A feed addictive, its preparation process and use

A feed additive and production method technology, applied in animal feed, animal feed, application, etc., can solve problems such as uneven quality, unsound standardization system of feed additive industry, and cumbersome use process of biological feed additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

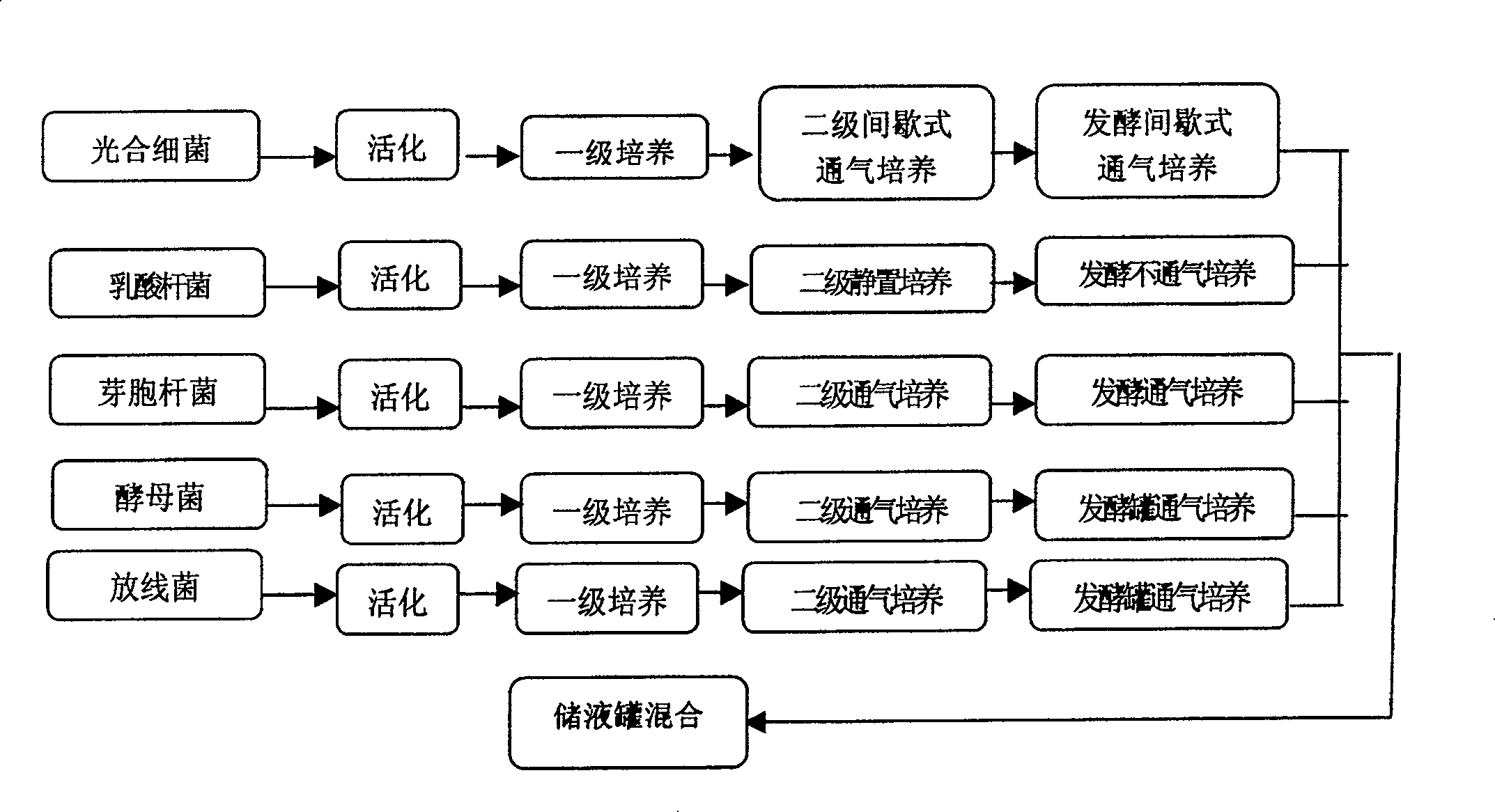

Method used

Image

Examples

Embodiment 1

[0118] The production of each fermentation broth:

