosion/anti-rust protection, pipeline protection, pipes, etc., and can solve problems such as limited anti-corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

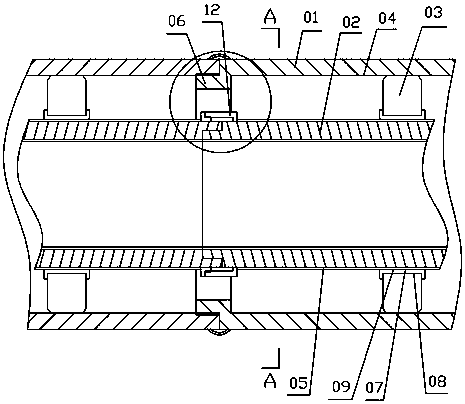

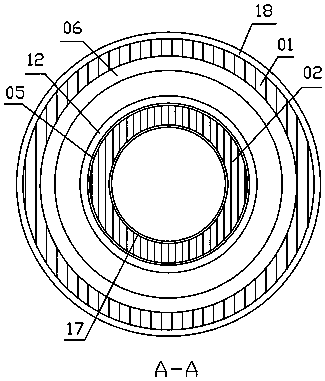

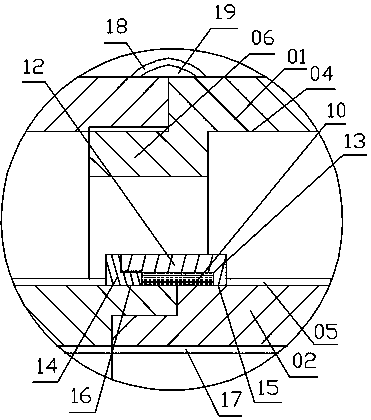

[0014] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0015] An anti-corrosion device for surface pipelines in oil fields, including anti-corrosion outer pipe 01, oil pipe 02, support ring 03, polyamide epoxy resin layer 05, rubber ring 07, 3PE heat shrinkable material 10, casing 12, locking disc 14, High-density polyethylene layer 17, epoxy coal tar pitch 19, the oil pipe 02 is placed inside the anti-corrosion outer pipe 01, the anti-corrosion outer pipe 01 has an outer pipe inner hole 04, and one end of the anti-corrosion outer pipe 01 has a connecting ring 06, and two adjacent The anti-corrosion outer pipe 01 is connected, the connecting ring 06 is adapted to the inner hole 04 of the outer pipe, the connecting ring 06 is connected to the inner hole 04 of the outer pipe through threads, the two adjacent oil pipes 02 are connected, and the outer side of the support ring 03 is adapted to the inner hole 04 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com