Preparation method of (s)-3-hydroxytetrahydrofuran

A technology of hydroxytetrahydrofuran and hydroxyl, which is applied in the field of preparation of -3-hydroxytetrahydrofuran, can solve the problems of unsatisfactory large-scale production, expensive biological enzymes, long reaction cycle, etc., and achieve low production cost, short reaction route and environmental pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

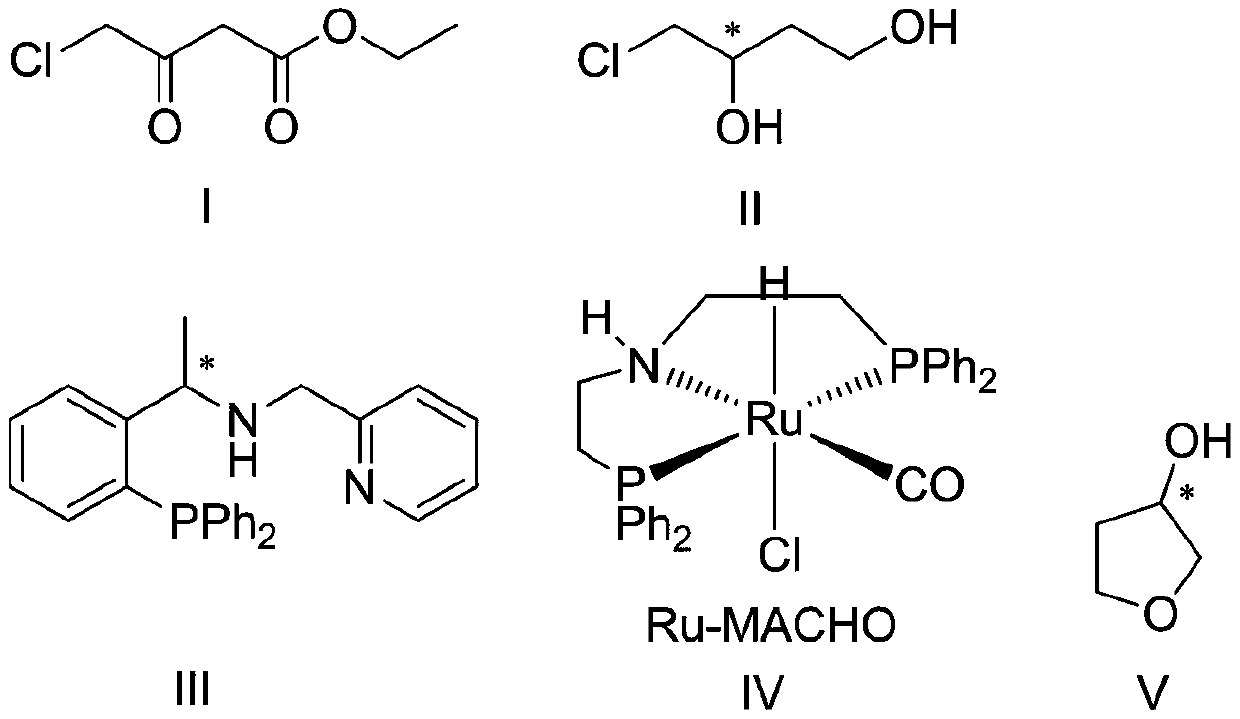

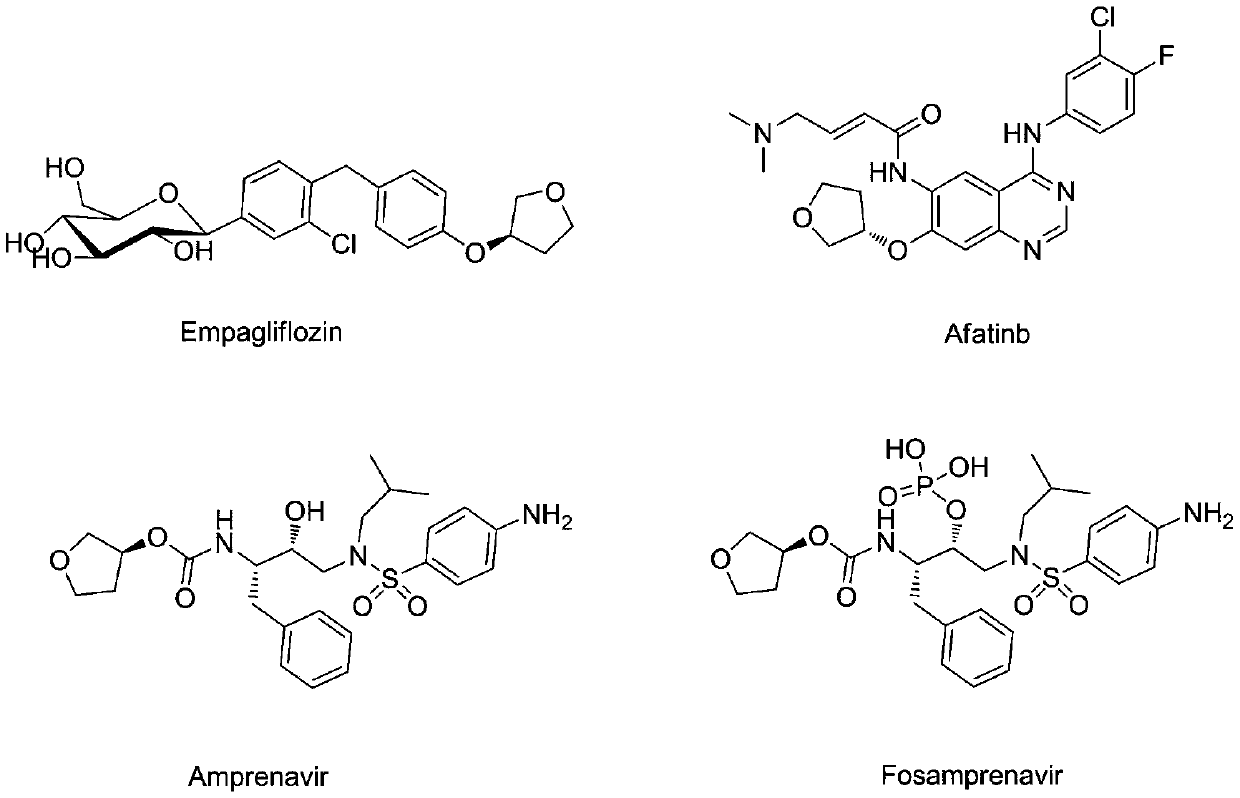

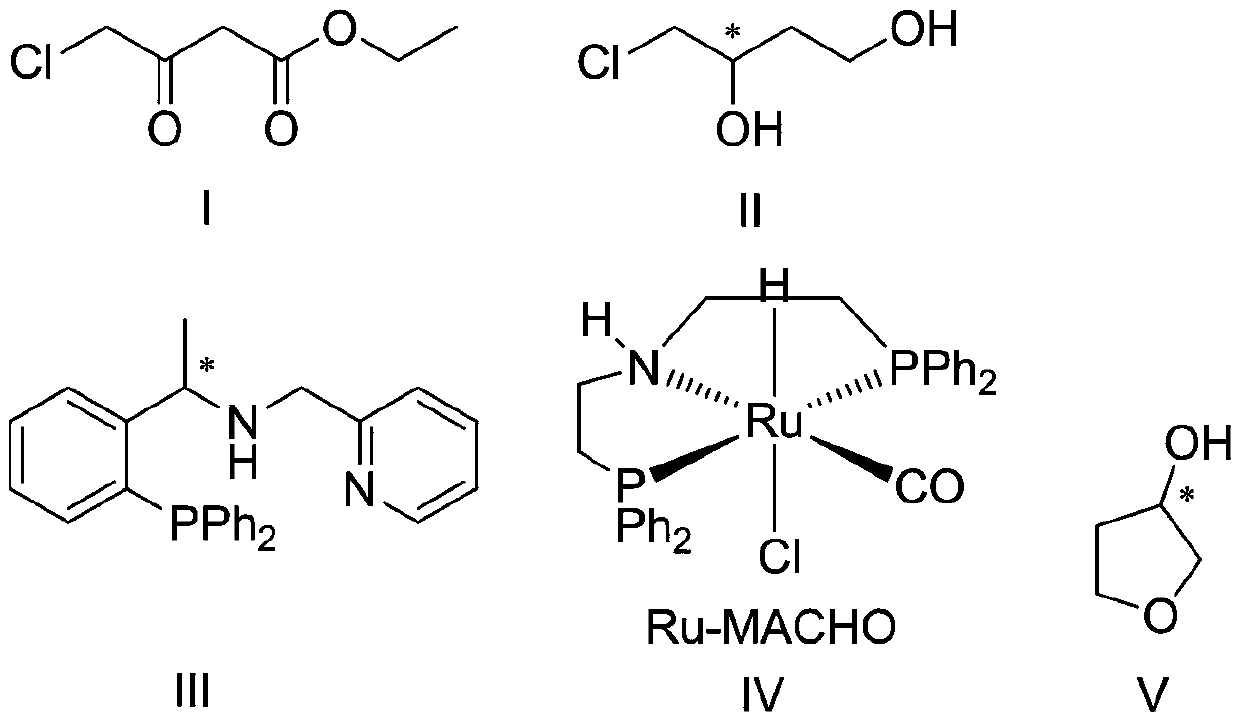

Image

Examples

Embodiment 1

[0033] Step 1, preparation of (s)-4-chloro-3 hydroxy-1-butanol:

[0034] Step 1-1, under nitrogen protection, [Ir(COD)Cl] 2 1. The chiral phosphine-pyridine ligand was dissolved in ethanol and stirred at room temperature for 10 minutes to prepare the first catalyst.

[0035]Step 1-2, according to the amount of substance of the first catalyst theoretically prepared in step 1-1, according to the ratio of the amount of substance of the first catalyst and the amount of substance of ethyl 4-chloroacetoacetate to 1:3000, The substrate 4-chloroacetoacetate was dissolved in ethanol. Wherein, the volume ratio of the total volume