Wide-band oxygen sensor structure

An oxygen sensor, a wide-area technology, applied in the field of oxygen sensors, can solve the problems of shortening the service life of oxygen sensors, loose connection points, unwritten sensor elements and signal lines, etc., to improve assembly and debugging efficiency, avoid looseness, and avoid The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

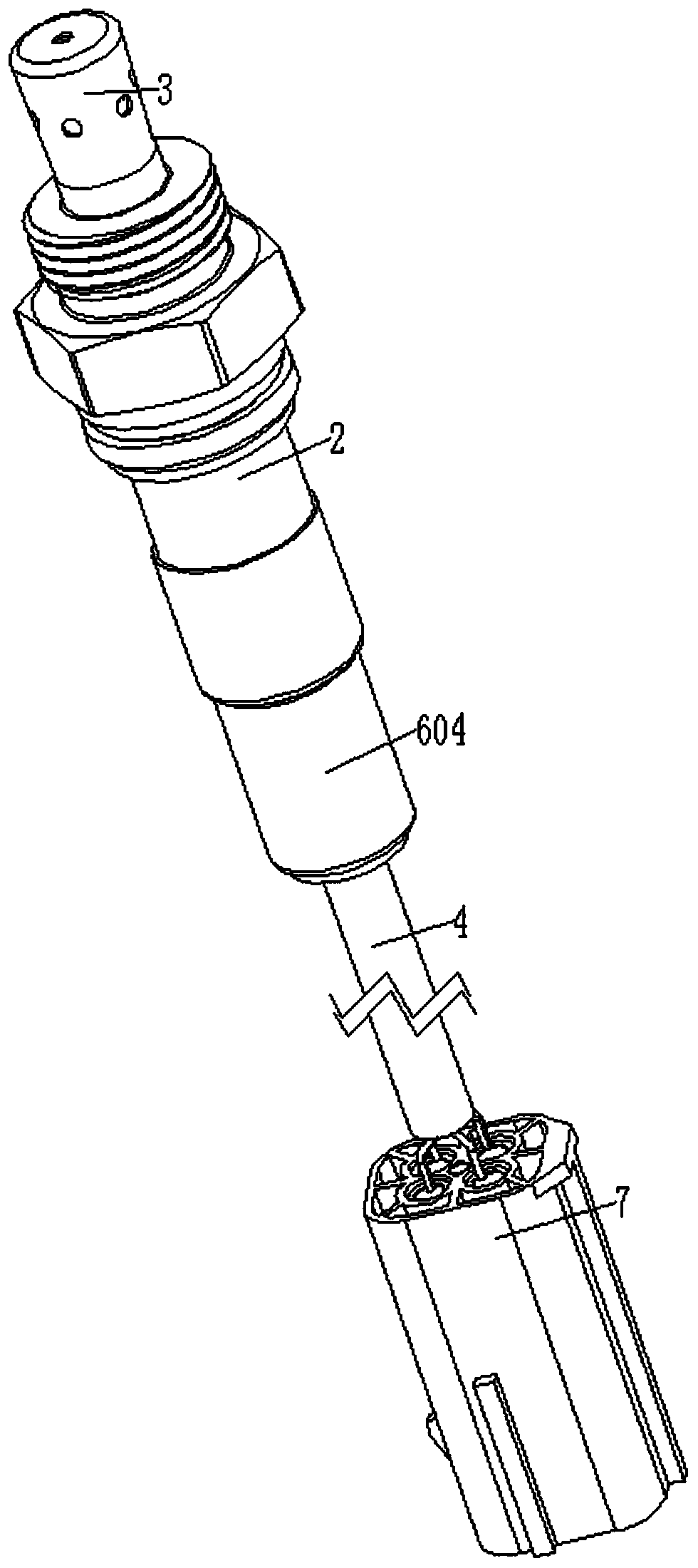

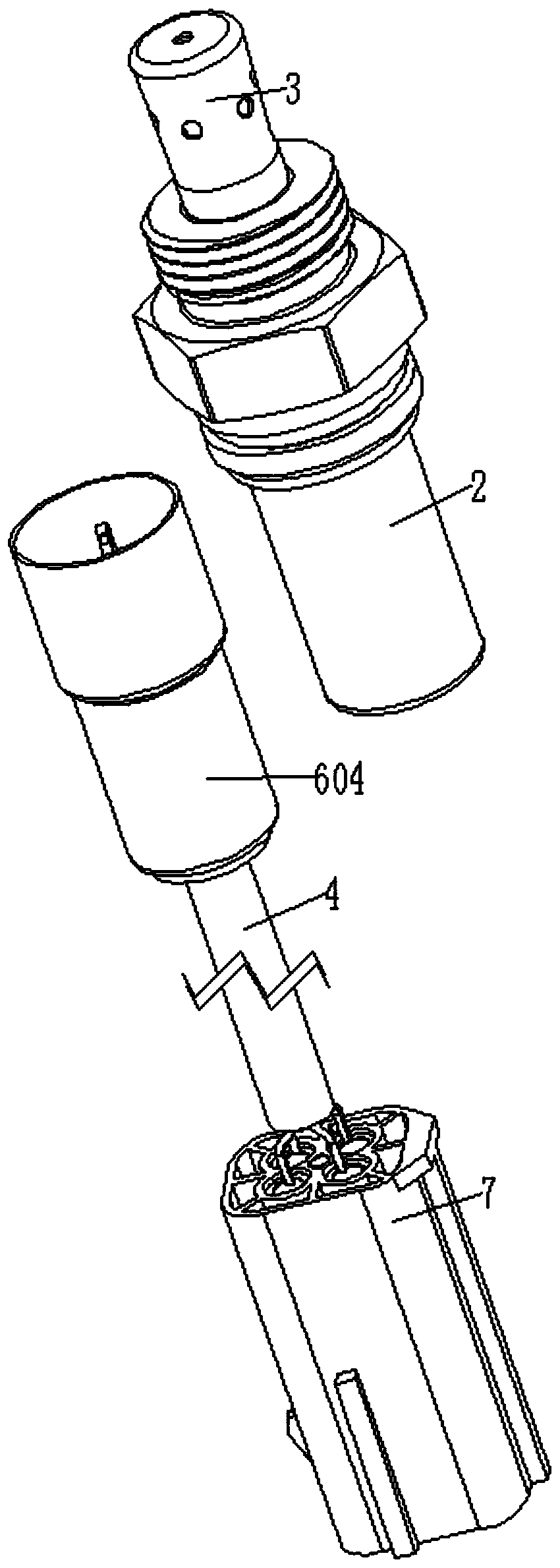

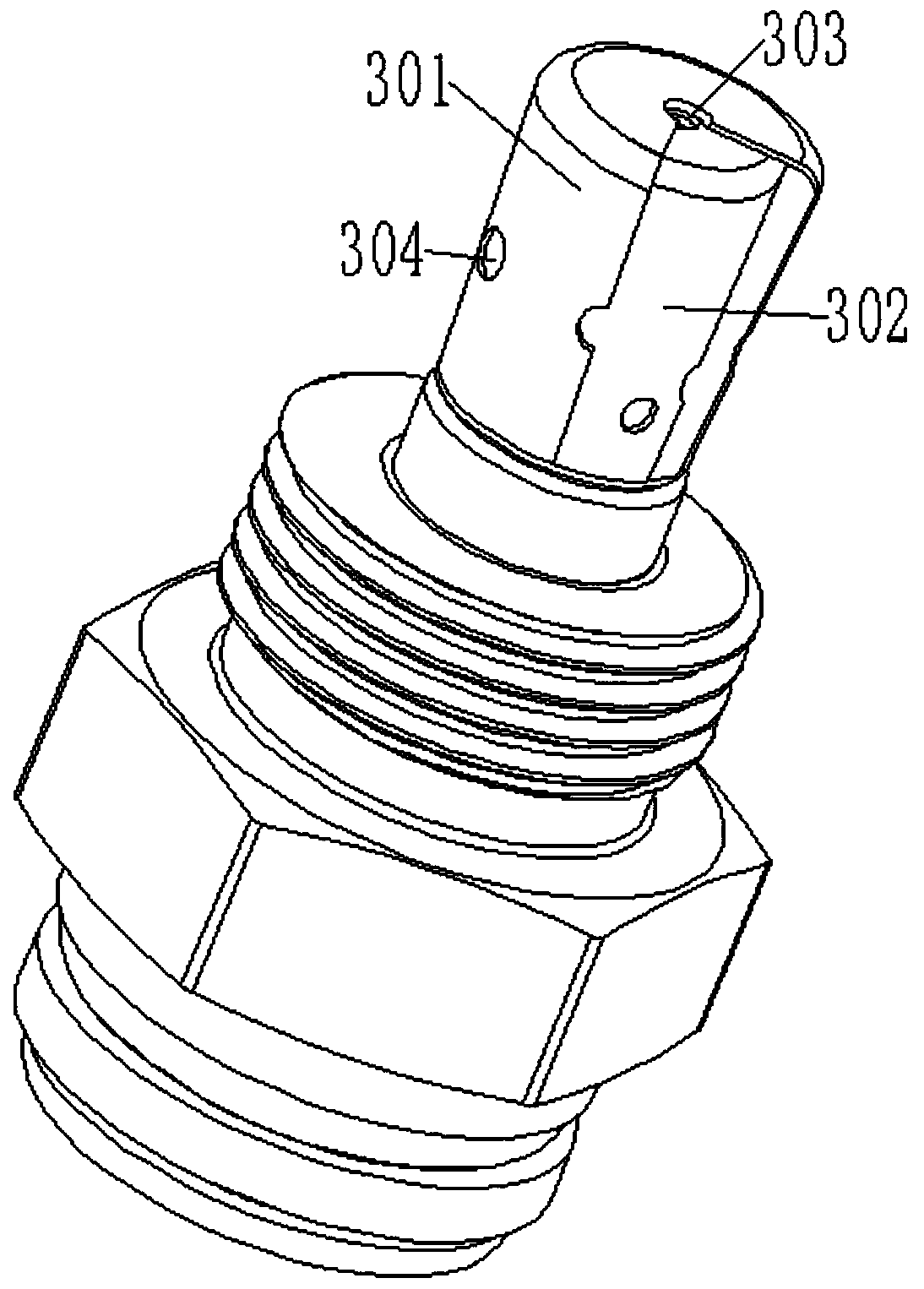

[0031] The present invention will be specifically described below in conjunction with the accompanying drawings, such as Figure 1-12As shown in the figure, the five-wire and five-plug oxygen sensor structure includes a chip 1 for detecting the oxygen ion content in the exhaust gas, a casing 2 for fixedly supporting the chip 1, and arranged at the head of the casing 2 to protect the chip 1 and surround the chip 1. The short shield 3 for sampling the chip 1 from the exhaust gas is arranged on the signal wire 4 connected to the chip 1 through a cable at the tail of the casing 2, and the spring joint 6 between the chip 1 and the signal wire 4 is arranged. The connector 7 at the other end of the signal wire 4, wherein the chip 1 includes a main board 101, a sensing piece 102 arranged at the head of the main board 101, and a contact electrode 103 arranged at the tail of the main board 101, and the sensing piece 102 is used for sensing automobile exhaust gas The oxygen ion content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com