Synthesis method of semaglutide

A synthetic method, the technology of semaglutide, applied in the field of drug synthesis, to achieve the effect of reducing missing peptides, reducing the difficulty of synthesis, and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of synthetic method of semaglutide, such as Figure 4 shown, including the following steps:

[0046] 1.1 Synthesis of the first peptide resin

[0047] Weigh 100 g of 2-CTC resin with a substitution degree of 0.993 mmol / g, add it to a solid-phase reaction vessel, wash it twice with DCM, add DCM to swell for 30 min, and after the swelling is complete, the resin is decompressed and dried for use.

[0048] Fmoc-Gly-OH (8.92g, 30mmol) and DIEA (38.77g, 300mmol) were dissolved in DCM (500ml), and added to the above-mentioned 2-CTC resin to start the synthesis of Fmoc-Gly-resin after the dissolution and clarification, the reaction temperature Controlled at 25-30°C, reacted for 3h. After the reaction was complete, the resin was washed twice with DCM, 500ml each time. Then add methanol / DCM=1 / 4 (500) and DIEA (129.13g, 1000mmol) to the resin, capping at 25-30°C for 1h, wash the resin twice with DCM after capping, 500ml each time, add methanol to shrink the resin and dr...

Embodiment 2

[0074] The difference between this example and Example 1 is that the condensing agent system in Example 1 is changed to DIC+HOAt, and 97.89 g of semaglutide with a purity of 81.12% of crude semaglutide is obtained by the same scale and method .

