Carbon nanocomposite fiber based multi-stimulus response driver of core-shell structure

A carbon nanocomposite and carbon nanotube composite technology, applied in fiber type, fiber treatment, ion implantation plating, etc., can solve the problems of small output energy, large driver hysteresis effect, low cycle life, etc., and achieve a simple design structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention is described in further detail:

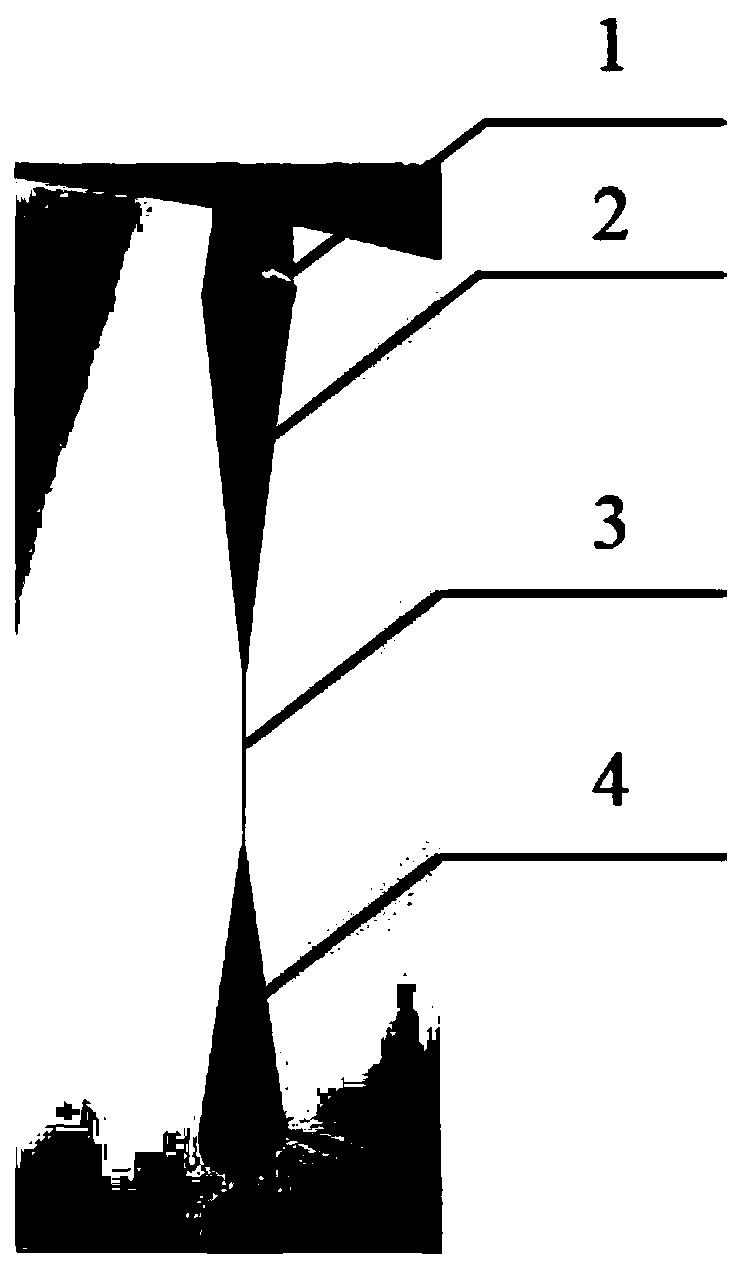

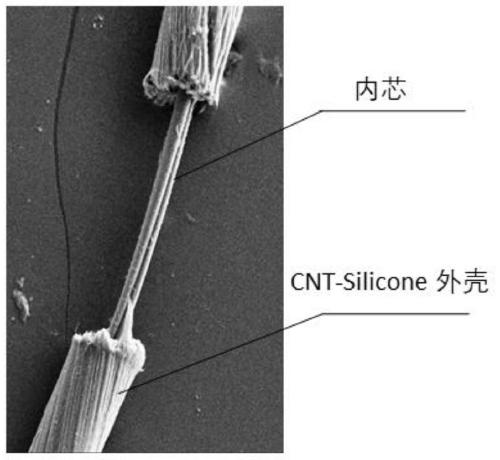

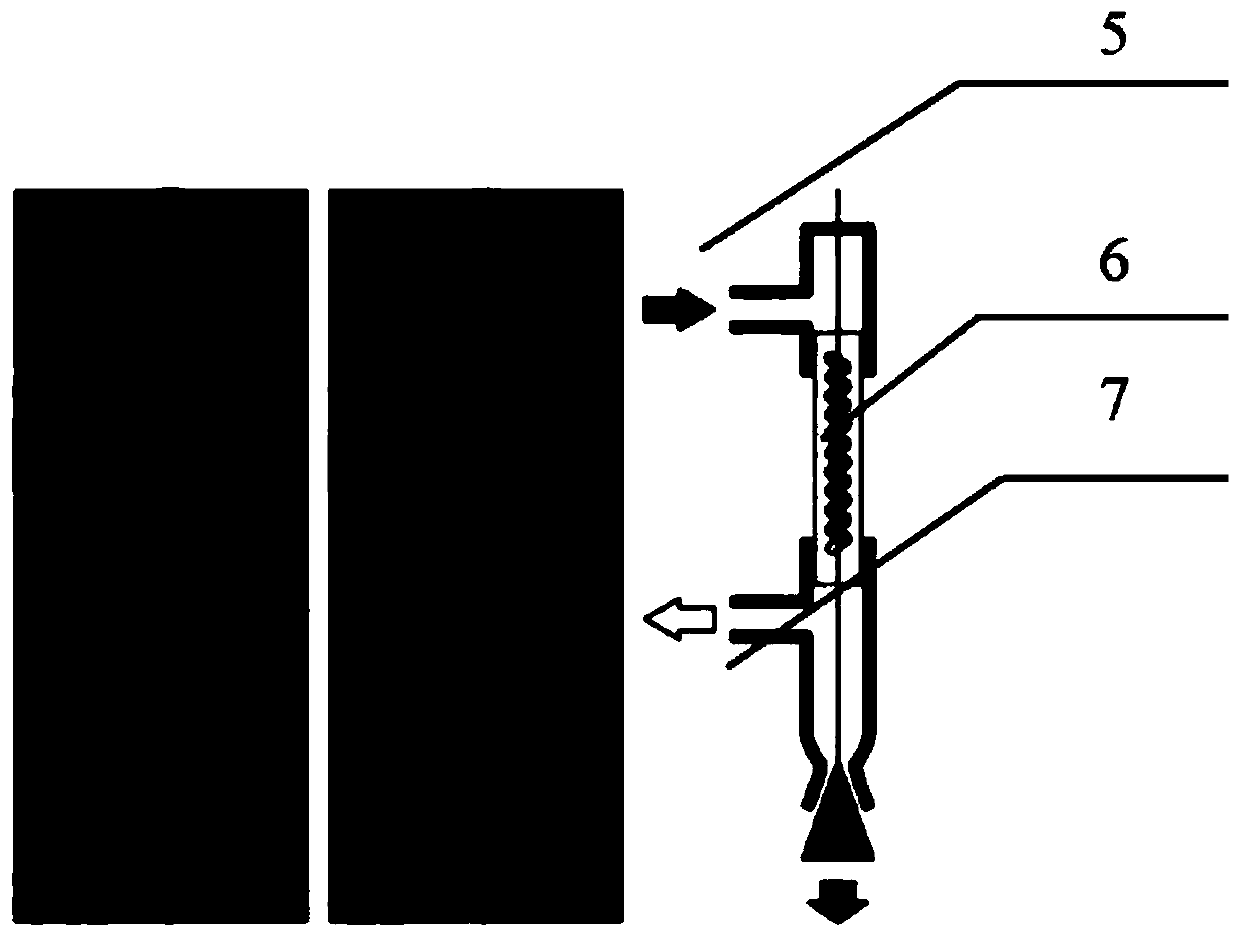

[0038] combine figure 1 and figure 2 , it can be seen that a variety of stimuli-responsive actuators with a core-shell structure based on carbon nanocomposite fibers are characterized in that the various stimuli-responsive actuators are carbon nanotube composite yarns with a conductive helical structure, and the helical The preparation method of the carbon nanotube composite yarn of the structure is as follows: the high-strength organic fiber (such as polyimide, nylon 6,6, etc.) is twisted to form an organic yarn 2 with a certain twist, and the organic yarn 2 As a core, through a concentric mandrel cladding device (such as figure 1 ) winding a carbon nanotube film 4 with a certain twist angle, and infiltrating silicon rubber at the carbon nanotube film 4 as an outer shell to obtain a carbon nanotube composite fiber with a core-shell structure; the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com