Liquid metal based flexible resistance micro heater

A liquid metal and micro-heater technology, applied in the direction of heating element materials, etc., can solve the problems that the heater cannot continuously provide heat, and the working temperature of the electrode of the flexible resistance micro-heater is limited, so as to improve the working temperature range and service life , Improve flexibility, ease of processing and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

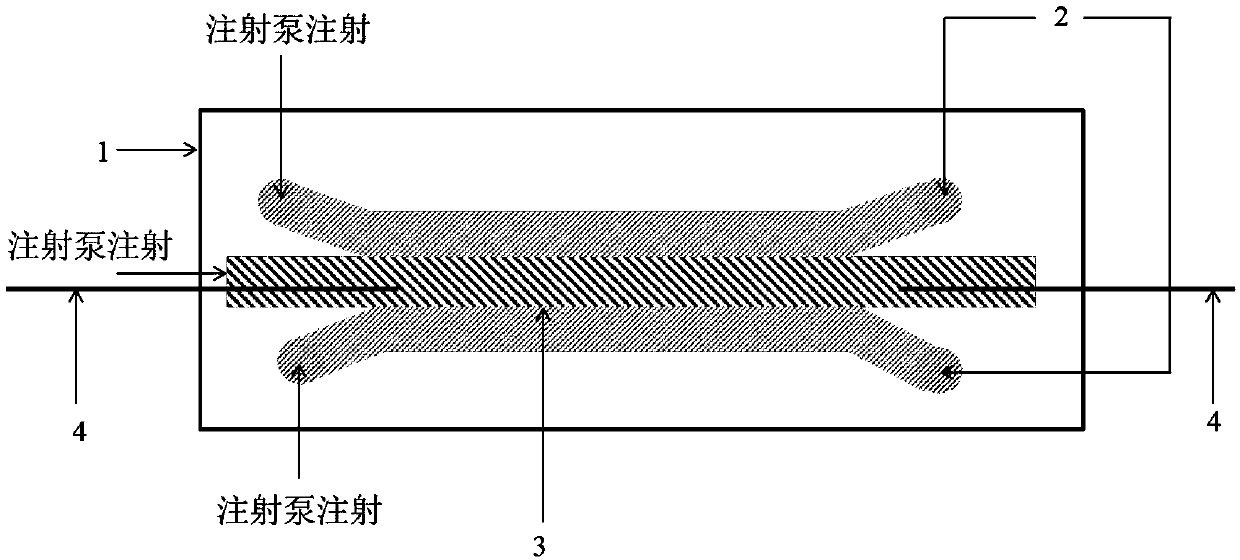

[0033] see figure 1 , a flexible resistance micro-heater, including a housing 1 made of PDMS, a liquid metal resistor, and a lead wire 4. The length and width of the housing 1 are 2cm×1cm, and the upper surface of the housing is provided with a heating device for carrying an object to be heated. area, a liquid metal resistance flow channel is set in the shell, and the liquid metal resistance flow channel is filled with composite liquid metal.

[0034] figure 1 It is a structural schematic diagram of a top view angle. In this embodiment, the liquid metal resistance is composed of three metal segments, one segment of liquid metal at normal temperature and two segments of solid metal at normal temperature. The two sides are solid metal 2 at normal temperature (bismuth-based alloy, Bi 32.5 In 51 sn 16 .5, the melting point is 60 degrees Celsius), and the middle is liquid metal 3 at room temperature (gallium-based alloy, Ga 62 In 25 sn 13 Melting point is 11 degrees Celsius)....

