Waterborne polyurethane acrylate wood lacquer free of VOCs and preparation method thereof

A polyurethane acrylate and wood paint technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor coating adhesion and weather resistance, limited application, etc., to achieve convenient post-processing, controllable surface groups, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step (1): Preparation of waterborne polyurethane acrylate resin

[0040] Put 34 parts by weight of PTMG-2000 in a 250mL four-necked flask equipped with a mechanical stirrer, a thermometer, a condenser, and a dropping funnel, and vacuum dehydrate it in an oil bath at a temperature of 110°C for 90 minutes; after cooling down to 75°C, Under nitrogen protection, 40 parts by weight of isophorone diisocyanate and 0.5 parts by weight of dibutyltin dilaurate were slowly added dropwise, and the reaction was kept for 60 minutes under low-speed stirring; after the temperature was raised to 80°C, 6 parts by weight of 2 , 2-Dimethylol propionic acid, stirred at a constant speed and kept warm for 90 minutes until the theoretical NCO value of the prepolymer measured by di-n-butylamine titration was reached to obtain a hydrophilic polyurethane.

[0041]Cool down to 60°C, drop 12 parts by weight of hydroxyethyl methacrylate into the prepared hydrophilic polyurethane, and keep it at 60°C...

Embodiment 2

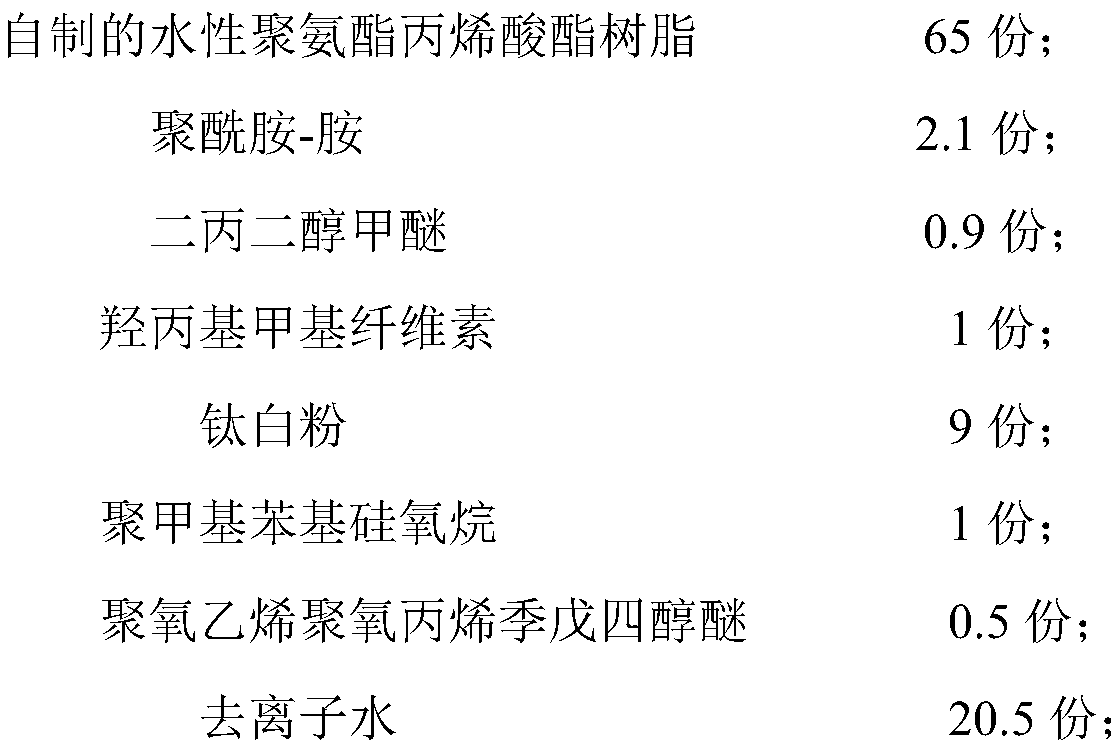

[0048] A zero-VOC water-based polyurethane acrylate wood lacquer and a preparation method thereof, is characterized in that the raw materials used for its preparation are calculated in parts by weight, and its composition and content are as follows:

[0049] Step (1): Preparation of waterborne polyurethane acrylate resin

[0050] Put 35 parts by weight of PTMG-2000 in a 250mL four-necked flask equipped with a mechanical stirrer, a thermometer, a condenser, and a dropping funnel, and vacuum dehydrate it in an oil bath at a temperature of 110°C for 90 minutes; after cooling down to 75°C, Under nitrogen protection, 40 parts by weight of isophorone diisocyanate and 0.5 parts by weight of dibutyltin dilaurate were slowly added dropwise, and the reaction was kept for 60 minutes under low-speed stirring; after the temperature was raised to 80°C, 6 parts by weight of 2 , 2-Dimethylol propionic acid, stirred at a constant speed and kept warm for 90 minutes until the theoretical NCO val...

Embodiment 3

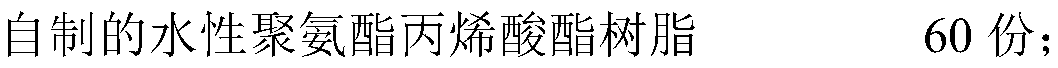

[0059] A zero-VOC water-based polyurethane acrylate wood lacquer and a preparation method thereof, is characterized in that the raw materials used for its preparation are calculated in parts by weight, and its composition and content are as follows:

[0060] Step (1): Preparation of waterborne polyurethane acrylate resin

[0061] Put 30 parts by weight of PTMG-2000 in a 250mL four-necked flask equipped with a mechanical stirrer, a thermometer, a condenser, and a dropping funnel, and vacuum dehydrate it in an oil bath at a temperature of 110°C for 90 minutes; after cooling down to 75°C, Under nitrogen protection, 40 parts by weight of isophorone diisocyanate and 0.5 parts by weight of dibutyltin dilaurate are slowly added dropwise, and the reaction is kept for 60 minutes under low-speed stirring; after the temperature is raised to 80°C, 7 parts by weight of 2 , 2-Dimethylol propionic acid, stirred at a constant speed and kept warm for 90 minutes until the theoretical NCO value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com