Line type large-strain flexible resistance type temperate sensor

A temperature sensor, large strain technology, applied in thermometers, thermometer parts, thermometers using directly heat-sensitive electrical/magnetic components, etc. and other problems, to achieve the effect of slowing down oxidation, large deformation ability, and large resistance to external force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

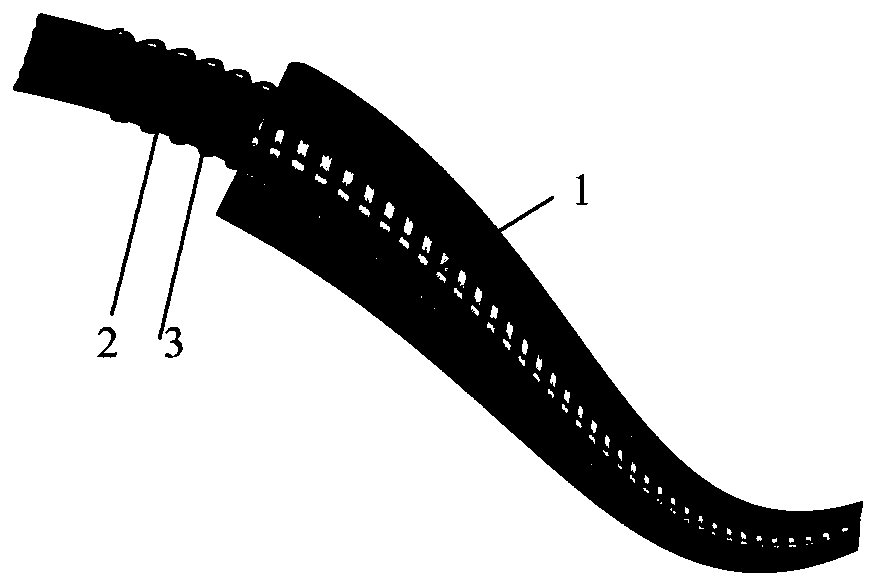

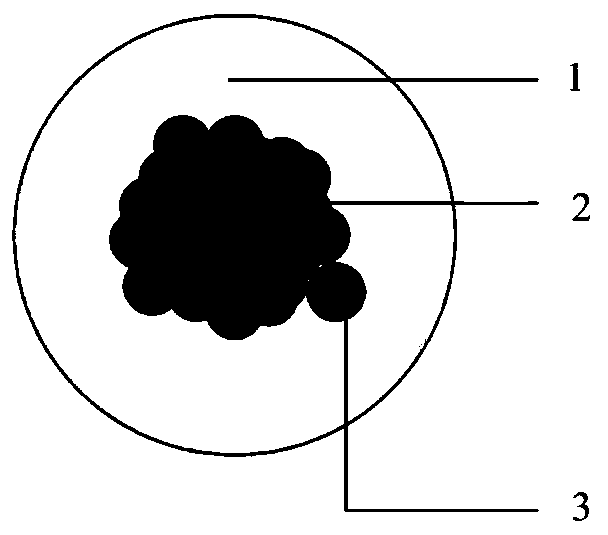

[0024] Embodiment 1: PDMS / (Pt / PU) linear large strain flexible temperature sensor

[0025] The cladding layer is PDMS elastomer, and its elongation at break is 140±10(%); the core is Pt fiber helically wrapped on polyurethane (PU) multifilament, and the elongation at break of PU is greater than 450%.

