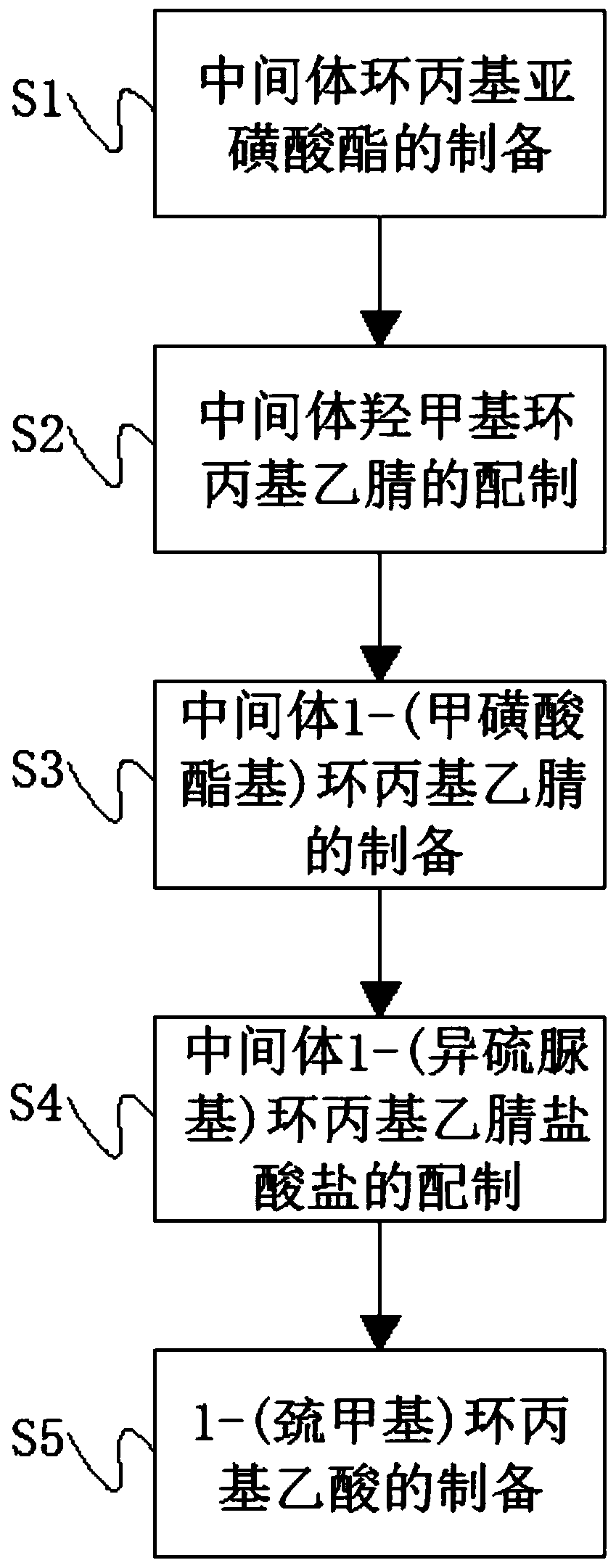

Low-cost, high-yield 1-(mercaptomethyl)cyclopropylacetic acid production process

A technology of hydroxymethylcyclopropylacetonitrile and cyclopropylacetic acid, which is applied in the field of 1-cyclopropylacetic acid production technology, can solve the problems of high production cost, cumbersome separation and purification steps, unsuitable for industrialization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In the low-cost, high-yield 1-(mercaptomethyl)cyclopropylacetic acid production process, each raw material includes by weight: 25 parts of 1,1-cyclopropanedimethanol, 7 parts of sodium cyanide, 4 parts of thiourea 2 parts, 2 parts of triethylamine, 2 parts of dichloromethane, 2 parts of thionyl chloride, 2 parts of anhydrous sodium sulfate, 2 parts of sodium iodide, 2 parts of toluene, 2 parts of absolute ethanol and 2 parts of n-heptane.

[0028] S1. Preparation of intermediate cyclopropyl sulfinate: first add 1,1-cyclopropanedimethanol, triethylamine and dichloromethane in the corresponding weight ratio to a 1000mL flask, cool to 3°C in an ice-salt bath and drop Add thionyl chloride, continue to stir at 3°C for 1-2h after dropping, then wash with 300mL of water, then use anhydrous sodium sulfate to dry and filter, the filtrate is evaporated to dryness in a water bath at 35°C under reduced pressure to obtain a white solid as the middle Cyclopropylsulfinate, the conce...

Embodiment 2

[0034] In the low-cost, high-yield 1-(mercaptomethyl)cyclopropylacetic acid production process, each raw material comprises by weight: 20 parts of 1,1-cyclopropanedimethanol, 5 parts of sodium cyanide, 3 parts of thiourea 1 part, 1 part of triethylamine, 1 part of dichloromethane, 1 part of thionyl chloride, 1 part of anhydrous sodium sulfate, 1 part of sodium iodide, 1 part of toluene, 1 part of absolute ethanol and 1 part of n-heptane.

[0035] S1. Preparation of intermediate cyclopropyl sulfinate: First, add 1,1-cyclopropanedimethanol, triethylamine and dichloromethane in the corresponding weight ratio to a 1000mL flask, cool to 0°C in an ice-salt bath and drop Add thionyl chloride, continue to stir at 0°C for 1 hour after dropping, then wash with 200mL of water, then use anhydrous sodium sulfate to dry and filter, and the filtrate is evaporated to dryness in a water bath at 35°C under reduced pressure to obtain a white solid as the intermediate ring Propyl sulfinate, the c...

Embodiment 3

[0041] In the low-cost, high-yield 1-(mercaptomethyl)cyclopropylacetic acid production process, each raw material includes by weight: 30 parts of 1,1-cyclopropanedimethanol, 10 parts of sodium cyanide, 5 parts of thiourea 3 parts, 3 parts of triethylamine, 3 parts of dichloromethane, 3 parts of thionyl chloride, 3 parts of anhydrous sodium sulfate, 3 parts of sodium iodide, 3 parts of toluene, 3 parts of absolute ethanol and 3 parts of n-heptane.

[0042] S1. Preparation of intermediate cyclopropyl sulfinate: first add 1,1-cyclopropanedimethanol, triethylamine and dichloromethane in corresponding weight ratios to a 1000mL flask, cool to 5°C in an ice-salt bath and drop Add thionyl chloride, continue to stir at 5°C for 2 hours after dropping, then wash with 400mL of water, then use anhydrous sodium sulfate to dry and filter, and the filtrate is evaporated to dryness in a water bath at 35°C under reduced pressure to obtain a white solid as the intermediate ring Propyl sulfinate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com