Compositions comprising acetic acid and hypochlorous acid and methods for treating biofilm

A composition and technology of hypochlorous acid, applied in the direction of hypochlorous acid, botanical equipment and methods, drug combination, etc., can solve the problems of not being widely available, difficult to use, and unable to effectively attack biofilms for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0174] Embodiment 1: product analysis

[0175] When spectrophotometry is extended to also cover the visible range, color can be detected. The gas usually produced during the generation of HOCl is ClO 2 , Cl 2 O and Cl 2 , all of these gases are detectable in the visible range and appear yellow or yellow-red. Tzanavaras et al., (Central European J. of Chemistry, 2007, 5(1) 1-12). The data in Figure 9 demonstrate that HOCl produced by the method of the present invention exhibits no absorption of colored gases, as indicated by the absence of colored species. It is well known that HOCl produces a peak at 292 nm (Feng et al., 2007, J. Environ. Eng. Sci. 6, 277-284).

Embodiment 2

[0177] HOCl produced by the above method was stored under thermal stress at 40 °C in order to accelerate degradation using four different types of aqueous solutions: (1) reagent grade water (deionized water); (2) tap water; (3) with phosphate buffer reagent grade water; and (4) tap water with phosphate buffer. The properties of the HOCl product were monitored after initial reaction (T=0); 4 weeks (T=4); 8 weeks (T=8); and 12 weeks (T=12).

[0178] Figure 10 is a graph showing the amount (parts per million (ppm)) of HOCl initially produced (T=0) and its stability over time. The data showed that reagent grade water (deionized water) without phosphate buffer was most stable over 12 weeks, showing minimal product degradation compared to initial yield. The product produced using deionized water was much more stable than that produced using tap water. Furthermore, surprisingly, the data showed that phosphate buffer could negatively affect the yield of HOCl product.

[0179] Figur...

Embodiment 3

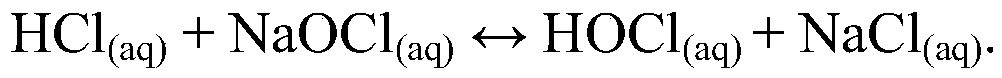

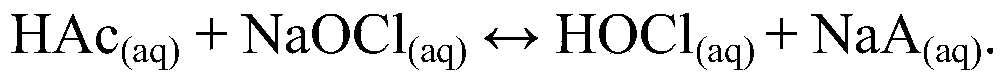

[0181] Embodiment 3: the comparison of acetic acid and hydrochloric acid

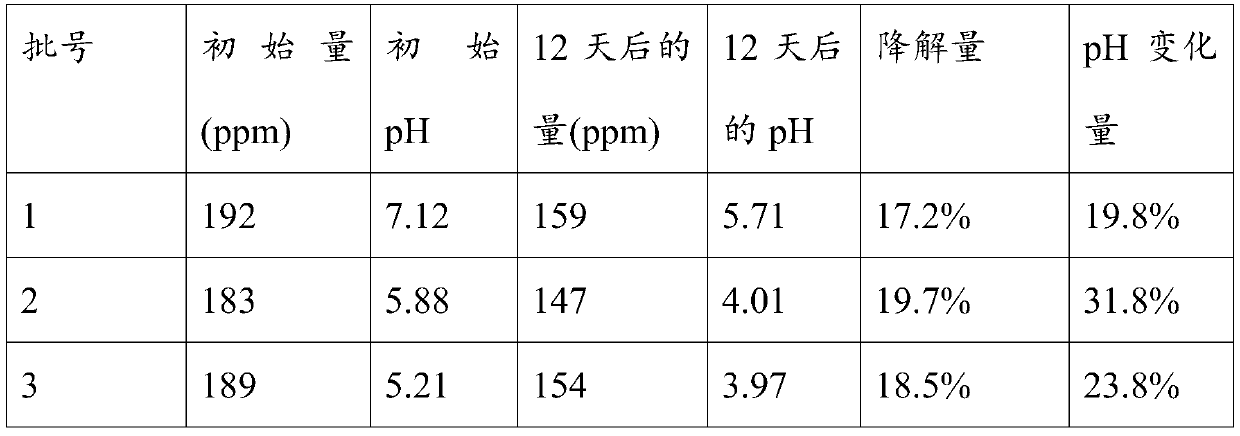

[0182] Using the method described above, hydrochloric acid (HCl) and acetic acid were used to prepare HOCl, which was then stored under thermal stress at 40°C. The amount of HOCl produced initially (T=0) was recorded, followed by the amount of HOCl product remaining after 12 days. Each case produces three batches. The data for HCl to HOCl are shown in Table 1. The data for HOCl produced from acetic acid are shown in Table 2.

[0183] Table 1: HOCl generation with HCl

[0184]

[0185] Table 2: HOCl generation with acetic acid

[0186]

[0187] The data show that use of acetic acid provides greater product stability, most likely due to greater stability of pH. Without being bound by any particular theory or mechanism of action, it is believed that acetic acid has a different protonation ability than hydrochloric acid, ie, acetic acid contributes fewer protons to the liquid than hydrochlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com