C3N5 material as well as preparation method and application thereof

A C3N5, mixing technology, applied in the field of photocatalysis, achieves the effect of good photocatalytic activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention C 3 N 5 The preparation method of material, comprises the steps:

[0028] a. Mixing: Mix 3-amino-1,2,4-triazole and six-membered nitrogen heterocycle at a weight ratio of 1:0.8 to 1.2 to obtain a mixed powder, wherein the six-membered nitrogen heterocycle is At least one of cyanuric acid and barbituric acid;

[0029] b. Calcination: Heat the mixed powder at 480-520°C for 2.5-3.5 hours, take it out after cooling, wash and dry to obtain C 3 N 5 Material.

[0030]Step a is mainly to mix the raw materials according to the proportion. Preferably, the specific operation of step a is: add 3-amino-1,2,4-triazole and six-membered nitrogen heterocycle to absolute ethanol, stir for 1~ 3h, then sonicate for 0.5-1.5h, and dry at 60-80°C to obtain a mixed powder; preferably stir for 2h, then sonicate for 1h, and dry at 70°C.

[0031] As one of the implementations, in step a, the six-membered nitrogen heterocycle is cyanuric acid. Preferably, 3-amino-1,2,4...

Embodiment 1

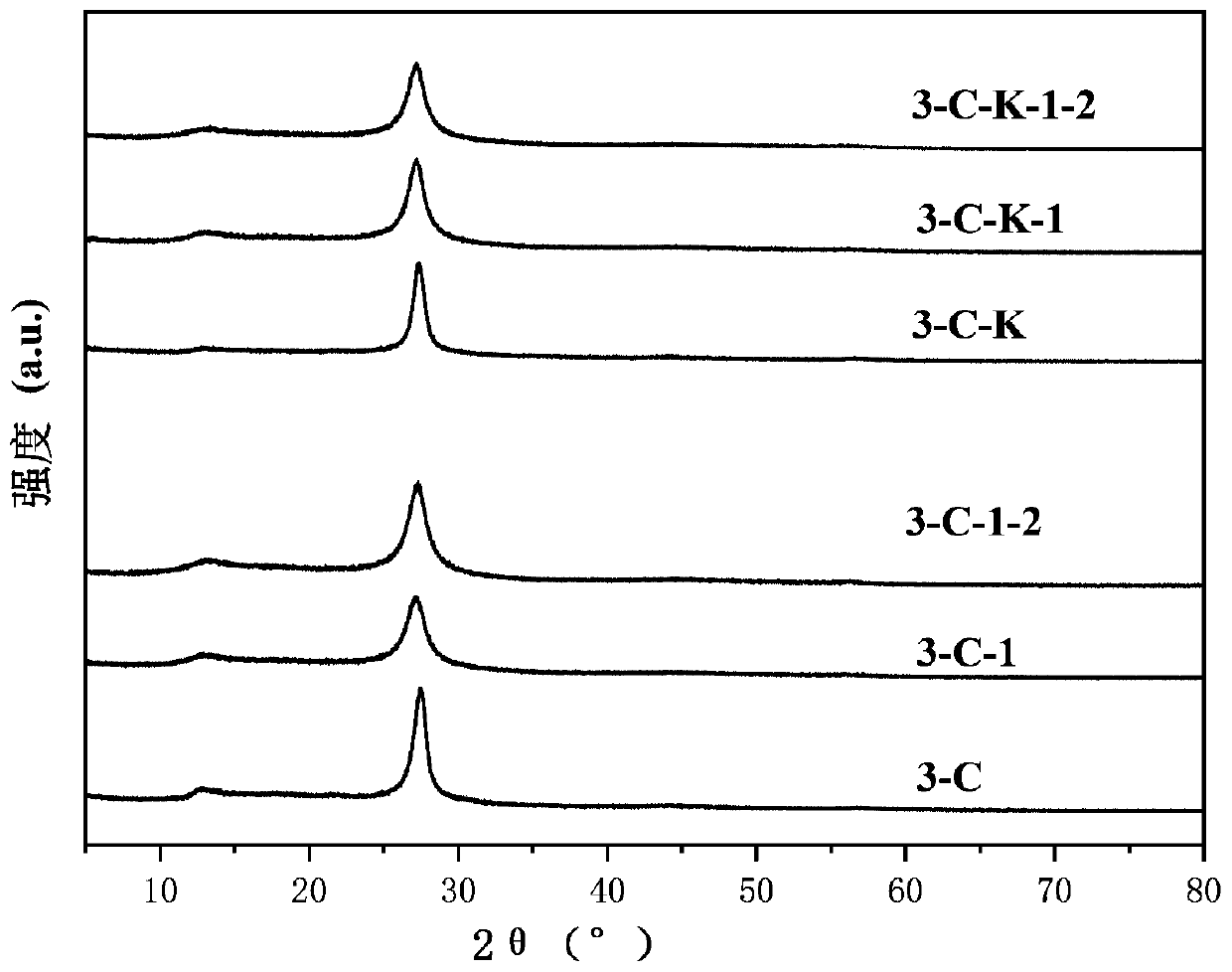

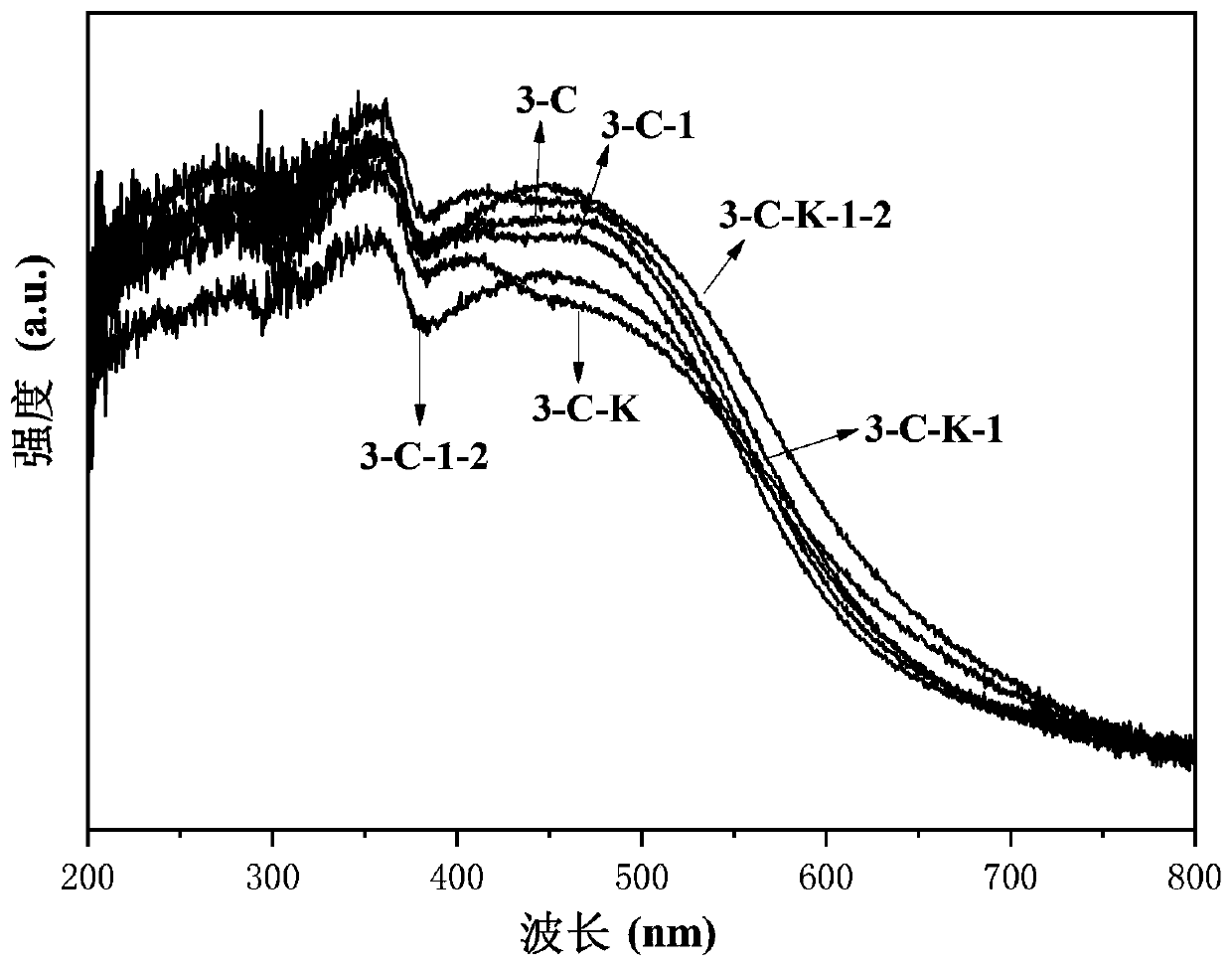

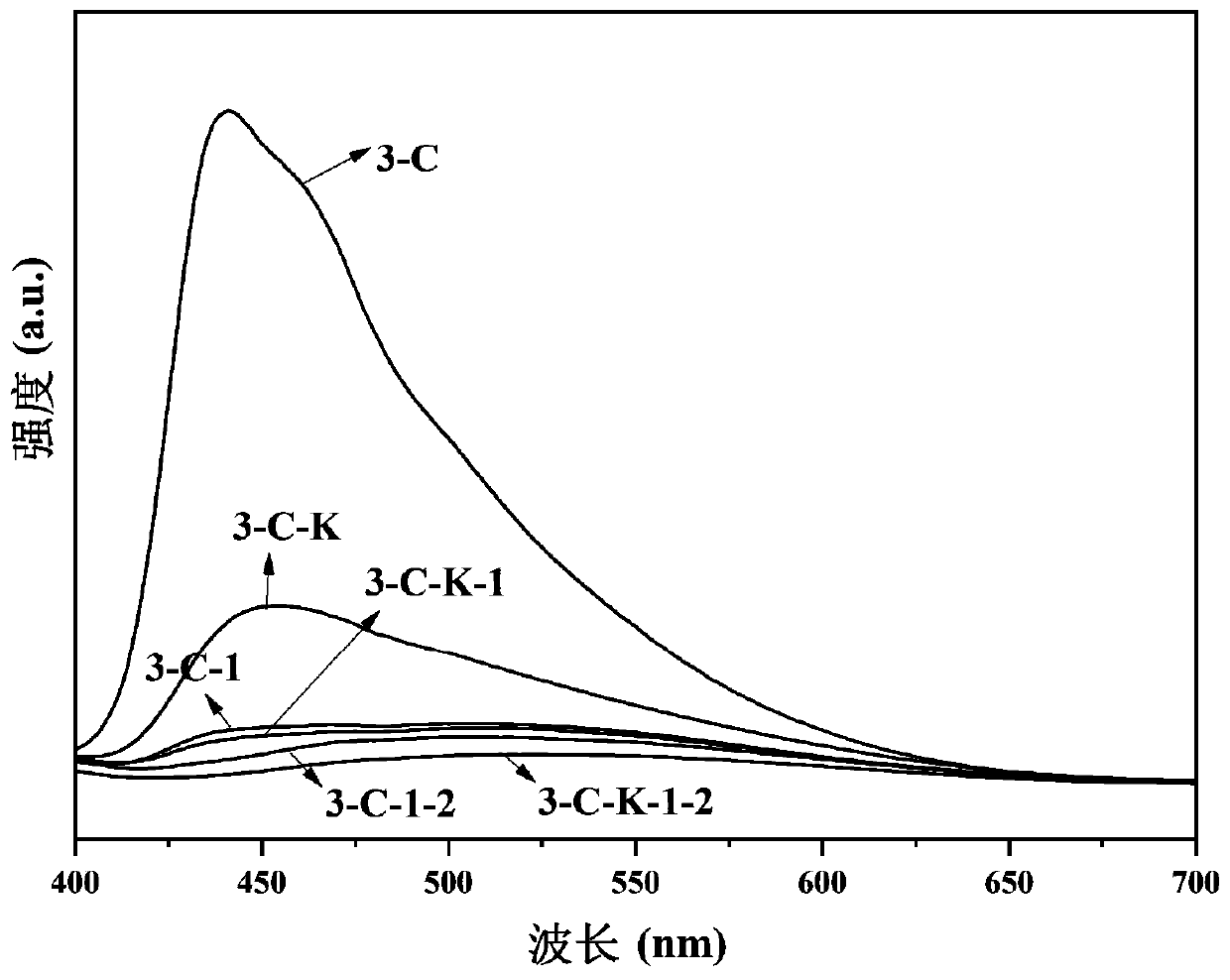

[0043] Weigh 5g of 3-amino-1,2,4-triazole and 5g of cyanuric acid into a beaker and add 100mL of absolute ethanol, then stir the suspension at ambient temperature for 2h, then sonicate at room temperature Processing 1h. Then the suspension was dried in an oven at 70°C to obtain a powder, which was put into a 50mL crucible with a lid, moved to a muffle furnace at a rate of 5°C / min to 500°C and then kept for 3 hours. After cooling, put the sample into a beaker and add 100mL of distilled water, then put it into an ultrasonic machine for ultrasonic dispersion for 3h, then centrifuge and dry the sample to obtain C 3 N 5 Materials, recorded as 3-C-1. The XRD pattern of the material is shown in figure 1 , UV diffuse reflectance spectrum see figure 2 , the fluorescence emission spectrum under 366nm excitation is shown in image 3 .

Embodiment 2

[0045] Weigh 5g of 3-amino-1,2,4-triazole, 5g of cyanuric acid and 0.5g of barbituric acid into a beaker and add 100mL of absolute ethanol, then put the suspension at ambient temperature Stir for 2 h, then sonicate for 1 h at room temperature. Then the suspension was dried in an oven at 70 °C to obtain a white powder, which was put into a 50 mL crucible with a lid, moved to a muffle furnace at a heating rate of 5 °C / min to 500 °C and then kept for 3 h. After cooling, put the sample into a beaker and add 100mL of distilled water, then put it into an ultrasonic machine for ultrasonic dispersion for 3h, then centrifuge and dry the sample to obtain C 3 N 5 Materials, denoted as 3-C-1-2. The XRD pattern of the material is shown in figure 1 , UV diffuse reflectance spectrum see figure 2 , the fluorescence emission spectrum under 366nm excitation is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com