Nitrogen and iron doped conjugated microporous carbon material, and preparation method and application thereof

A technology of conjugated micropores and iron doping, which is applied in the field of preparation of doped porous materials, can solve the problems of lack of resources, expensive platinum group metals, and restrictions on the development of fuel cells, and achieve the effect of long life and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

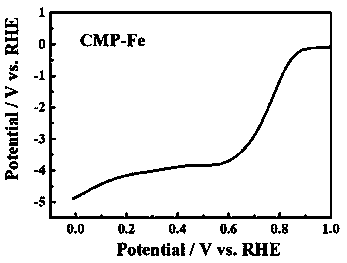

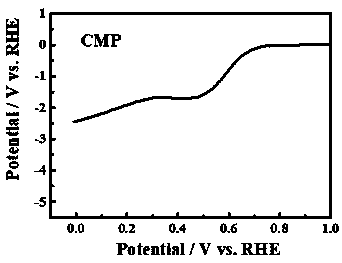

Image

Examples

specific Embodiment 1

[0021] A preparation method of nitrogen, iron doped conjugated microporous carbon material, comprising the following steps:

[0022] (1) In an argon-protected glove box, add 1mmol of 1,3,5-triethynylbenzene and 0.5mmol of 3,6-dibromocarbazole into a 100mL round bottom flask, and then add 0.04mmol of Tetraphenylphosphine palladium and 0.08mmol of cuprous iodide are used as catalysts, then add 4.5mL of DMF and 4.5mL of anhydrous triethylamine to the flask successively with a pipette, stir to make the reactant fully dissolve, and then The glove box was heated up to 80°C, and the mixed solution 7 in the round-bottomed flask was constantly stirred to make it fully react. After 78 hours, the round-bottomed flask was taken out from the glove box, and the resulting solid precipitate was taken out from the round-bottomed flask. After washing with methanol in sequence, suction filtration several times, and Soxhlet extraction with methanol for 16 hours to remove impurities in the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com