An organic waste gas treatment system with good anti-corrosion effect

A technology of organic waste gas and anti-corrosion effect, applied in the direction of separation method, combustion type, lighting and heating equipment, etc., to achieve good anti-corrosion effect, reduce load, and avoid the formation of dioxin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

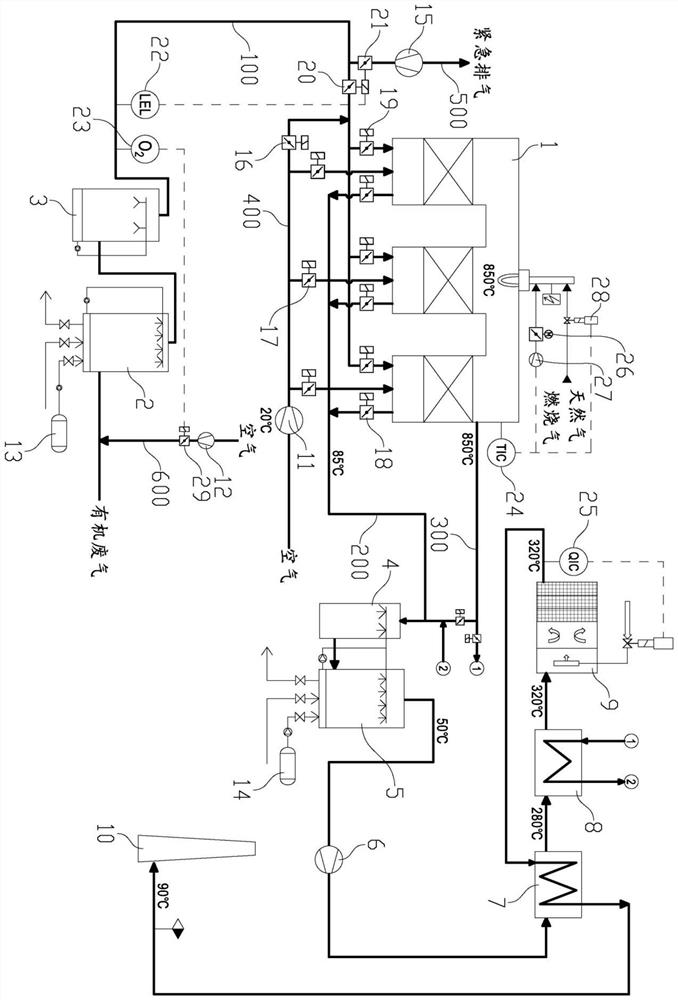

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

[0023] Such as figure 1 As shown, an organic waste gas treatment system with good anti-corrosion effect includes an oxidation furnace 1, the inlet of the oxidation furnace 1 is connected with an exhaust gas path 100, and the gas outlet is connected with a clean gas path 200. The oxidation furnace 1 has three accumulators For the regenerative oxidation furnace in the heat chamber, the inlet of each regenerator is connected to the waste gas path 100 through the waste gas branch at the end of the waste gas path 100, and the gas outlet is connected to the clean gas branch at the head end of the clean gas path 200. The clean gas paths 200 are connected to each other, and each waste gas branch is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com