High-performance flame-retardant ABS composite material and preparation method thereof

A composite material and high-performance technology, which is applied in the field of high-performance flame-retardant ABS composite materials and its preparation, can solve problems such as difficult application and difficult to pass the needle flame test, and achieve high production efficiency, unique green and environmental protection characteristics, and easy industrialization. The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

[0028] The preparation method of ABS composite material in the embodiment of the present invention is:

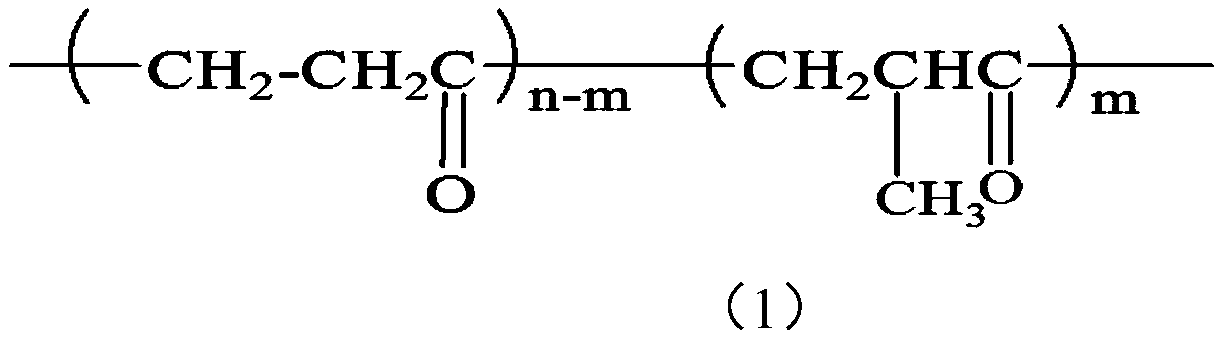

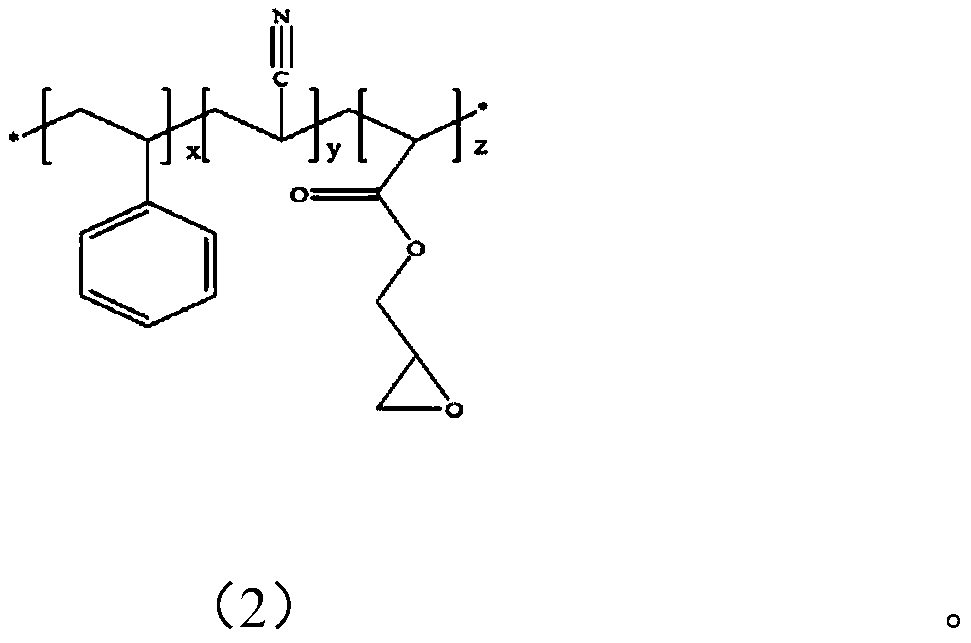

[0029] (1) Mix ABS resin, POK polyketone resin, brominated flame retardant, antimony flame retardant, compatibilizer and processing aid in a high-speed mixing mixer in proportion or enter the dual In the screw extruder;

[0030] (2) Under the conveying, mixing and shearing action of the twin-screw extruder, the ingredients in the formula are fully melted and plasticized, kneaded and mixed, extruded through the machine head, drawn, cooled, pelletized, dried and packaged, Obtain the new high-performance flame-retardant ABS composite material; wherein, the temperature of each section of the twin-screw extruder from the feeding port to the machine head is respectively: the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com