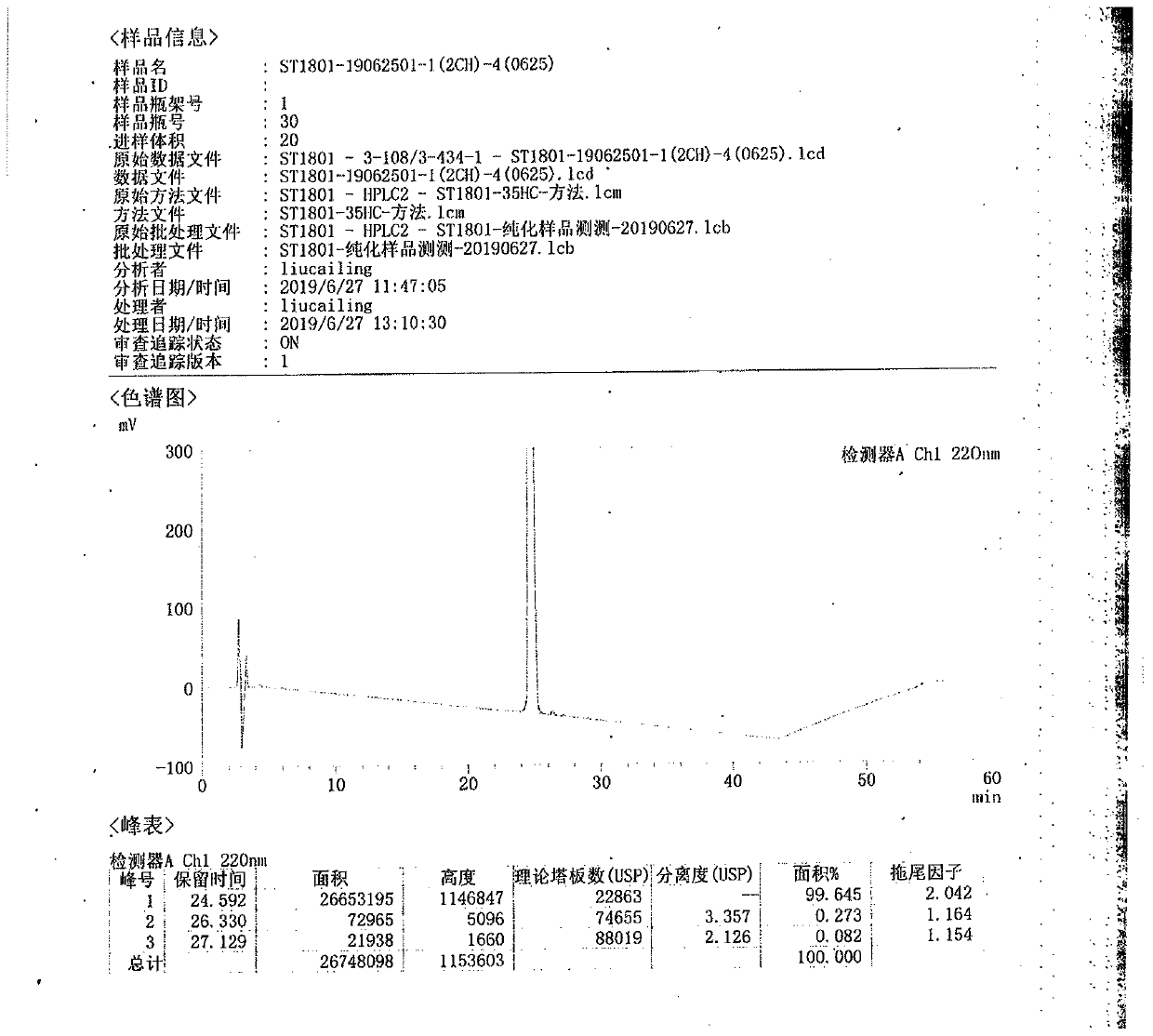

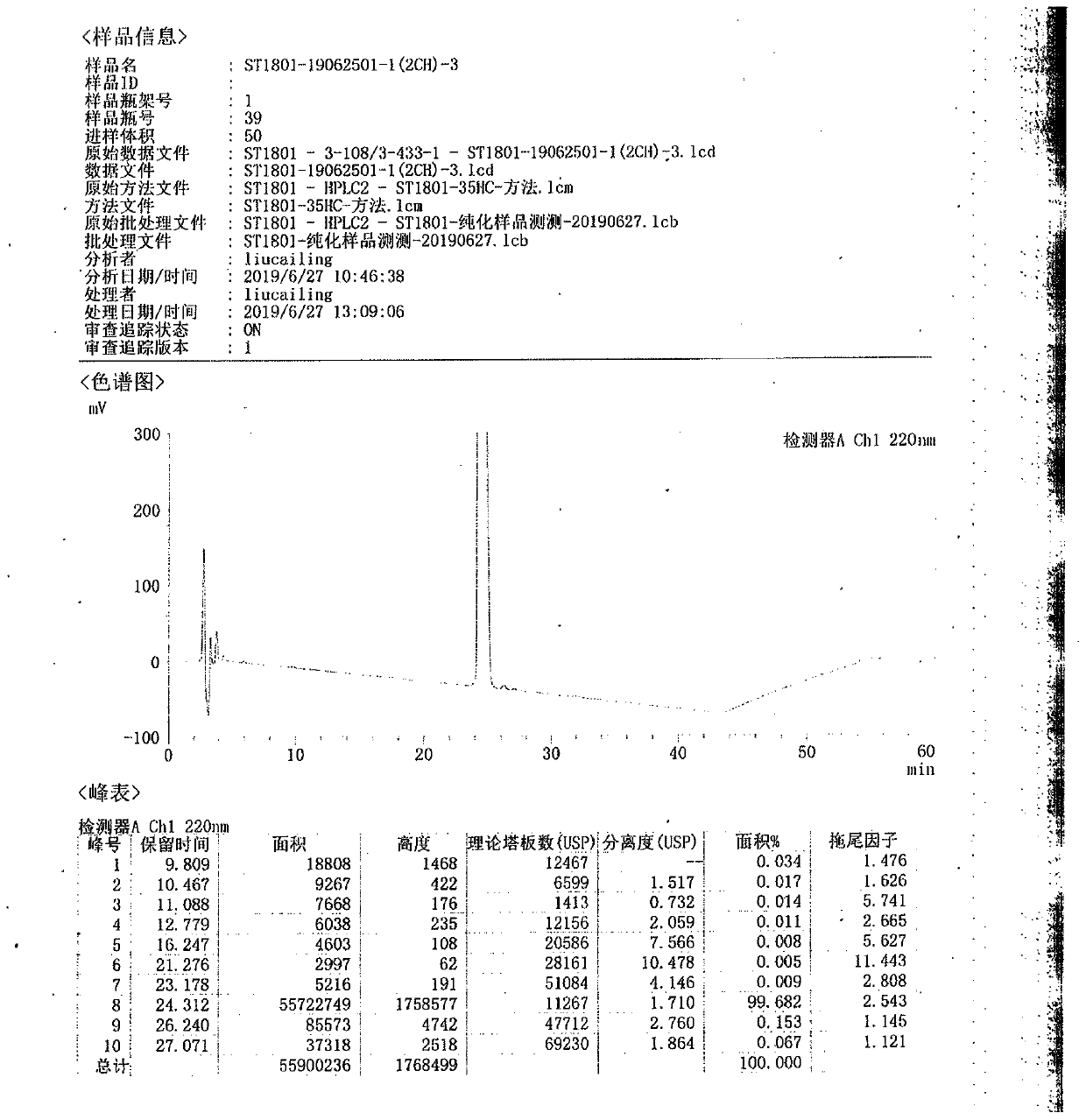

[0075] The pure product of semaglutide obtained by the same purification method in Example 1 is as follows: figure 2 As shown, the purity was 99.682%, and 1.12 g of pure semaglutide was obtained after purification of 2 g of crude semaglutide, with a yield of 56.15%.

