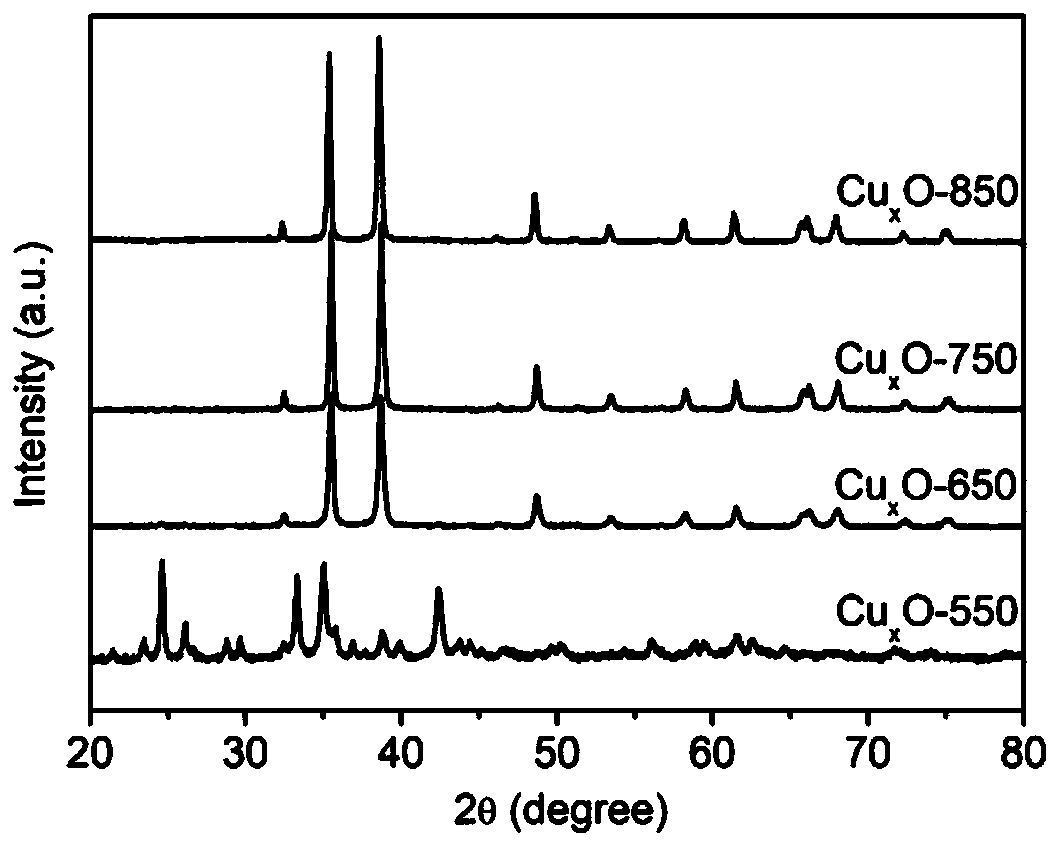

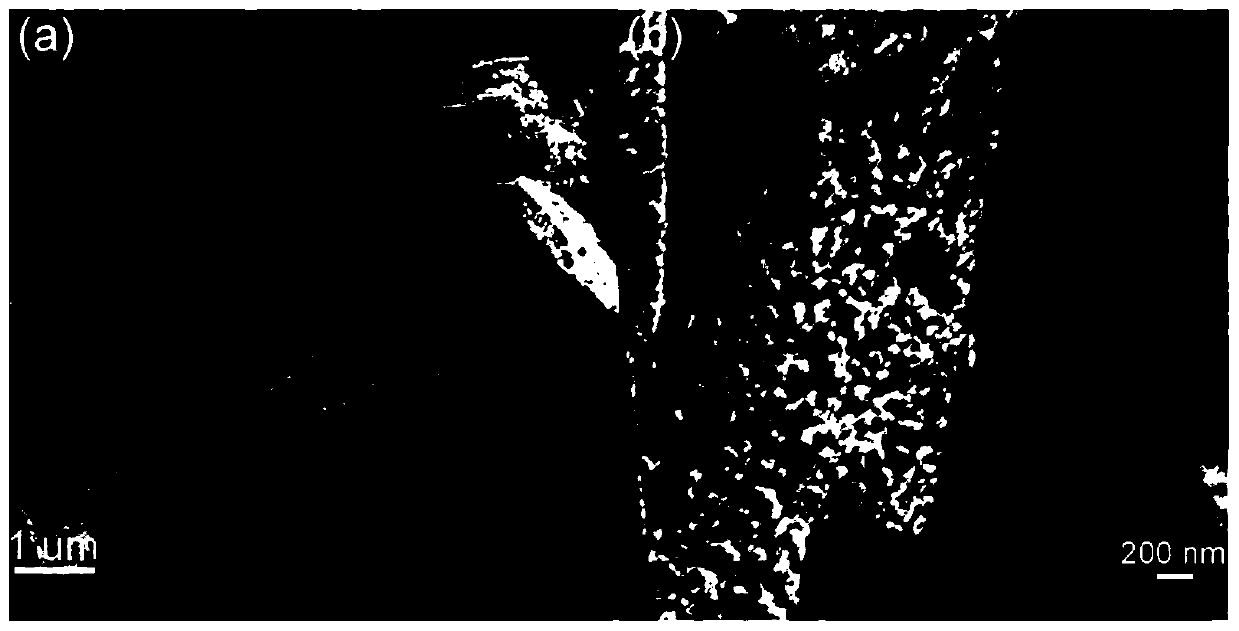

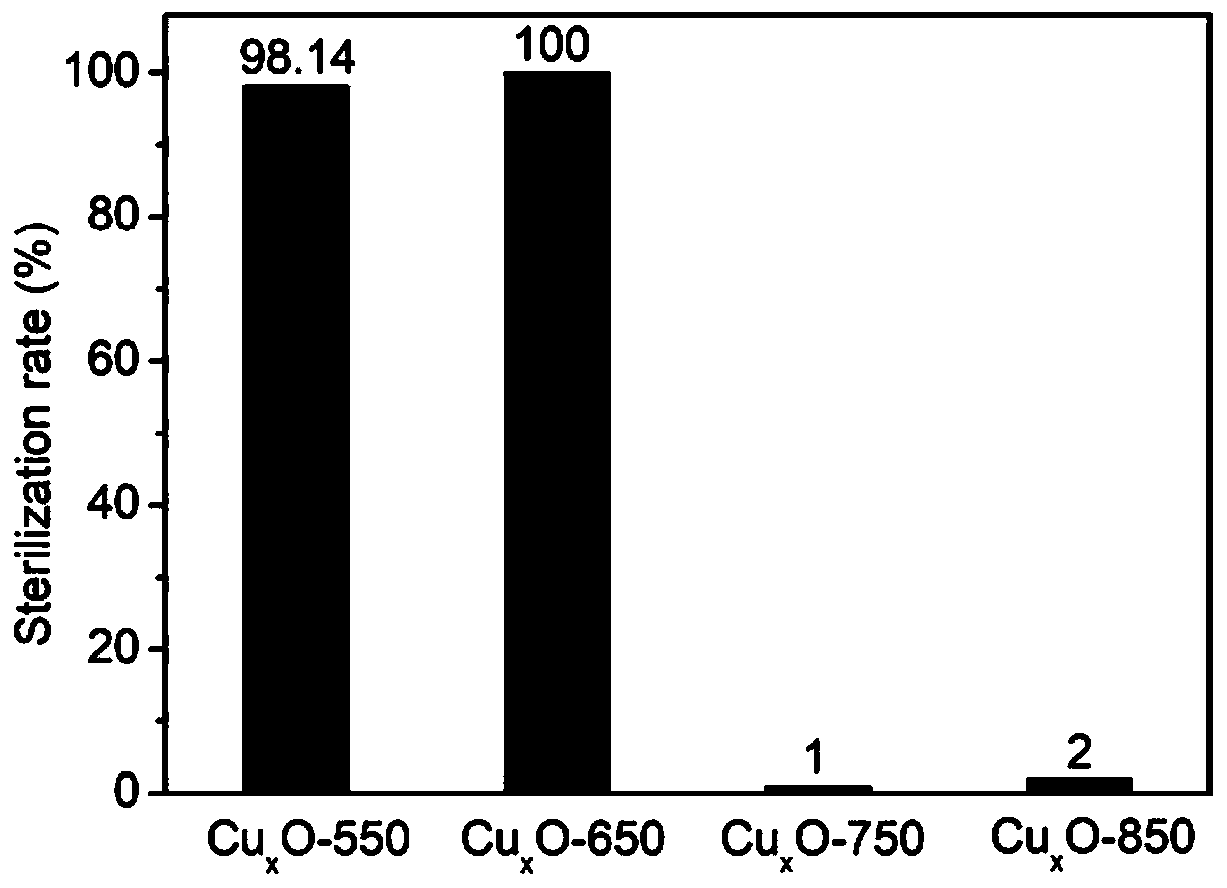

Rod-like CuxO photocatalytic material as well as preparation method and application thereof

A photocatalytic material and rod-shaped technology, applied in the field of photocatalytic materials, can solve the problems of low photocatalytic antibacterial efficiency and high cost, and achieve the advantages of large-scale industrial production, good antibacterial effect, and improved visible light photocatalytic antibacterial performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A rod-shaped Cu x The preparation method of O photocatalytic material, comprises the following steps:

[0031] (1) Add anhydrous copper sulfate, cetyltrimethylammonium bromide and water into a beaker, stir well to obtain a mixed solution; the concentration of anhydrous copper sulfate in the mixed solution is 0.01 ~ 2.00 mol / L, cetyl The concentration of alkyltrimethylammonium bromide is 0.001 ~ 0.1 mol / L;

[0032] (2) Add the egg film into the above beaker, stir evenly to obtain a suspension, the concentration of the egg film in the suspension is 0.1-10mg / mL;

