A magnetic sheet based on amorphous or nanocrystalline ribbon and its preparation method

A technology of nanocrystalline strips and magnetic sheets, applied in the manufacture of inductors/transformers/magnets, preventing/reducing unwanted electrical/magnetic influences, components of transformers/inductors, etc. The range of magnetic permeability of the sheet, the inability to control the gap between the thin sheets well, and the influence of the normal use of the magnetic sheet, etc., can improve the charging efficiency, accurately control the magnetic permeability, and achieve the effect of low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

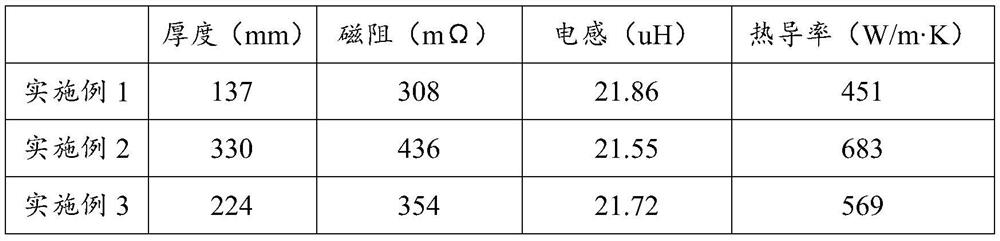

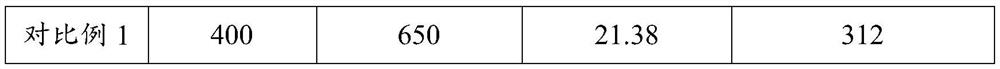

Embodiment 1

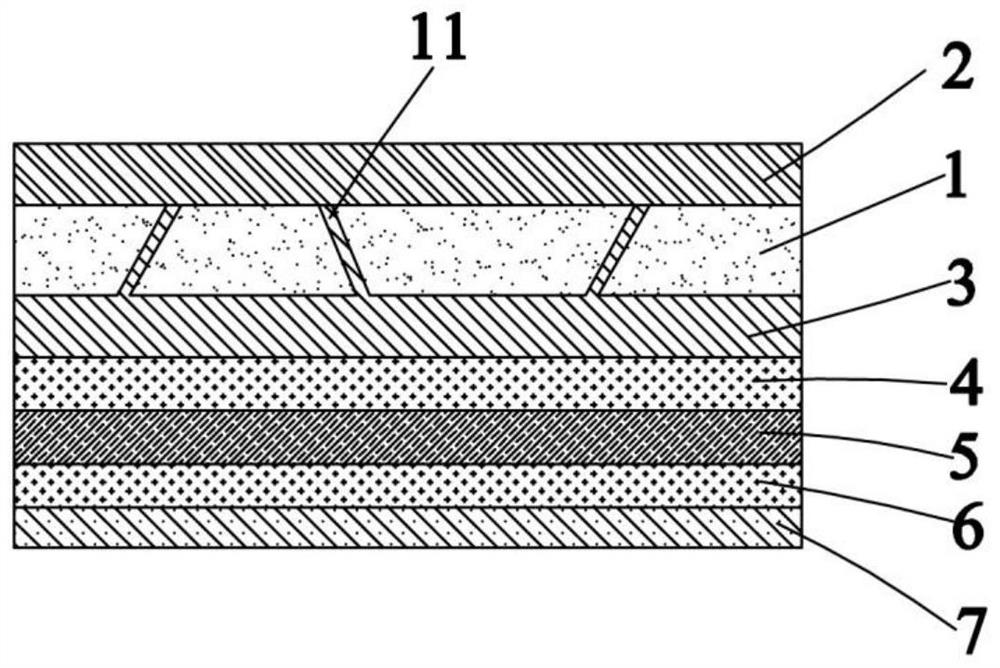

[0035] Preparation of Magnetic Flakes Based on Amorphous or Nanocrystalline Ribbons:

[0036] First, the amorphous or nanocrystalline ribbon with a thickness of 100 μm is heat-treated and crushed to obtain an amorphous or nanocrystalline ribbon with a scaly structure; secondly, polytetrafluoroethylene, hydroxyethyl acrylate, thermally conductive filler, iron Hydrogen phosphate and deionized water are mixed to make an insulating thermally conductive glue, and poured on one side of an amorphous or nanocrystalline strip with a scale-like structure, and part of the insulating thermally conductive glue is filled in the gaps of the scale-like structure to form An insulating and thermally conductive adhesive layer with a thickness of 0.01 μm, and another part of the insulating and thermally conductive adhesive solution is evenly coated on the surface of the amorphous or nanocrystalline strip to form an insulating and thermally conductive adhesive layer with a thickness of 3 μm. Among ...

Embodiment 2

[0038] Preparation of Magnetic Flakes Based on Amorphous or Nanocrystalline Ribbons:

[0039]First, the amorphous or nanocrystalline ribbon with a thickness of 100 μm is heat-treated and crushed to obtain an amorphous or nanocrystalline ribbon with a scaly structure; secondly, polytetrafluoroethylene, hydroxyethyl acrylate, thermally conductive filler, iron Hydrogen phosphate and deionized water are mixed to make an insulating thermally conductive glue, and poured on one side of an amorphous or nanocrystalline strip with a scale-like structure, and part of the insulating thermally conductive glue is filled in the gaps of the scale-like structure to form An insulating and thermally conductive adhesive layer with a thickness of 1 μm, and another part of the insulating and thermally conductive adhesive solution is evenly coated on the surface of the amorphous or nanocrystalline strip to form an insulating and thermally conductive adhesive layer with a thickness of 20 μm. Among the...

Embodiment 3

[0041] Preparation of Magnetic Flakes Based on Amorphous or Nanocrystalline Ribbons:

[0042] First, the amorphous or nanocrystalline ribbon with a thickness of 100 μm is heat-treated and crushed to obtain an amorphous or nanocrystalline ribbon with a scaly structure; secondly, polytetrafluoroethylene, hydroxyethyl acrylate, thermally conductive filler, iron Hydrogen phosphate and deionized water are mixed to make an insulating thermally conductive glue, and poured on one side of an amorphous or nanocrystalline strip with a scale-like structure, and part of the insulating thermally conductive glue is filled in the gaps of the scale-like structure to form An insulating and thermally conductive adhesive layer with a thickness of 0.05 μm, and another part of the insulating and thermally conductive adhesive solution is evenly coated on the surface of the amorphous or nanocrystalline strip to form an insulating and thermally conductive adhesive layer with a thickness of 10 μm. Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com