Air return circulation type coating oven water solvent coating heat recycle system and operation method

A recovery system and heat recovery technology, applied in separation methods, chemical instruments and methods, devices for coating liquid on surfaces, etc., can solve the problem of uneven operation of the coating machine, no recovery of pure water, and low efficiency of heat recovery methods and other problems, to achieve the effect of easy process management, efficient recovery, and reduced operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

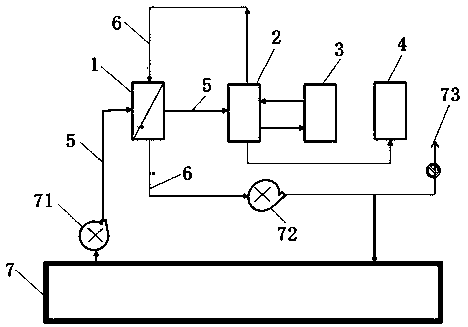

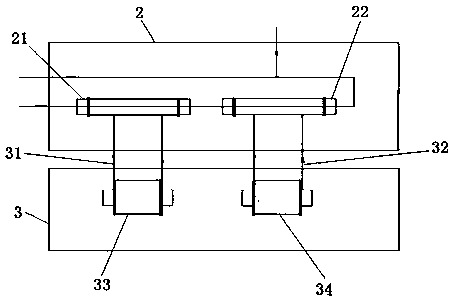

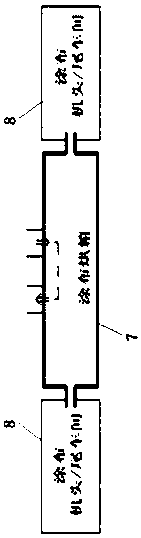

[0021] Such as Figure 1-2 As shown, the return air circulation coating oven water solvent coating heat recovery system includes a coating oven 7, a pre-cooling heat recovery system 1, a condensed solvent recovery system 2 and a storage system 4; the coating oven 7 passes through the gas pipe The road is connected to the pre-cooling heat recovery system 1, one end of the condensed solvent recovery system 2 is connected to the pre-cooling heat recovery system 1, and the other end of the condensed solvent recovery system 2 is connected to the storage system 4; The pre-cooling heat recovery system 1 and the condensed solvent recovery system 2 are all provided with a coating oven exhaust gas inlet 5 and a coating oven e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com