Method for monitoring and analyzing rebound of positive pole piece of lithium ion battery and lithium ion battery

A technology of lithium ion battery and positive pole piece, which is used in the analysis of the rebound of the positive pole piece of lithium ion battery, the characterization of lithium ion battery material test, and the monitoring field, which can solve the problem of lack of strong support, high cost, and change in thickness of the positive pole piece. Lack of in-depth and clear understanding and other issues to achieve the effect of saving R&D costs and speeding up the R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

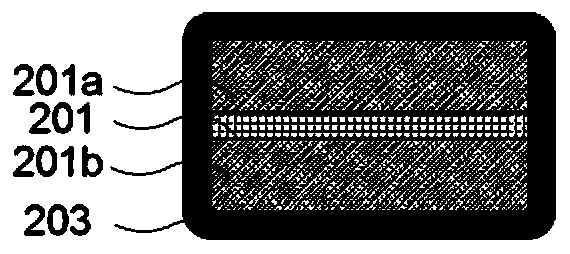

[0101] Prepare the lithium ion battery of the present invention as follows, wherein:

[0102] Positive electrode: the positive electrode foil is metal aluminum foil with a specification of 0.012×666mm; the positive electrode coating material is: nickel cobalt lithium manganate ternary single crystal positive electrode material A, carbon nanotubes (CNTs), conductive agent SP and polyvinylidene fluoride ( PVDF) is prepared according to the weight ratio of 96.2:1.2:1.6:1.0, and the compacted density is 3.45g / cm 3 . Wherein, the positive electrode coating material is double-coated on the positive electrode foil material aluminum foil.

[0103] The diaphragm material is: a polyethylene diaphragm with a specification of 12 μm × 88 mm.

[0104] Electrolyte: LiPF 6 The concentration is 1.1mol / L, the solvent is diethyl carbonate (DEC), ethylene carbonate (EC), ethyl methyl carbonate (EMC), containing vinylene carbonate (VC), ethylene sulfate (DTD), etc. Other types of additive elec...

Embodiment 2

[0112] In addition to making the compacted density of nickel-cobalt lithium manganate ternary single-crystal positive electrode material A from 3.45g / cm 3 down to 2.85g / cm 3 Except, the above test was carried out under the same conditions as in Example 1. The change curve of the corresponding rebound rate of the positive pole piece with the charge and discharge cycle is as follows: Figure 6 shown.

[0113] The physical rebound, chemical rebound and overall rebound of the positive pole piece all increase with the increase of the number of cycles. At the same time, the physical rebound and chemical rebound of the positive electrode are distinguished. Compared with the results in Example 1, there is basically no change in the chemical rebound, while the physical rebound and the overall rebound have a certain decline. This is because the compaction density becomes smaller, and there are more voids in the pole piece, which can accommodate more physical rebound. At the same tim...

Embodiment 3

[0115] The above test was carried out under the same conditions as in Example 1, except that nickel-cobalt lithium manganese oxide ternary polycrystalline positive electrode material B was used instead of nickel-cobalt lithium manganese oxide ternary single-crystal positive electrode material A. Among them, nickel-cobalt lithium manganese oxide ternary polycrystalline positive electrode material B is a secondary particle obtained by compound granulation of primary particles (primary particle diameter D50 value is 280nm), the overall shape of the secondary particles is spherical, material B The particle size D50 value is 9.65 μm, and the surface of the material is not coated. The change curve of the corresponding rebound rate of the positive pole piece with the charge and discharge cycle is as follows: Figure 7 shown.

[0116] The physical rebound, chemical rebound and overall rebound of the positive pole piece all increase with the increase of the number of cycles. At the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com