Microcapsule antifouling agent, preparation method thereof, antifouling coating and preparation method thereof

An anti-fouling paint and microcapsule technology, applied in anti-fouling/underwater paints, coatings, paints containing biocides, etc., can solve the problems of short anti-fouling time, low solubility of capsaicin, and fast release of capsaicin , to achieve good inhibitory effect, simple preparation method, and prolong the effect of antifouling period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of the microcapsule antifouling agent described in the above technical solution, comprising the steps of:

[0033] mixing an alkaline buffer solution and a surfactant to obtain an aqueous phase;

[0034] Mix wolftoxin and oily solvent to obtain oily phase;

[0035] After the water phase and the oil phase are mixed, dopamine hydrochloride is added to carry out oxidative self-polymerization reaction to obtain the microcapsule antifouling agent.

[0036] The invention mixes the alkaline buffer solution and the surfactant to obtain the water phase.

[0037] In the present invention, the alkaline buffer solution is a Tris buffer solution with a pH value of preferably 8 to 9. The preparation method of the Tris buffer solution is not particularly limited in the present invention, and a suitable pH is obtained by using a conventional preparation method in the art. value. In the present invention, the Tris buffer soluti...

Embodiment 1

[0063] 150mL of Tris buffer solution with a pH value of 8.5 and 3g of cetyltrimethylammonium chloride were mixed to obtain an aqueous phase;

[0064] Mix 10mL of n-butanol and 0.1g of wolftoxin to obtain an oil phase;

[0065] After the water phase and the oil phase were mixed, 1 g of dopamine hydrochloride was added, stirred at room temperature (25° C.) at a speed of 400 rpm for 24 h, and then centrifuged at a speed of 10,000 rpm for 10 min to obtain a crude microcapsule antifouling agent, and then The crude microcapsule antifouling agent obtained by centrifugation was washed with deionized water for 3 times, and vacuum-dried at 45° C. to obtain the microcapsule antifouling agent.

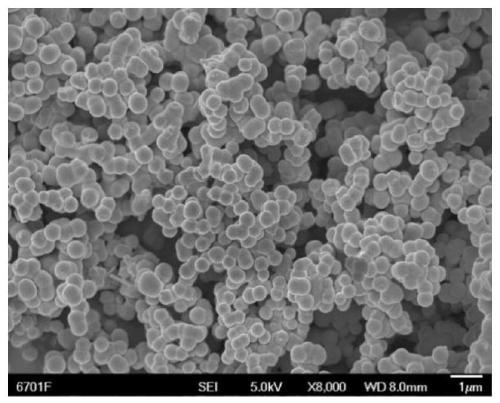

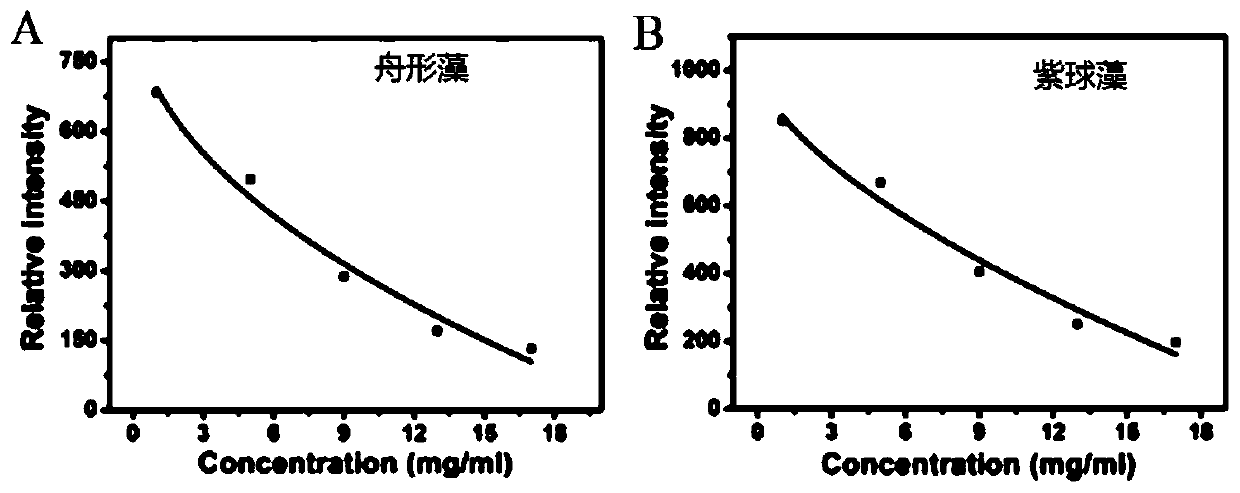

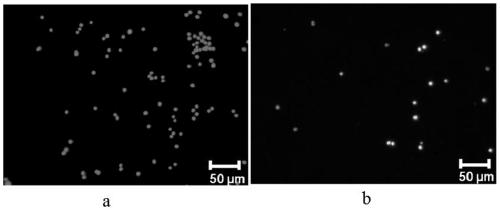

[0066] Use a UV-visible spectrophotometer to test the ultraviolet absorbance of wolftoxin in the microcapsule antifouling agent, and obtain its concentration through the ultraviolet absorbance of wolftoxin. Specifically, test the absorbance of wolftoxin at different concentrations to obtain the co...

Embodiment 2

[0070] The microcapsule antifouling agent was prepared according to the method of Example 1, except that the dosage of dopamine hydrochloride was 2 g.

[0071] Using the method in Example 1, it was detected that the loading of wolfram toxin was 75%.

[0072] The average particle size of the microcapsule antifouling agent obtained in this embodiment is 270nm by scanning electron microscopy, and the average wall thickness of the microcapsule antifouling agent obtained in this embodiment is 34nm by transmission electron microscopy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com