Preparation method of fatigue-resistant rubber

A technology of anti-fatigue rubber and trans isoprene rubber, which is applied in the field of rubber, can solve the problems of increasing the service life of automobile suspension rubber, not being able to effectively play the role of suspension shock absorption, and permanent deformation of shock absorption suspension, etc., to achieve high Good physical properties and plasticity, good wear resistance and fatigue resistance, and low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

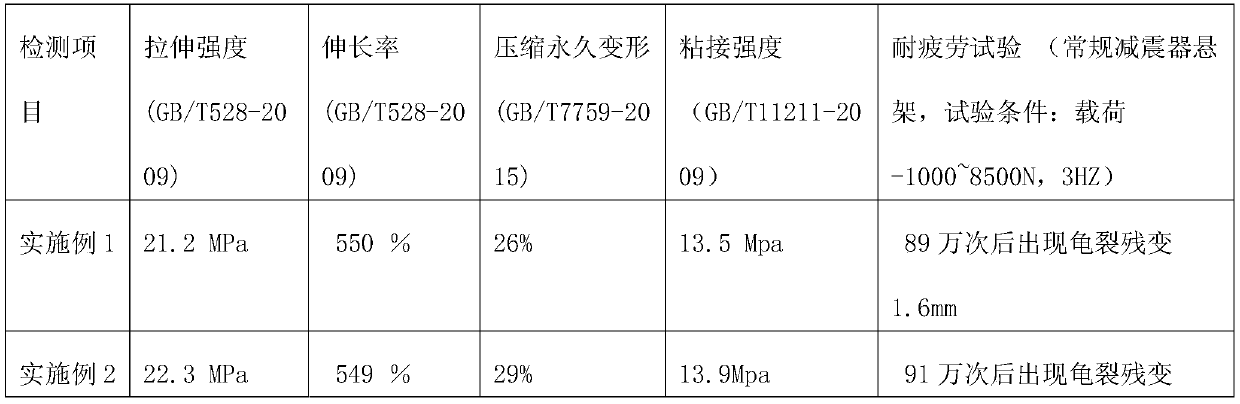

Embodiment 1

[0031] A preparation method for fatigue-resistant rubber, comprising the steps of:

[0032] (1) Material preparation: According to the formula requirements, weigh in parts by weight: 80 parts of natural rubber, 10 parts of trans isoprene rubber, 10 parts of butadiene rubber, 5 parts of zinc oxide by indirect method, 2 parts of stearic acid, micro 2 parts of crystal wax, 2 parts of anti-aging agent RD, 5 parts of resin, 30 parts of carbon black, 10 parts of aromatic oil, 1 part of accelerator DM, 1 part of sulfur, spare;

[0033] (2) One-stage plastication: put natural rubber, butadiene rubber BR9000, and trans isoprene rubber into the feeding chamber through the feeding port and pass it into the mixing chamber, open the external temperature control cooling device to control the temperature: 90°C, and then adjust In the internal mixer, the rotor speed of the internal mixing chamber reaches 20rpm, and the top bolt is pressurized to 10MPa to start masticating, and the plasticizin...

Embodiment 2

[0038] A preparation method for fatigue-resistant rubber, comprising the steps of:

[0039] (1) Material preparation: According to the formula requirements, weigh in parts by weight: 60 parts of natural rubber, 30 parts of trans isoprene rubber, 10 parts of butadiene rubber, 4 parts of aluminum oxide, 4 parts of magnesium oxide, 2 parts of stearic acid 5 parts of refined paraffin, 5 parts of anti-aging agent 4010NA, 10 parts of resin, 60 parts of carbon black, 30 parts of 46# engine oil, 3 parts of accelerator CZ, 3 parts of sulfur, spare;

[0040] (2) One-stage plastication: put natural rubber, butadiene rubber BR9000, and trans isoprene rubber into the feeding chamber through the feeding port and pass it into the mixing chamber, open the external temperature control cooling device to control the temperature: 100°C, and then adjust The rotor speed of the internal mixing chamber in the internal mixer reaches 22rpm, and the top bolt is pressurized to 10MPa to start masticating,...

Embodiment 3

[0045] A preparation method for fatigue-resistant rubber, comprising the steps of:

[0046] (1) Material preparation: According to the formula requirements, weigh in parts by weight: 70 parts of natural rubber, 20 parts of trans isoprene rubber, 10 parts of butadiene rubber, 2 parts of zinc oxide by indirect method, 4 parts of magnesium oxide, stearin 2 parts of acid, 3 parts of anti-ozone wax, 2 parts of anti-aging agent RD and 2 parts of anti-aging agent 4010NA, 8 parts of resin, 45 parts of carbon black, 20 parts of paraffin oil, 1 part of accelerator DM and 1 part of accelerator CZ, 2 parts of sulfur, spare;

[0047] (2) One-stage plastication: Put natural rubber, butadiene rubber BR9000, and trans isoprene rubber into the feeding chamber through the feeding port and pass it into the mixing chamber, open the external temperature control cooling device to control the temperature: 95°C, and then adjust In the internal mixer, the rotor speed of the internal mixing chamber re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com