Embodiment 2

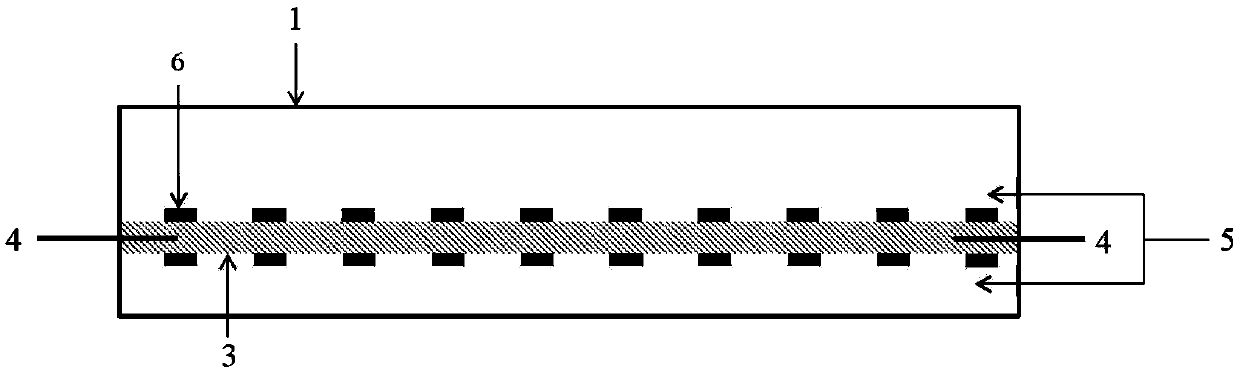

[0039] see figure 2 , a kind of flexible resistance microheater, comprises the microcolumn 6 that shell 1, PDMS are made by PDMS (the length, width and height of a single microcolumn are 30 micrometers, 50 micrometers, 100 micrometers, between microcolumn and microcolumn The distance between them is 30 microns) The liquid metal resistance is a single type of liquid metal at room temperature 3 (Ga 62 In 25 sn 13 Melting point is 11 degrees centigrade) and lead wire 4, air runner 5. The length and width of the housing 1 are 2cm×1cm, and the upper surface of the housing is provided with a heating area for carrying the object to be heated, and the housing is filled with the single liquid metal. The housing 1 is provided with a liquid metal resistance flow channel and an air flow channel, the liquid metal resistance is filled in the liquid metal resistance flow channel, and a plurality of microcolumns are arranged between the liquid metal resistance flow channel and the air flo...

Embodiment 3

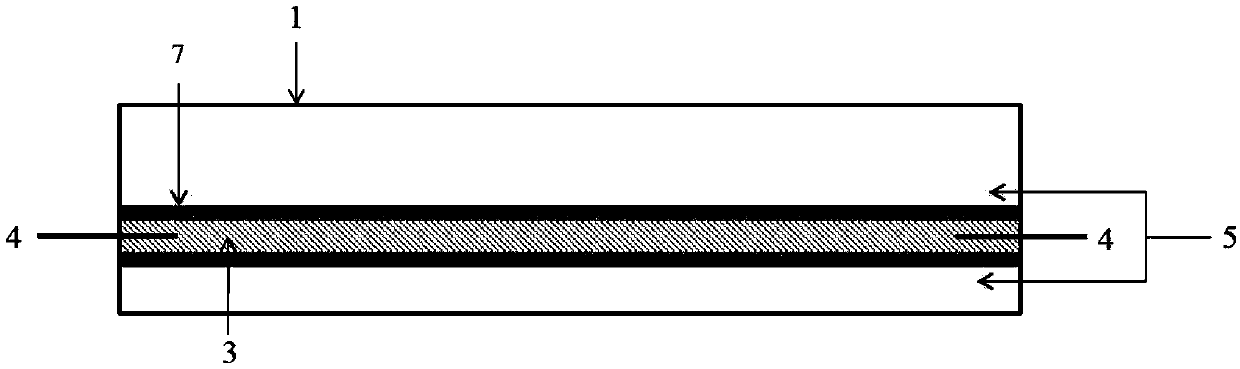

[0043] see image 3 , based on the similar beneficial effects of Example 2, this case proposes a method for directly connecting the air flow channel 5 and the single liquid metal electrode flow channel 3 without micro-pillars. image 3 It is a schematic diagram of the structure with a soluble film 7 from a top view. The air flow channel and the liquid metal flow channel are separated by a layer of soluble film 7 (such as a PDMS template, starch film), and the liquid metal is injected into the electrode flow channel. The soluble film is dissolved away with a solvent (such as toluene, acetone, etc.). Finally, a structure in which the liquid metal flow channel is directly connected to the air flow channel is formed. Due to the high surface tension of the liquid metal, the liquid metal remains in the area of the liquid metal resistance flow channel after the soluble film 7 is removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com