Device and method for studying droplet evaporation and combustion characteristics in turbulent mode

A technology for the evaporation and combustion characteristics of droplets, which is applied in the field of devices for studying the evaporation and combustion characteristics of droplets in turbulent flow mode. high stability, compact structure, and the effect of avoiding misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

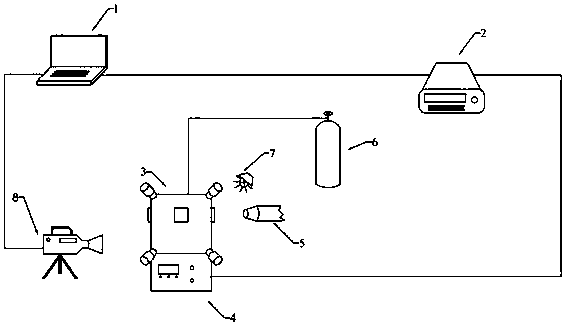

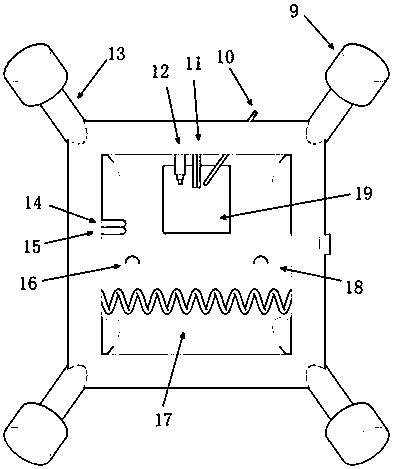

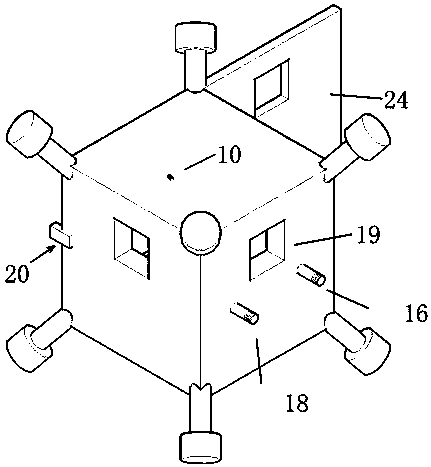

[0035] Such as Figure 1-4As shown, a device for studying the evaporation and combustion characteristics of liquid droplets in turbulent flow mode, including a computer 1, a data acquisition instrument 2, a combustion chamber 3, a temperature controller 4, a high-pressure gas cylinder 6 and a high-speed camera 8, the combustion chamber 3 is a liquid Drop 22 completes the area of evaporation or combustion, and the combustion chamber 3 is connected with the computer 1, the data acquisition instrument 2 and the temperature controller 4, and the internal temperature of the combustion chamber 3 is controlled by the temperature controller 4, and the high-speed camera 8 is connected with the computer 1, and the high-speed camera 8 is responsible for Record the evaporation or combustion process of the droplet 22 and send it to the computer 1. The computer 1 is also connected to the temperature controller 4 and the data acquisition instrument 2. The target temperature, target pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com