Carbon-based film for inhibiting secondary electron emission and preparation method thereof

A secondary electron emission, carbon-based technology, used in sputtering, ion implantation, vacuum evaporation, etc., can solve the problems of complex application environment, improve surface roughness, reduce secondary electrons Ejection chance, the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

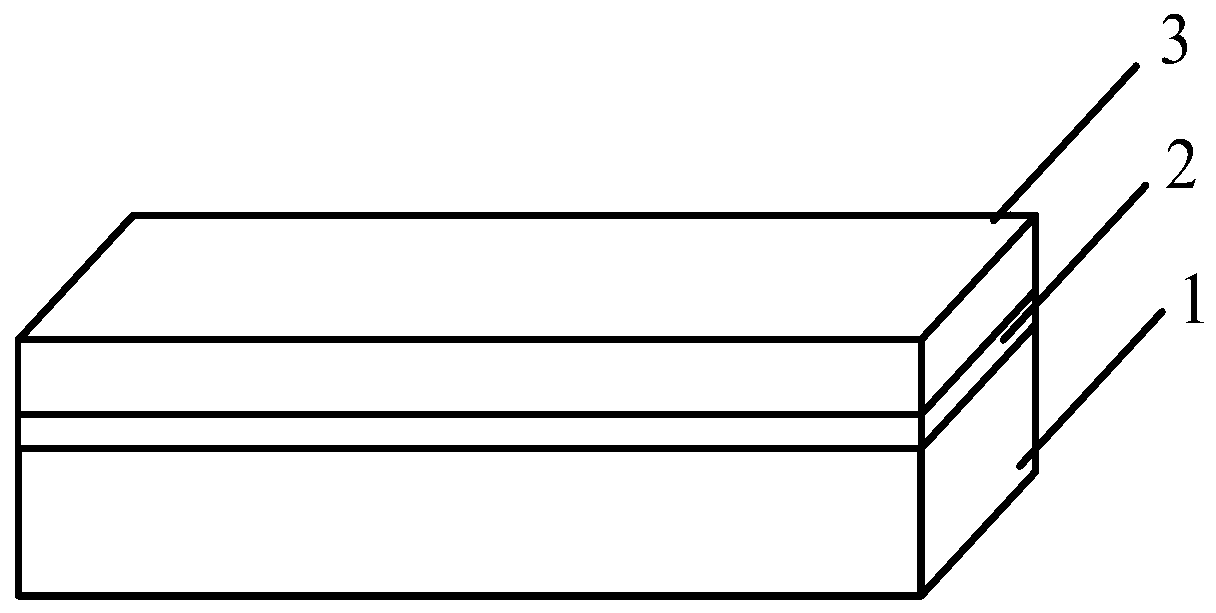

[0023] see figure 1 The carbon-based thin film of the present invention is composed of a titanium buffer layer 2 and an amorphous carbon film layer 3 sequentially arranged on the surface of a substrate 1 from bottom to top. The preparation method specifically includes the following steps:

[0024] 1) The titanium buffer layer 2 is deposited on the substrate 1 by direct current sputtering titanium target method. During the deposition process, the substrate temperature is kept at 400°C, argon gas is introduced into the coating chamber, and the pressure in the coating chamber is 0.1Pa. The thickness of the titanium buffer layer 2 is 12 nm.

[0025] 2) The amorphous carbon film layer 3 is deposited on the titanium buffer layer 2 by using the radio frequency sputtering graphite target method. During the deposition process, the substrate temperature is maintained at 350°C, argon gas is introduced into the coating chamber, and the pressure in the coating chamber is 0.2Pa, the thick...

Embodiment 2

[0027] see figure 1 The carbon-based thin film of the present invention is composed of a titanium buffer layer 2 and an amorphous carbon film layer 3 sequentially arranged on the surface of a substrate 1 from bottom to top. The preparation method specifically includes the following steps:

[0028] 1) The titanium buffer layer 2 is deposited on the substrate 1 by direct current sputtering titanium target. During the deposition process, the substrate temperature is kept at 450°C, argon gas is introduced into the coating chamber, and the pressure in the coating chamber is 0.3Pa. The thickness of the titanium buffer layer 2 is 20 nm.

[0029] 2) The amorphous carbon film layer 3 is deposited on the titanium buffer layer 2 by using the radio frequency sputtering graphite target method. During the deposition process, the substrate temperature is kept at 420°C, argon gas is introduced into the coating chamber, and the pressure in the coating chamber is 0.9Pa, the thickness of the d...

Embodiment 3

[0032] see figure 1 The carbon-based thin film of the present invention is composed of a titanium buffer layer 2 and an amorphous carbon film layer 3 sequentially arranged on the surface of a substrate 1 from bottom to top. The preparation method specifically includes the following steps:

[0033] 1) The titanium buffer layer 2 is deposited on the substrate 1 by direct current sputtering titanium target method. During the deposition process, the substrate temperature is maintained at 500°C, argon gas is introduced into the coating chamber, and the pressure in the coating chamber is 0.5Pa. The thickness of the titanium buffer layer 2 is 30 nm.

[0034]2) The amorphous carbon film layer 3 is deposited on the titanium buffer layer 2 by using the radio frequency sputtering graphite target method. During the deposition process, the substrate temperature is kept at 500°C, argon gas is introduced into the coating chamber, and the pressure in the coating chamber is 0.3Pa, the thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com