[0033] Wherein, the treatment method of the egg membrane is as follows: take out the egg white and egg yolk from the egg to obtain the eggshell, remove the egg membrane in the eggshell by physical stripping, wash the egg membrane with deionized water, dry it, and cut it into a size of 1 ~ 1.2 cm × 1 ~ 1.2 cm;

[0034] (3) Transfer the suspension above to the eggshell, then place the eggshell in a beaker filled...

Embodiment 1

[0039] A rod-shaped Cu x The preparation method of O photocatalytic material, comprises the following steps:

[0040] (1) Add anhydrous copper sulfate, cetyltrimethylammonium bromide and water into a beaker, stir well to obtain a mixed solution; the concentration of anhydrous copper sulfate in the mixed solution is 0.01 mol / L, cetyl The concentration of trimethylammonium bromide is 0.1 mol / L;

[0041] (2) Add the egg film into the above beaker, stir evenly to obtain a suspension, the concentration of the egg film in the suspension is 2.5mg / mL;

[0042] (3) Transfer the suspension above to eggshells, then place the eggshells in a beaker filled with 1 mol / L sodium hydroxide solution, and transfer the beaker to an oil bath, and place in an oil bath at 50 °C React for 96 hours;

[0043](4) Centrifuge the solution obtained after the reaction, collect the product, wash it with distilled water and ethanol in sequence, and dry it to obtain a sample;

[0044] (5) The above samples ...

Embodiment 2

[0046] A rod-shaped Cu x The preparation method of O photocatalytic material, comprises the following steps:

[0047] (1) Add anhydrous copper sulfate, cetyltrimethylammonium bromide and water into a beaker, stir well to obtain a mixed solution; the concentration of anhydrous copper sulfate in the mixed solution is 0.01 mol / L, cetyl The concentration of trimethylammonium bromide is 0.15 mol / L;

[0048] (2) Add the egg film into the above beaker, stir evenly to obtain a suspension, the concentration of the egg film in the suspension is 2.5mg / mL;

[0049] (3) Transfer the suspension above to eggshells, then place the eggshells in a beaker filled with 1 mol / L sodium hydroxide solution, and transfer the beaker to an oil bath, and place in an oil bath at 50 °C React for 96 hours;

[0050] (4) Centrifuge the solution obtained after the reaction, collect the product, wash it with distilled water and ethanol in sequence, and dry it to obtain a sample;

[0051] (5) The above sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com