[0119] 1. Inoculate the parent species of photosynthetic bacterium Rhodopseudomonas palustris on primary medium (MgSO 4 ·7H 2 O 0.2g, (NH 4 ) 2 SO 4 1.0g, NaHCO 3 5.0g, K 2 HPO 4 0.5g, NaCl 0.2g, peptone 1.5g; each component was dissolved in 400ml distilled water, and washed with H 3 PO 4 and Na 2 CO 3 Adjust the pH to 7.1, then add distilled water to 1000ml, and sterilize at 115°C for 10 minutes. ), cultivated for 7 days at a temperature of 30°C and a light intensity of 3000 lux to obtain a first-grade strain;

[0120] Inoculate the primary bacterial strains on the secondary medium (sodium acetate 3g, NaCl 0.1g, (NH 4 ) 2 SO 4 0.3g, MgSO 4 0.2g, KH 2 PO 3 0.5g, K 2 HPO 3 0.3g, ferric ammonium citrate 7ml, peptone 1.2g, distilled water to 1000ml, with H 3 PO 4 and Na 2 CO 3 Adjust the pH to 7.2. ), add a small amount of glass beads to the culture container before inoculation, and cultivate for 8 d...

Embodiment 2

[0143] The production of each fermentation broth:

[0144] 1. Inoculate the parent species of photosynthetic bacterium Rhodopseudomonas palustris on primary medium (MgSO 4 ·7H 2 O 0.2g, (NH 4 ) 2 SO 4 1.0g, NaHCO 3 5.0g, K 2 HPO 4 0.5g, NaCl 0.2g, peptone 1.5g; each component was dissolved in 400ml distilled water, and washed with H 3 PO 4 and Na 2 CO 3 Adjust the pH to 7.2, then add distilled water to 1000ml, and sterilize at 115°C for 10 minutes. ), cultivated for 7 days at a temperature of 34°C and a light intensity of 3000 lux to obtain a first-class strain;

[0145] Inoculate the primary bacterial strains on the secondary medium (sodium acetate 3g, NaCl 0.1g, (NH 4 ) 2 SO 4 0.3g, MgSO 4 0.2g, KH 2 PO 3 0.5g, K 2 HPO 3 0.3g, ferric ammonium citrate 7ml, peptone 1.2g, distilled water to 1000ml, with H 3 PO 4 and Na 2 CO 3 Adjust the pH to 7.2. ), add a small amount of glass beads to the culture container before inoculation, and cultivate for 10 d...

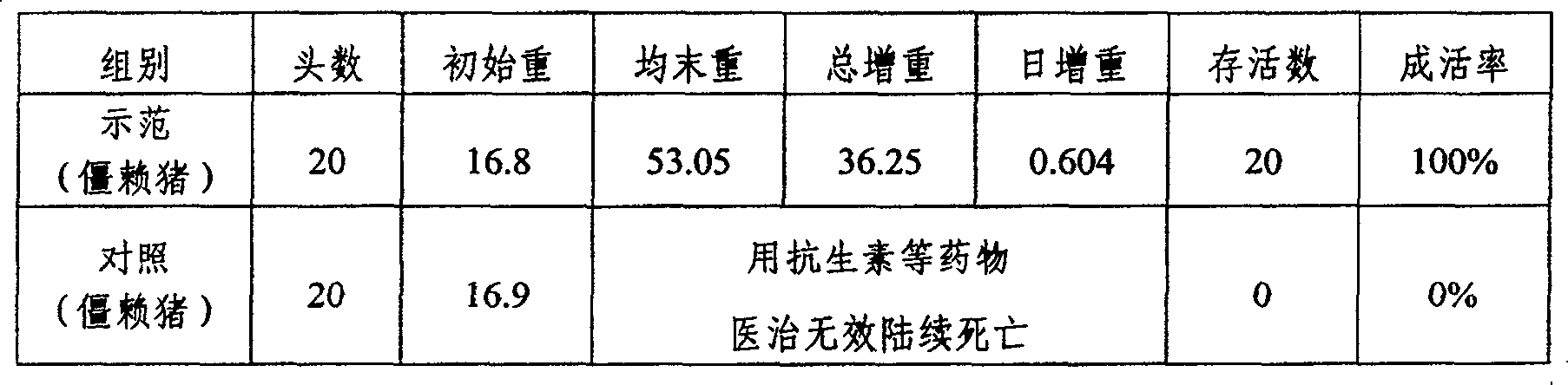

experiment example 1

[0167] Experimental example 1: Feed additive of the present invention improves poultry house environment test

[0168] Table 1 Feed additive of the present invention improves the situation of bad smell Unit: mg / liter

[0169] harmful gas

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com