Directional porous structure and preparation method thereof

A technology of porous structure and directional crystallization, which is applied in the field of directional porous structure and its preparation, can solve the problems of large energy loss, etc., and achieve the effect of small vacuum degree, regular directional porous structure and regular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of oriented porous structure, its preparation method is as follows:

[0041] 1) Take 9g of tert-butanol (freezing point is 25.6°C), 1g of polyvinylpyrrolidone, heat and stir in a water bath at 50°C to dissolve, and make a polymer solution (10wt% polyvinylpyrrolidone);

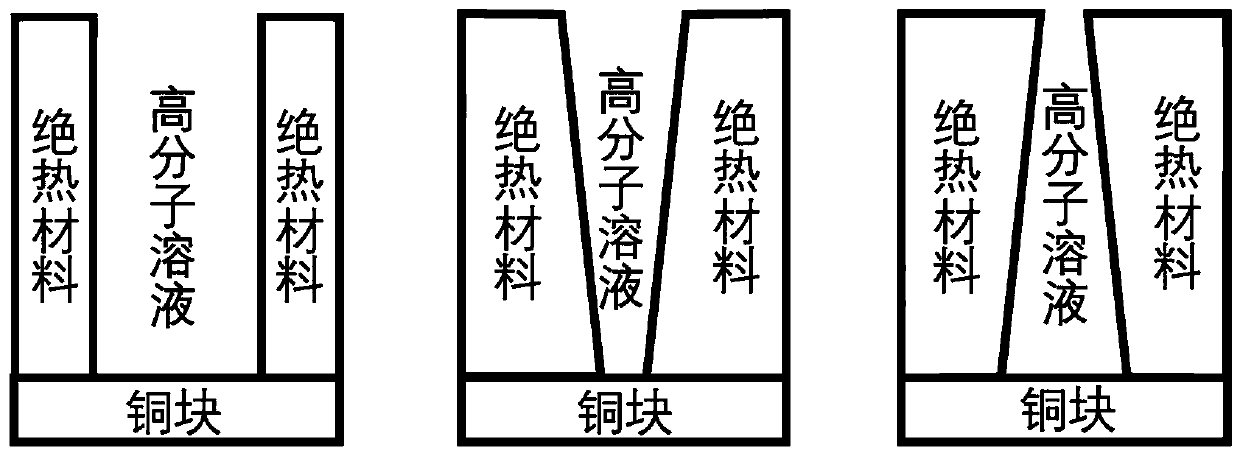

[0042] 2) Pour the fully dissolved polymer solution into the mold (for example figure 1 shown), placed in a room temperature environment for 12h directional crystallization solidification;

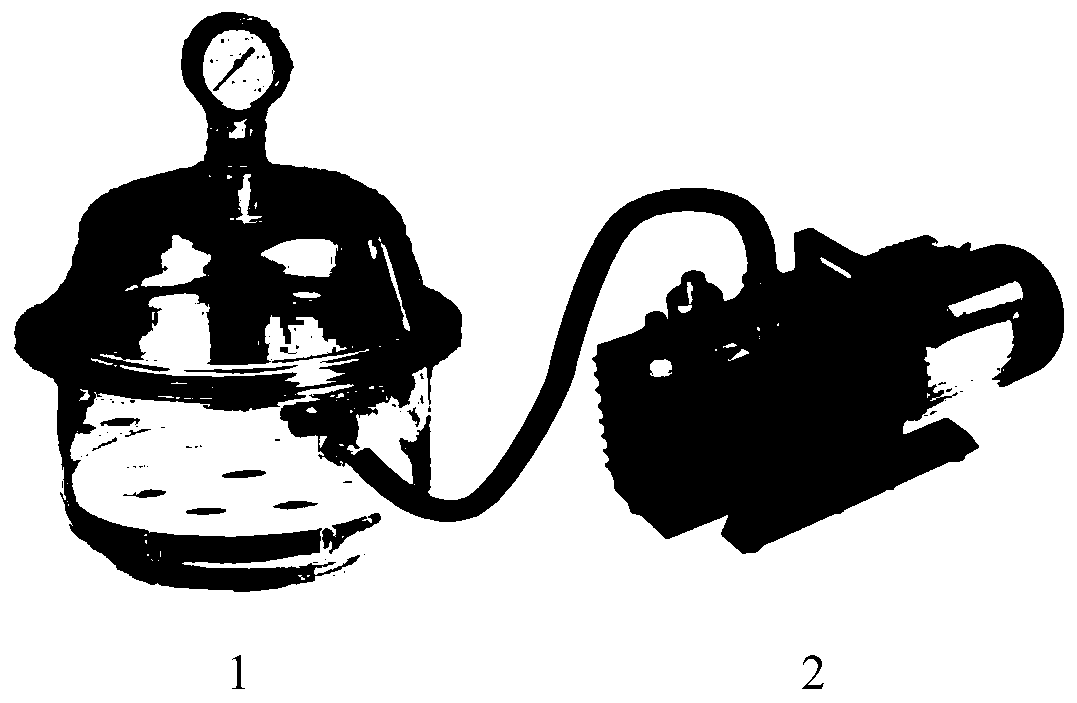

[0043] 3) After being completely solidified, put it into a vacuum desiccator together with the mold (such as figure 2 shown), vacuumize to 0.05mbar, and maintain for 24h to sublimate the organic solvent, and then the polymer oriented porous material can be prepared.

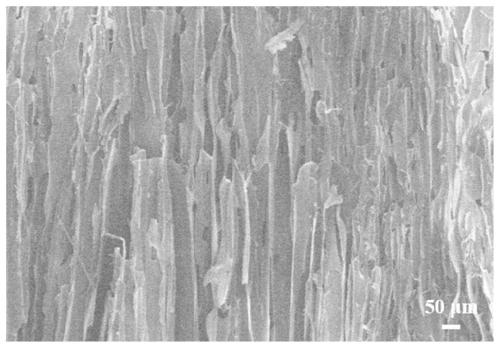

[0044] The side scanning electron microscope picture of the directed porous structure pyrrolidone prepared in this embodiment is shown in image 3 , it can be seen that it has directional channels; Figure 4 , it can be seen that it has a po...

Embodiment 2

[0046] An oriented porous structure, its preparation method differs from that of Example 1 only in that: take 8.5 g of tert-butanol (freezing point is 25.6° C.) and 1.5 g of polyvinylpyrrolidone to make a polymer solution (15 wt % polyvinylpyrrolidone).

[0047] The side scanning electron microscope picture of the directed porous structure pyrrolidone prepared in this embodiment is shown in Figure 5 , it can be seen that it has directional channels; Figure 6 , it can be seen that it has a porous structure with a pore size of ~20 μm.

Embodiment 3

[0049] An oriented porous structure, its preparation method differs from that of Example 1 only in that: take 8.3 g of tert-butanol (freezing point is 25.6° C.) and 1.7 g of polyvinylpyrrolidone to make a polymer solution (17 wt % polyvinylpyrrolidone).

[0050] The side scanning electron microscope picture of the directed porous structure pyrrolidone prepared in this embodiment is shown in Figure 7 , it can be seen that it has directional channels; Figure 8 , it can be seen that it has a porous structure with a pore size of 10-15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap