Preparation methods of bisphenol A modified phenolic resin and modified phenolic resin molding material

A technology of phenolic resin and molding compound, applied in the field of polymer synthesis and modification, can solve the problem of oxidative discoloration of phenolic molding compound, and achieve the effect of good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

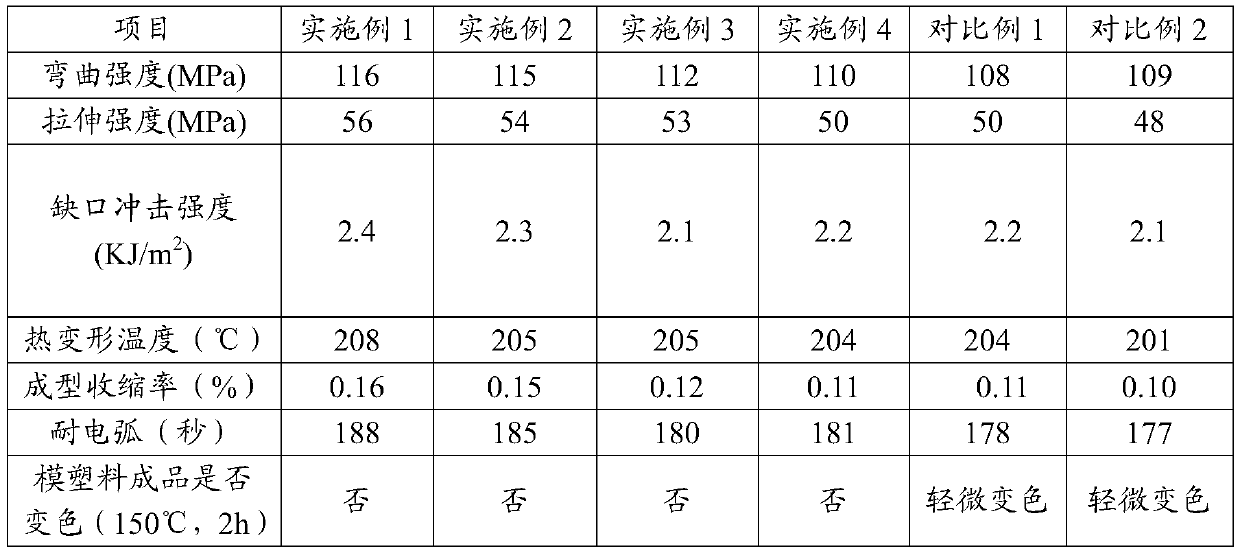

Examples

preparation example Construction

[0024] A method for preparing bisphenol A modified phenolic resin according to an embodiment of the present invention includes the following steps:

[0025] 1) Phenol and acid are added to the reaction kettle, stirred, and heated to 80-90°C to obtain the reaction liquid;

[0026] 2) Add formaldehyde gradually to the reaction solution obtained in step 1), and control the reaction temperature to be 85-95°C, react for 0.5-2h to obtain the reaction solution;

[0027] 3) Gradually add bisphenol A to the reaction solution obtained in step 2), raise the temperature to 90-120°C, and react for 0.5-2h;

[0028] 4) Gradually add melamine to the reaction solution obtained in step 3), and react for 1-3h;

[0029] 5) Dehydration under reduced pressure to obtain modified phenolic resin.

[0030] Preferably, in the above-mentioned preparation method of bisphenol A modified phenolic resin, the formaldehyde is an aqueous formaldehyde solution, and the molar ratio of formaldehyde to phenol is 0.6-0.95.

[0...

Embodiment 1

[0043] A preparation method of bisphenol A modified phenolic resin, including:

[0044] 1) Measure 100g of phenol and 3g of oxalic acid into the reactor, stir, and raise the temperature to 85°C;

[0045] 2) Add 55 g of 37% formaldehyde aqueous solution gradually to the reaction solution obtained in step 1), and control the reaction temperature to 90°C, and react for 1 hour;

[0046] 3) Gradually add 20g of bisphenol A to the reaction solution obtained in step 2), raise the temperature to 110°C, and react for 1.5 hours;

[0047] 4) Gradually add 10g of melamine to the reaction solution obtained in step 3), and react for 2h;

[0048] 5) Dehydration under reduced pressure to obtain modified phenolic resin.

[0049] A preparation method of modified phenolic resin molding compound, including:

[0050] (1) 30 parts of bisphenol A modified phenolic resin, 25 parts of carbon fiber, 15 parts of calcium carbonate, 1 part of titanium blue, 20 parts of curing agent, 5 parts of stearic acid, 1,3,5-tri...

Embodiment 2

[0053] A preparation method of bisphenol A modified phenolic resin, including:

[0054] 1) Measure 100g of phenol and 3g of acetic acid into the reactor, stir, and raise the temperature to 90°C;

[0055] 2) Add 60 g of 37% formaldehyde aqueous solution gradually to the reaction solution obtained in step 1), and control the reaction temperature to 95° C., and react for 1 hour;

[0056] 3) Gradually add 30g of bisphenol A to the reaction solution obtained in step 2), raise the temperature to 110°C, and react for 1.5h;

[0057] 4) Gradually add 20 g of melamine to the reaction solution obtained in step 3), and react for 2 hours;

[0058] 5) Dehydration under reduced pressure to obtain modified phenolic resin.

[0059] A preparation method of modified phenolic resin molding compound, including:

[0060] (1) 40 parts of bisphenol A modified phenolic resin, 30 parts of carbon fiber, 10 parts of talc, 2 parts of titanium blue, 10 parts of curing agent, 3 parts of stearic acid, 1,3,5-trimethyl A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com