High-toughness cast aluminum-silicon alloy and waste aluminum regeneration method thereof

A technology for casting aluminum-silicon alloy and aluminum-silicon alloy, which is applied in the field of high-strength and toughness casting aluminum-silicon alloy and its waste aluminum regeneration, and can solve problems such as waste of precious metal elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

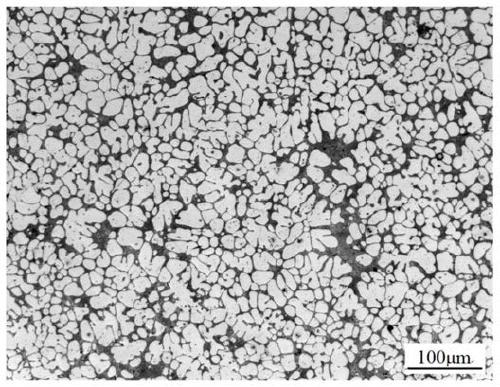

Embodiment 1

[0049] A method for recycling waste aluminum of high-strength and tough cast aluminum-silicon alloys, said method comprising the steps of:

[0050] (1) select the raw material of following mass percentage: 61% aluminum-silicon alloy waste, 21% aluminum-magnesium alloy waste, 11% aluminum-copper alloy waste, 4.4% aluminum-zinc alloy waste, 2% aluminum-manganese alloy waste, 0.3% aluminum titanium carbon alloy, 0.15% aluminum strontium alloy and 0.15% aluminum boron alloy;

[0051] Among them, the chemical composition and mass percentage of aluminum-silicon alloy waste are: Si 11.8%, Cu 0.4%, Ni 0.3%, Fe 0.58%, the balance is Al and other impurity elements, and the individual content of other impurity elements is ≤0.1%, and the total amount is ≤ 0.5%;

[0052] The chemical composition and mass percentage of aluminum-magnesium alloy scrap are: Mg 2.1%, Cr 0.2%, Fe 0.26%, the balance is Al and other impurity elements, the individual content of other impurity elements is ≤0.05%, a...

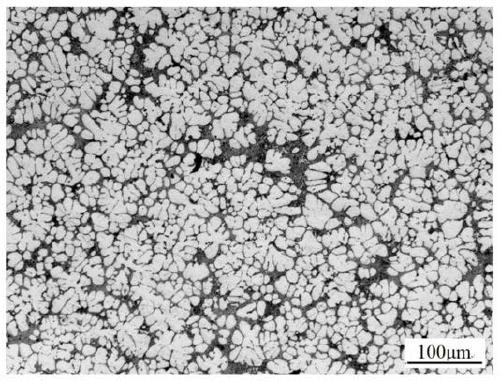

Embodiment 2

[0067] A method for recycling waste aluminum of high-strength and tough cast aluminum-silicon alloys, said method comprising the steps of:

[0068] (1) select the following raw materials in mass percentage: 59% aluminum-silicon alloy waste, 21% aluminum-magnesium alloy waste, 11.6% aluminum-copper alloy waste, 6% aluminum-zinc alloy waste, 2% aluminum-manganese alloy waste, 0.2% aluminum titanium carbon alloy, 0.1% aluminum strontium alloy and 0.1% aluminum boron alloy;

[0069] Among them, the chemical composition and mass percentage of aluminum-silicon alloy waste are: Si 11.0%, Cu 0.3%, Ni 0.1%, Fe 0.44%, the balance is Al and other impurity elements, the individual content of other impurity elements is ≤0.1%, and the total amount is ≤ 0.5%;

[0070] The chemical composition and mass percentage of aluminum-magnesium alloy scrap are: Mg 3.0%, Cr 0.3%, Fe 0.34%, the balance is Al and other impurity elements, the individual content of other impurity elements is ≤0.05%, and th...

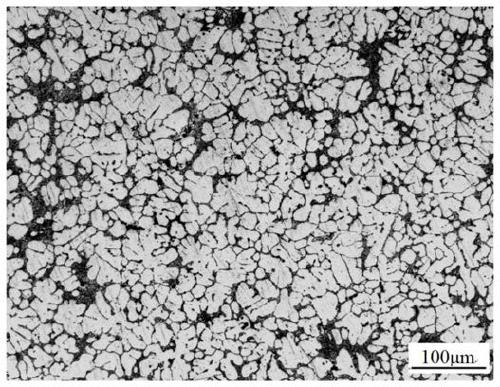

Embodiment 3

[0085] A method for recycling waste aluminum of high-strength and tough cast aluminum-silicon alloys, said method comprising the steps of:

[0086] (1) select the raw material of following mass percentage: 59% aluminum-silicon alloy waste, 21% aluminum-magnesium alloy waste, 11% aluminum-copper alloy waste, 6% aluminum-zinc alloy waste, 2.2% aluminum-manganese alloy waste, 0.4% aluminum titanium carbon alloy, 0.2% aluminum strontium alloy and 0.2% aluminum boron alloy;

[0087] Among them, the chemical composition and mass percentage of aluminum-silicon alloy waste are: Si 11.4%, Cu0.1%, Ni 0.3%, Fe 0.59%, the balance is Al and other impurity elements, and the individual content of other impurity elements is ≤0.1%, the total ≤0.5%;

[0088] The chemical composition and mass percentage of aluminum-magnesium alloy scrap are: Mg 2.6%, Cr 0.2%, Fe 0.38%, the balance is Al and other impurity elements, and the individual content of other impurity elements is ≤0.05%, and the total a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com