Yarn printing device based on ring spinning frame, and yarn printing method thereof

A printing method and spinning frame technology, applied in the field of yarn printing, can solve problems such as low efficiency and complex structure, and achieve the effects of low energy consumption, shortened production process, and minimized pollution discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

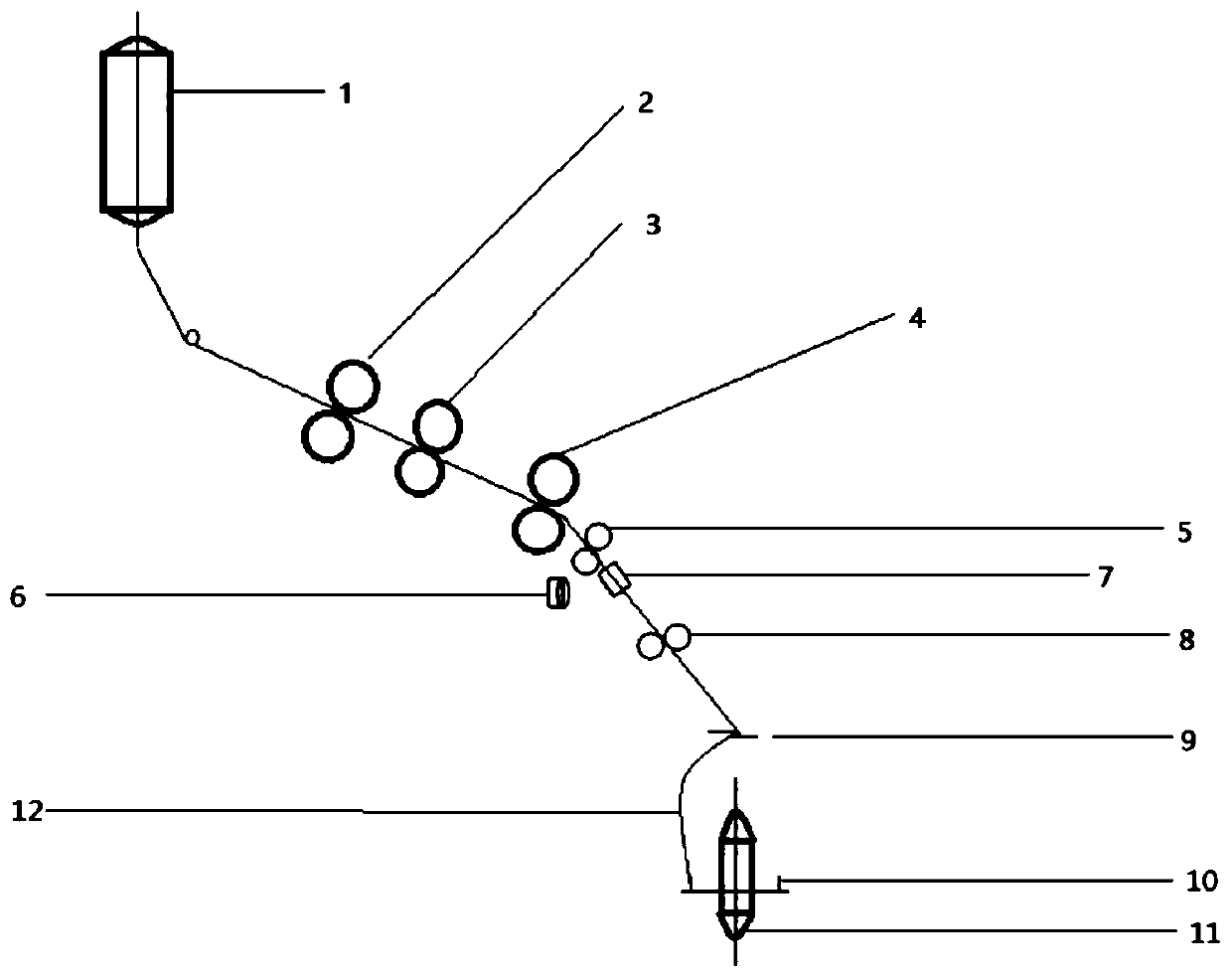

[0034] Such as figure 1 As shown, this embodiment provides a yarn printing device based on a ring spinning frame. The fiber strands are unwound from the roving bobbin 1 and enter the rear roller 2, and are weakly drafted between the rear roller 2 and the middle roller 3 , and then pulled out from the middle roller 3 into the front roller 4, between the middle roller 3 and the front roller 4, it is strongly drafted, and enters the area controlled by the yarn fixing back roller 5 and the yarn fixing front roller 8, and the printing nozzle 7 pairs of yarns Thread printing, the far-infrared heating lamp 6 preliminarily dries the dyed yarn, and the yarn is twisted and wound by the twist passed by the traveler 10 and the spun bobbin 11 through the yarn guide hook 9 to obtain the yarn 12.

