Chemical for removing nitrogen and/or phosphorus and preparation thereof, and application of chemical to adsorption of wastewater and co-production of slow-release fertilizer

A technology for medicaments and wastewater, applied in application, fertilizer mixture, water/sewage treatment, etc., can solve the problems of frequent regeneration, affecting the use effect, and no secondary pollution, so as to achieve high utilization rate of resources, improve treatment effect, and prepare The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

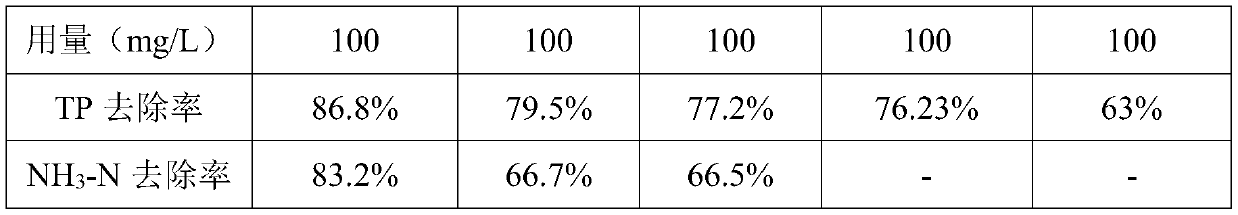

Embodiment 1

[0049] 1) Mix ferrous sulfate and glass pumice according to the mass ratio of 1:25, place them in a ball mill, and grind for 4 hours before use;

[0050] 2) The concentration of ammonia nitrogen in the wastewater is 35mg / L, the concentration of TP is 3.5mg / L, the wastewater in the experiment is 1000mL, and the P / N ratio is 1:1 with 0.15g / LNaH 2 PO 4 Dosing, the ratio of Mg / N substance is 1:1, with 0.15g / L MgCl 2 Mix the two for use;

[0051] 3) Mix the mixture of step 1) and step 2) at a ratio of 15:1, add ammonia water dropwise under ultrasonic conditions at 55°C to make the pH of the solution 8.5, and react for 40 minutes; centrifuge to discard the supernatant, and the solid product is washed Afterwards, it is vacuum-dried to obtain the denitrification and dephosphorization agent.

[0052] 4) Add nitrogen and phosphorus removal agent to the experimental water sample (TP 2.5mg / L, NH 3 -N 35mg / L), adjust the pH to 8, stir and precipitate for 0.5h, the measured TP content i...

Embodiment 2

[0067] 1) Mix ferrous sulfate and glass pumice according to a mass ratio of 1:10, place them in a ball mill, and grind for 4 hours before use;

[0068] 2) The concentration of ammonia nitrogen in the wastewater is 1500mg / L, the concentration of TP is 5mg / L, the wastewater in the experiment is 1000mL, and the P / N ratio is 1:1 with 6.5g / LNaH 2 PO 4 Dosing, the ratio of Mg / N substance is 0.8:1, with 4.0g / L MgCl 2 Mix the two for use;

[0069] 3) Mix the mixture of step 1) and step 2) at a ratio of 15:1, add ammonia water dropwise under ultrasonic conditions at 55°C to make the pH of the solution 8.5, and react for 40 minutes; centrifuge to discard the supernatant, and the solid product is washed Afterwards, it is vacuum-dried to obtain the denitrification and dephosphorization agent.

[0070] 4) Add the denitrification and phosphorus removal agent to the experimental water sample (TP 5mg / L, NH 3 -N 1500mg / L), adjust the pH to 8, stir and precipitate for 0.5h, the measured TP ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com