Preparation method of nickel-based heterogeneous catalyst and application of nickel-based heterogeneous catalyst to hydrodeoxygenation reaction of catalytic aldehyde compound

A compound and catalyst technology, which is applied to the preparation of nickel-based heterogeneous catalysts and its application in the field of catalyzing the hydrodeoxygenation of aldehyde compounds, can solve the problems of expensive precious metal catalysts, etc. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

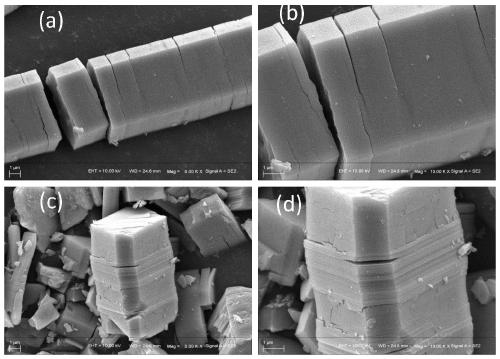

[0023] 1. Preparation of nickel-based heterogeneous catalyst porous material Ni-MFC-X

[0024] 1) Add 0.0582 nickel nitrate hexahydrate, 1.108g of organic ligand and 15ml of water into the hydrothermal synthesis kettle by hydrothermal synthesis method, and then program the temperature up to the target temperature of 180°C with a heating rate of 2°C / min. Burn for three days and cool down for three days to room temperature to synthesize a metal precursor Ni-MFC green needle-like crystal;

[0025] 2) These metal precursor Ni-MFC crystals were calcined in a tube furnace under nitrogen for 4h at a calcination temperature of 500°C to obtain a nickel-based catalyst Ni-MFC-500 with good thermal stability and cyclicity.

[0026] 3) These metal precursor Ni-MFC crystals were calcined in a tube furnace under nitrogen for 4h at a calcination temperature of 600°C to obtain a nickel-based catalyst Ni-MFC-600 with good thermal stability and recyclability.

[0027] 3) These metal precursor N...

Embodiment 2

[0036] Application of new porous material Ni-MFC-700 in hydrogenation reduction of 3,4,5-trimethoxybenzaldehyde:

[0037] With 3,4,5-trimethoxybenzaldehyde as substrate, 5mL methanol as solvent, add 0.01g of catalyst and 0.1g of 3,4,5-trimethoxybenzaldehyde, fill the reactor with 2MPa hydrogen, and Under the conditions of temperature of 175°C and stirring speed of 350 rpm, the reaction was carried out for 10 hours, and the reaction results were analyzed by gas chromatography; the conversion rate of 3,4,5-trimethoxybenzaldehyde was >85.9%, 3,4,5 - Yield of trimethoxytoluene 29.7%

[0038] With 3,4,5-trimethoxybenzaldehyde as substrate, 15mL of methanol as solvent, add 0.025g of catalyst and 0.1g of 3,4,5-trimethoxybenzaldehyde, fill the reactor with 2MPa hydrogen, and Under the condition of temperature of 200°C and stirring speed of 550 rpm, the reaction was carried out for 10 hours, and the reaction result was analyzed by gas chromatography; the conversion rate of 3,4,5-trime...

Embodiment 3

[0041] Application of the new porous material Ni-MFC-700 in the hydrogenation reduction of 3-hydroxy-4-methoxybenzaldehyde:

[0042] With 3-hydroxyl-4-methoxybenzaldehyde as substrate, 5mL methanol as solvent, add 0.01g of catalyst 0.1g of 3-hydroxyl-4-methoxybenzaldehyde, fill the reaction kettle with 2MPa hydrogen, and Under the conditions of temperature of 175°C and stirring speed of 350 rpm, the reaction was carried out for 10 hours, and the reaction results were analyzed by gas chromatography; the conversion rate of 3-hydroxy-4-methoxybenzaldehyde was >90.3%, and the conversion rate of 3-hydroxy-4 - Yield of methoxytoluene 59.0%.

[0043] With 3-hydroxyl-4-methoxybenzaldehyde as substrate, 15mL methanol as solvent, add 0.025g of catalyst 0.1g of 3-hydroxyl-4-methoxybenzaldehyde, charge 2MPa hydrogen in the reactor, Under the conditions of temperature of 200°C and stirring speed of 550 rpm, the reaction was carried out for 10 hours, and the reaction results were analyzed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com