Embodiment 3

[0077] The difference between this example and Example 1 is that the condensing agent system was changed to DIC+Cl-HOBt, and 106.23 g of semaglutide crude peptide with a purity of 83.12% was obtained by the same scale and method.

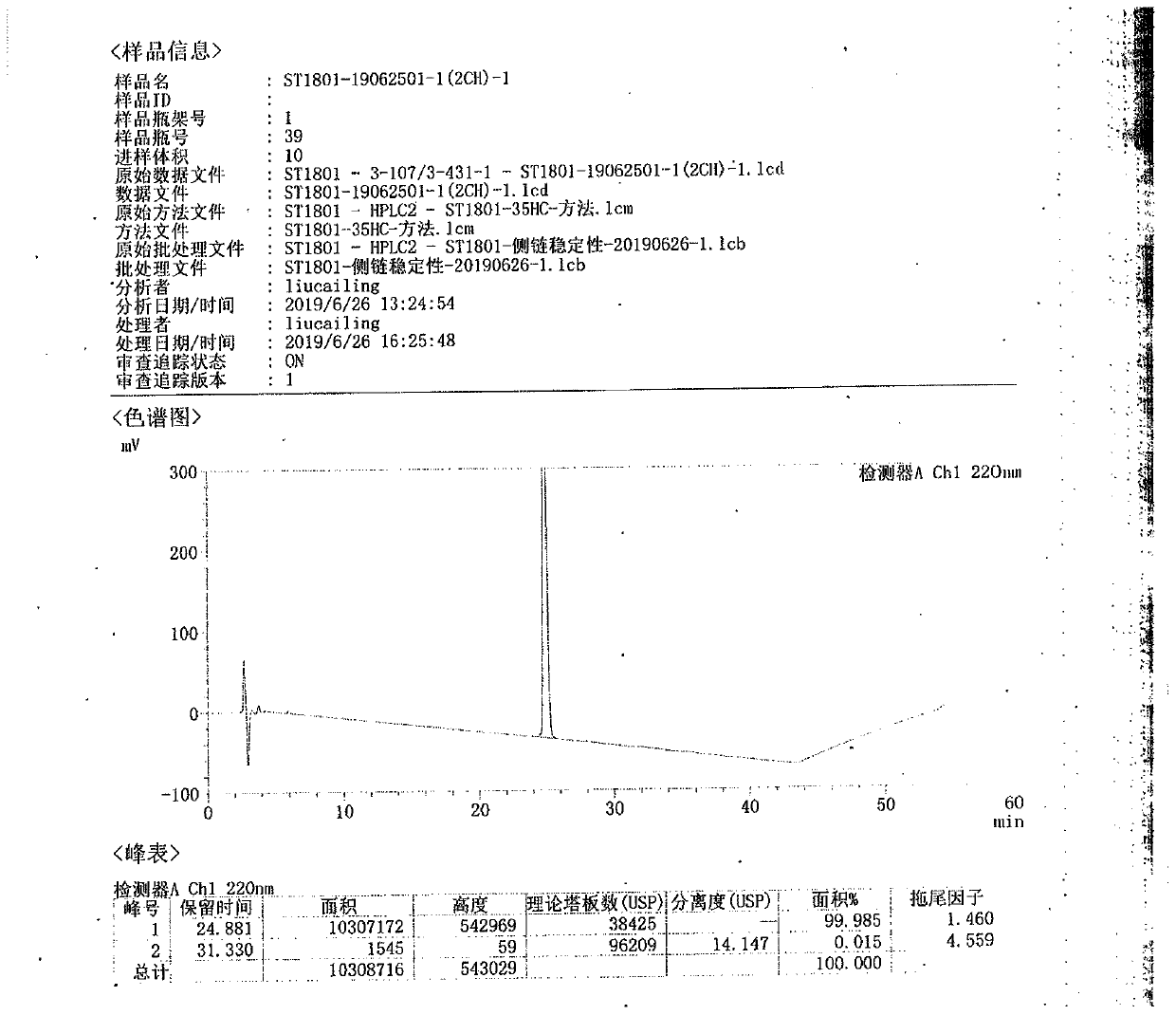

[0078] The pure product of semaglutide obtained by the same purification method in Example 1 is as follows: image 3 As shown, the purity is 99.985%, and 1.07 g of pure semaglutide is obtained after purification of 2 g of crude semaglutide, with a yield of 53.60%.

[0079] Some abbreviations used in the present invention have the following meanings:

[0080]

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of substitution | aaaaa | aaaaa |

| Degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com