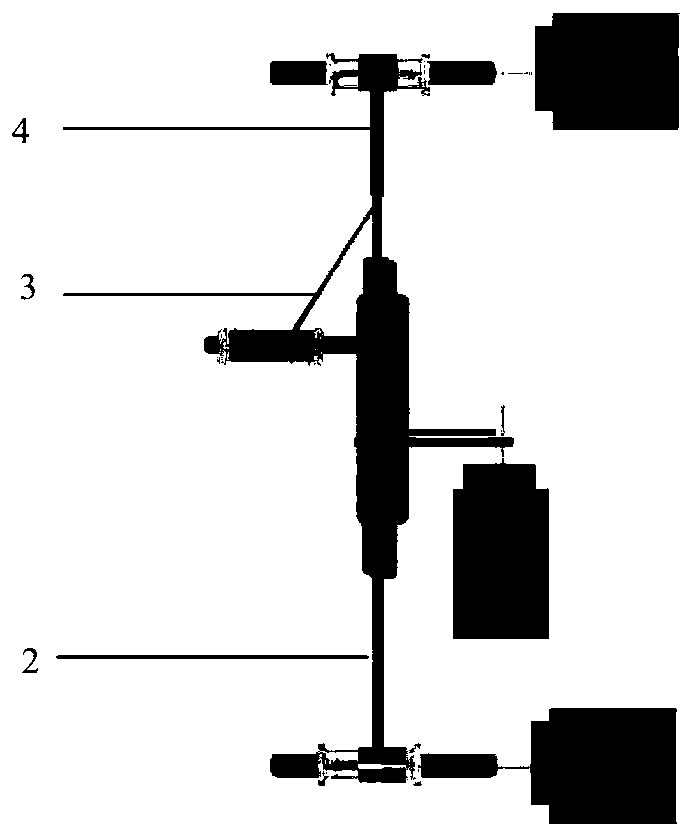

[0026] (1) Core spinning

[0027] The core body is made of Pt fiber as the outer covering yarn and spandex multifilament (PU) as the core yarn. A hollow ingot wrapping machine is used to wrap the Pt fiber on the surface of the spandex yarn with a twist of 1000 twists / m, that is, a pitch of 1 mm. Among them, the diameter of Pt fiber is 20 μm, and the purity is 0.999; the fineness of polyurethane multifilament is 1200D.

[0028] (2) Preparation of PDMS / (Pt / PU) linear large-strain flexible temperature sensor

[0029] Put the above-prepared core yarn into a heat-shrinkable tube with a diameter of 1 mm, inject PDMS into the heat-shrinkable tube with an injection agent (sizing mate...

Embodiment 2

[0030] Embodiment 2: PDMS / (Cu / PU) linear large strain flexible temperature sensor

[0031] (1) Core spinning

[0032] The core body is made of Cu fiber as the outer covering yarn and spandex multifilament (PU) as the core yarn. A hollow ingot wrapping machine is used to wrap the Cu fiber on the surface of the spandex yarn with a twist of 2000 twists / m, that is, a pitch of 0.5 mm. Among them, the diameter of Cu fiber is 300 μm, the purity is 0.999; the fineness of polyurethane multifilament is 1200D.

[0033] (2) Preparation of linear large-strain flexible temperature sensor

[0034] Put the above-prepared core yarn into a heat-shrinkable tube with a diameter of 1 mm, inject PDMS into the heat-shrinkable tube with an injection agent (sizing material: curing agent = 10:1 configuration), place it in an oven, and heat it at 80°C. After 70 minutes of curing, the heat-shrinkable tube shrinks at the same time, and finally the outer heat-shrinkable tube is removed to prepare a PDMS...

Embodiment 3

[0035] Embodiment 3: PU / (Ni / PU) linear large strain flexible temperature sensor

[0036] (1) Core spinning

[0037] The core body is made of Ni fiber as the outer covering yarn and spandex multifilament (PU) as the core yarn. A hollow ingot wrapping machine is used to wrap Ni fibers on the surface of spandex filaments with a twist of 1000 twists / m, that is, a pitch of 1 mm. Among them, the diameter of the Ni metal fiber is 300 μm, and the purity is 0.99; the fineness of the polyurethane multifilament is 840D.

[0038] (2) Preparation of PU / (Ni / PU) linear large-strain flexible temperature sensor

[0039] First shrink the heat-shrinkable tube, put the above-prepared core yarn into the shrinkable heat-shrinkable tube with a diameter of 1 mm, inject polyurethane resin into the heat-shrinkable tube with an injection, and cure it for 1 hour under natural conditions, and finally put the outer layer into the heat-shrinkable tube. The PU / (Ni / PU) linear large-strain flexible temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com