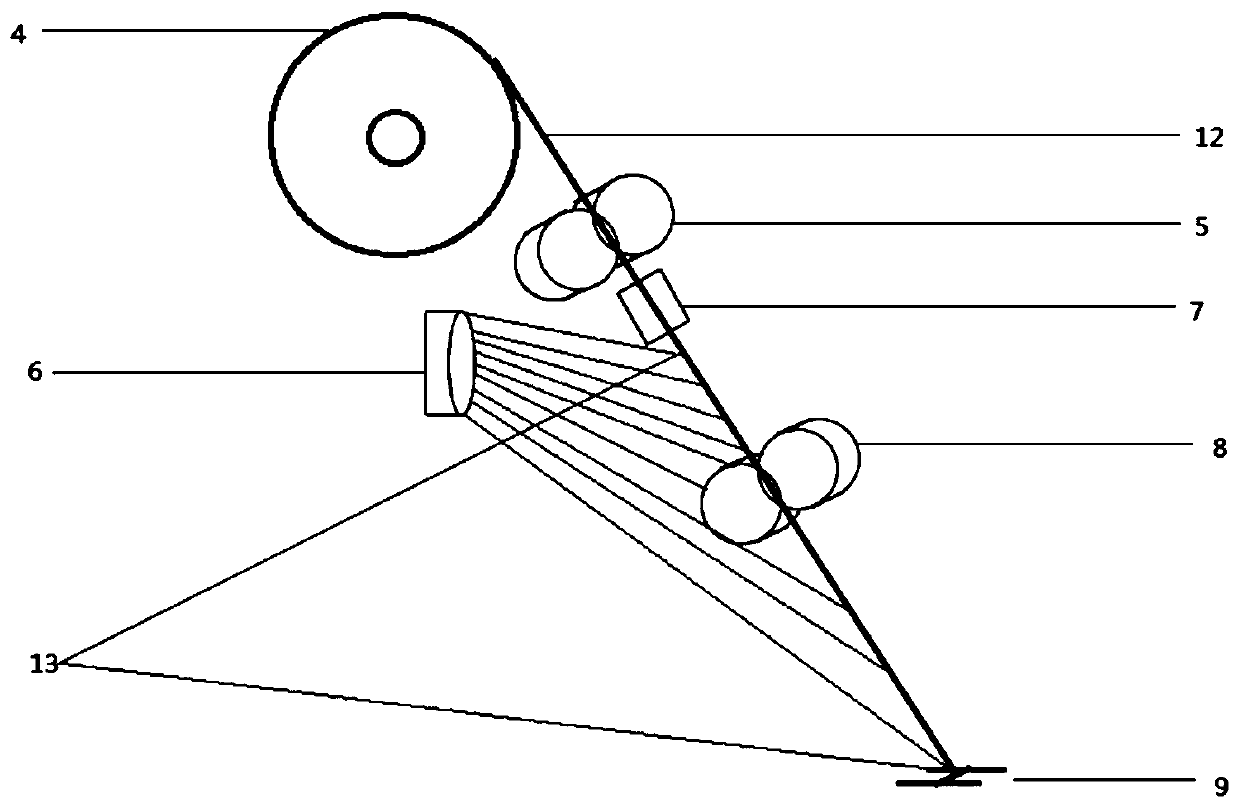

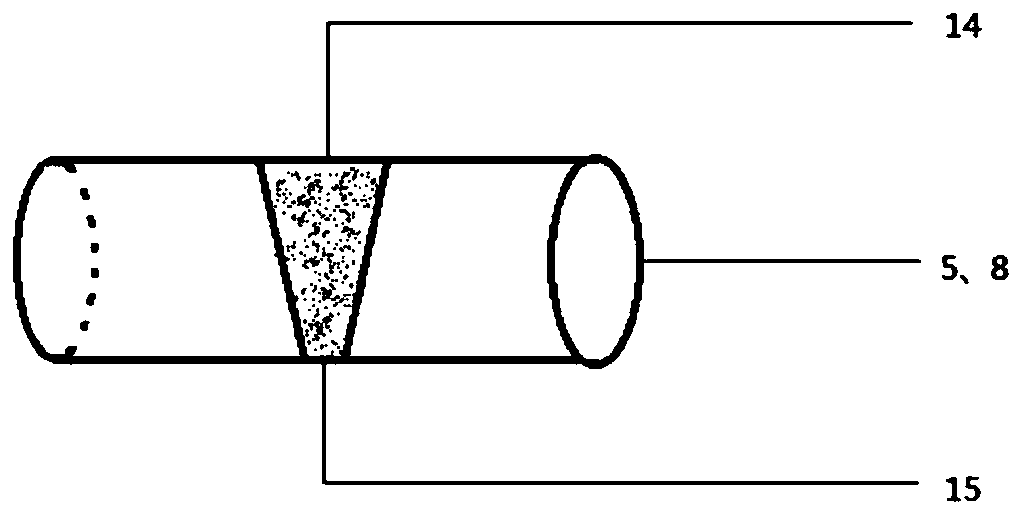

[0035] Such as figure 2 As shown, the yarn fixing rear roller 5 and the yarn fixing front roller 8 are two sets of rollers with angles, and the axes of the rollers are not parallel; the schemat...

Embodiment 2

[0038] This embodiment provides a printing yarn processing method of a yarn printing device of a ring spinning frame, the steps of which are as follows:

[0039] (1) Input the printed pattern of the designed printed yarn into the computer;

[0040] (2) Prepare the required paint and place it in the ink cartridge of the digital printing device;

[0041] (3) Preheating the far-infrared heating lamp 6 to raise its temperature to 170°C;

[0042] (4) Cotton yarn roving of specified count is unwound from the roving bobbin 1 on the roving creel hanging spindle, and fed into the drafting device for drafting through the guide rod and the slowly reciprocating and traversing guide bell mouth;

[0043] (5) The yarn passes through the rear roller 2, the middle roller 3, the front roller 4, the yarn fixing rear roller 5 in turn, and reaches the printing nozzle 7;

[0044] (6) The printing nozzle 7 carries out paint spray printing to the passed spun yarn, and the yarn passes through the no...

Embodiment 3

[0047] Pure cotton yarn with red and blue horizontal stripes.

[0048] Configure paint ink. Treat the pigment powder and grind it with a grinder for 5.5 hours to make the pigment particles the smallest and uniform in size, use a polymer dispersant and a surfactant propanol to adjust the viscosity of the color paste, and use a pH regulator to adjust the pH of the color paste , the ratio of each added ingredient and color paste is 14.2% of color paste, 3.7% of dispersant, 17.3% of surfactant, 1.6% of pH regulator, 0.7% of antibacterial agent, 0.03% of defoamer, and deionized water to supplement the remaining dose . Put the paint ink into the ink cartridge for backup.

[0049] Import the pattern design of horizontal red and blue colors into the digital printing nozzle control computer, configure the parameters of the digital printing machine, turn on the far-infrared heating lamp and preheat it to 170°C for standby.

[0050] Set the roller speed and spindle speed, and start th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com