Concave Green Space Construction Method Based on Sponge City

A sponge city and construction method technology, applied in the direction of soil preparation methods, botanical equipment and methods, fertilization devices, etc., can solve the problems of low survival rate of grass, difficulty in adapting to grass, difficulty in absorbing nutrients and water, etc., and achieve high survival rate , Promote rapid growth and good fat content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

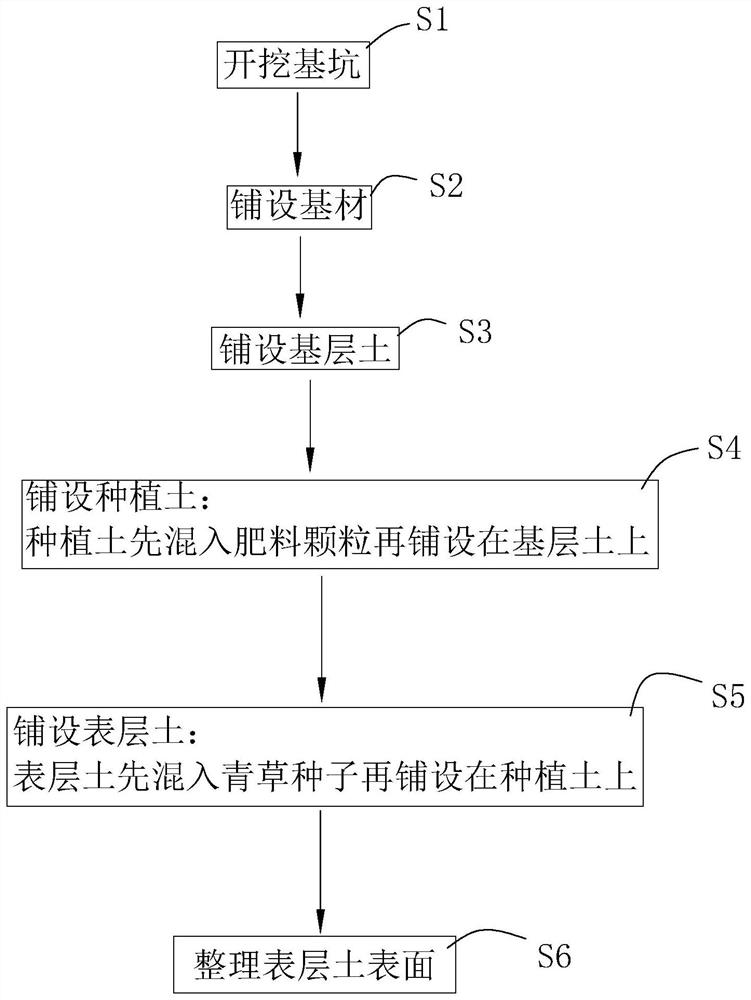

[0059] A concave green space construction method based on sponge city, refer to figure 1 , including the following steps:

[0060] S1. Excavate the foundation pit, as follows:

[0061] The foundation pit is excavated according to the design requirements, and the horizontal section size of the foundation pit is consistent with the horizontal section size of the concave green space in the design.

[0062] S2. Lay the substrate, as follows:

[0063] The bottom of the foundation pit is compacted by a road roller to make the bottom of the foundation pit level, and then permeable bricks are laid to form a support layer. At least two layers of permeable bricks are laid, and the level of the top of the support layer starts from the center of the foundation pit and gradually moves toward the edge of the foundation pit. In addition, in this embodiment, the minimum thickness at the midpoint of the support layer is 30 cm, and the maximum thickness at the edge of the support layer is 50 ...

Embodiment 2

[0079] A preparation method of fertilizer granules, comprising the following steps:

[0080] a. Broken, as follows:

[0081] Put the dry animal feces and activated carbon into the grinder and grind them into powder with a particle size of 0.01-0.1mm.

[0082] b. Mix as follows:

[0083] 100kg of dry animal excrement powder, 8kg of calcium peroxide, 23kg of polyvinyl alcohol, 15kg of activated carbon, and 3kg of pineapple leaf fiber were added to the stirring tank, and the rotating speed was 30r / min, and stirred for 5min to form a mixture;

[0084] The length of the pineapple leaf fibers is 2mm.

[0085] Calcium peroxide adopts nano-calcium peroxide.

[0086] c. Press to make granules, as follows:

[0087] The mixture was punched in a granulator to form spherical granules with a particle size of 5 mm to form fertilizer granules.

[0088] d. Dry, as follows:

[0089] The fertilizer granules were laid flat outside for 30 days to fully dry.

Embodiment 3

[0091] A preparation method of fertilizer granules, comprising the following steps:

[0092] a. Broken, as follows:

[0093] Put the dry animal feces and activated carbon into the grinder and grind them into powder with a particle size of 0.01-0.1mm.

[0094] b. Mix as follows:

[0095] 100kg of dry animal excrement powder, 10kg of calcium peroxide, 25kg of polyvinyl alcohol, 16kg of activated carbon, and 4kg of pineapple leaf fiber were added to the stirring tank, and the rotating speed was 30r / min, and stirred for 5min to form a mixture;

[0096] The length of the pineapple leaf fibers is 2mm.

[0097] Calcium peroxide adopts nano-calcium peroxide.

[0098] c. Press to make granules, as follows:

[0099] The mixture was punched in a granulator to form spherical granules with a particle size of 8 mm to form fertilizer granules.

[0100] d. Dry, as follows:

[0101] The fertilizer granules were laid flat outside for 30 days to fully dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com