of the ethanol used in step 1-1 and the ethanol used in step 1-2 to the substrate ethyl 4-chloroacetoacetate is 3:1. Then, the above ethanol solution of ethyl 4-chloroacetoacetate was added to the first catalyst prepared in step 1-1.

[0036] Step 1-3, according to the molar ratio of potassium tert-butoxide and ethyl 4-chloroacetoacetate is 1:15, the molar r...

Embodiment 2

[0040] Step 1, preparation of (s)-4-chloro-3 hydroxy-1-butanol:

[0041] Step 1-1, under nitrogen protection, [Ir(COD)Cl] 2 1. The chiral phosphine-pyridine ligand was dissolved in methanol and stirred at room temperature for 10 minutes to prepare the first catalyst.

[0042] Step 1-2, according to the amount of substance of the first catalyst theoretically prepared in step 1-1, according to the ratio of 1:2000 of the amount of substance of the first catalyst and the amount of substance of ethyl 4-chloroacetoacetate, The substrate 4-chloroacetoacetate was dissolved in methanol. Wherein, the volume ratio of the total volume of the methanol used in step 1-1 and the methanol used in step 1-2 to the substrate ethyl 4-chloroacetoacetate is 5:1. Then, the above methanol solution of ethyl 4-chloroacetoacetate was added to the first catalyst prepared in step 1-1.

[0043] Step 1-3, according to the molar ratio of sodium methylate and ethyl 4-chloroacetoacetate is 1:20, the molar ra...

Embodiment 3

[0047] Step 1, preparation of (s)-4-chloro-3 hydroxy-1-butanol:

[0048] Step 1-1, under nitrogen protection, [Ir(COD)Cl] 2 1. The chiral phosphine-pyridine ligand was dissolved in anhydrous dichloromethane and stirred at room temperature for 10 minutes to prepare the first catalyst.

[0049] Step 1-2, according to the amount of substance of the first catalyst theoretically prepared in step 1-1, according to the ratio of the amount of substance of the first catalyst and the amount of substance of ethyl 4-chloroacetoacetate to 1:5000, The substrate, ethyl 4-chloroacetoacetate, was dissolved in anhydrous dichloromethane. Wherein, the volume ratio of the total volume of the anhydrous dichloromethane used in step 1-1 and the anhydrous dichloromethane used in step 1-2 to the substrate ethyl 4-chloroacetoacetate is 2:1. Then, the above-mentioned ethyl 4-chloroacetoacetate solution in anhydrous dichloromethane was added to the first catalyst prepared in step 1-1.

[0050] Step 1-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com