Meat-flavored seasoning product and preparation method and application thereof

A technology of seasoning and meat flavor, which is applied in the production of dishes and soups. mellow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

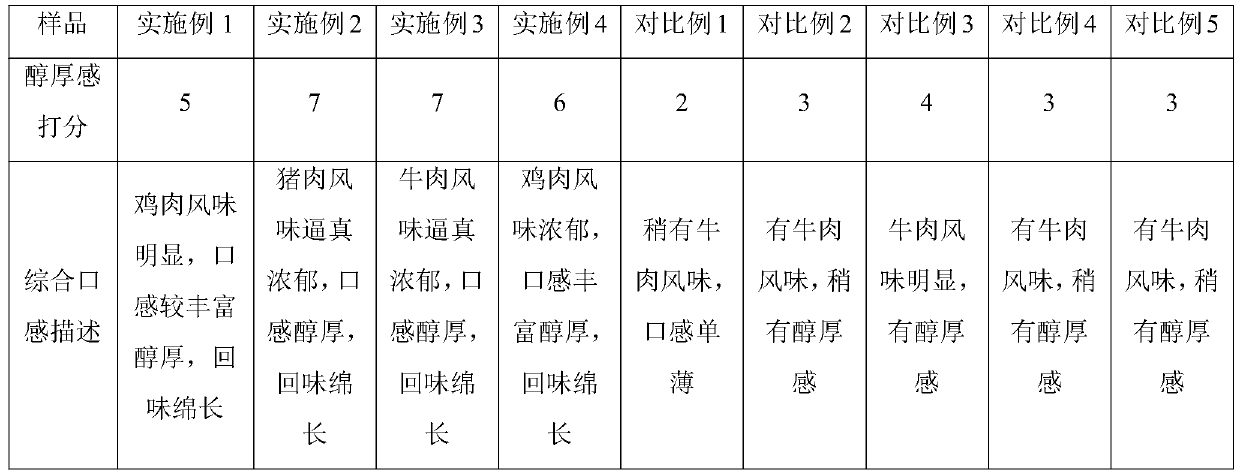

Examples

Embodiment 1

[0033] (1) Take 100 parts by weight of lean chicken meat, add water according to the meat-to-water ratio of 1:1, raise the temperature to 55°C, first add Novozymes compound protease with 0.5% mass of lean chicken meat, and perform enzymatic hydrolysis for 3 hours; then add lean chicken meat 0.3% Novozymes flavor enzyme by mass, hydrolyzed for 3 hours. Then inactivate the enzyme at 85°C for 10 min. After cooling to room temperature, centrifuge at 20,000 r / min for 15 min, take the supernatant, freeze-dry to constant weight, and obtain chicken enzymatic hydrolyzate.

[0034] (2) Weigh chicken enzymatic hydrolyzate 5g, D-xylose 2g, V B1 0.2g, cysteine 0.2g, salt 0.3g, monosodium glutamate 0.05g, amino acid composition 1g, and then add water 20g to obtain a mixture. The molar ratio of glutamic acid, serine, glycine and lysine in the amino acid composition is 1:1:8:1.

[0035] (3) The mixture was reacted for 3 hours under the conditions of pH 6.5 and temperature 120° C. to obta...

Embodiment 2

[0037] (1) Take 200 parts by weight of lean pork meat, add water according to the meat-to-water ratio of 1:2, heat up to 50°C, first add 0.4% compound protease of lean pork meat, and enzymolyze it for 2.5 hours; then add 0.2% of lean pork meat % flavor enzyme, enzymatic hydrolysis for 1h; then inactivate the enzyme at 85°C for 10min. After cooling to room temperature, centrifuge at 20,000 r / min for 15 min, take the supernatant, freeze-dry to constant weight, and obtain pork enzymatic hydrolyzate.

[0038] (2) Weigh pork enzymatic hydrolyzate 2g, D-ribose 1g, cysteine 0.5g, V B1 0.3g, 0.2g of salt, 0.1g of monosodium glutamate, 2g of amino acid composition, and 6g of water were added to obtain a mixture. The molar ratio of glutamic acid, serine, glycine and lysine in the amino acid composition is 1:1:4:2.

[0039] (3) The mixture was reacted for 3.5 hours under the conditions of pH 6 and temperature 110° C. to obtain reaction solution B.

Embodiment 3

[0041] (1) Take 250 parts by weight of lean beef meat, add water according to the meat-to-water ratio of 1:3, heat up to 55°C, first add a compound protease with 0.6% of lean beef mass, and enzymolyze it for 3.5 hours; then add 0.4% beef lean meat mass % flavor enzyme, enzymatic hydrolysis 2h. Then inactivate the enzyme at 85°C for 10 min. After cooling to room temperature, centrifuge at 20,000 r / min for 15 min, take the supernatant, freeze-dry to constant weight, and obtain beef enzymatic hydrolyzate.

[0042] (2) Weigh 1.5g of beef enzymatic hydrolyzate, 2g of arabinose, V B1 0.4g, cysteine 0.4g, salt 0.1g, monosodium glutamate 0.1g, amino acid composition 2g, and then add water 8g to obtain a mixture. The molar ratio of glutamic acid, serine, glycine and lysine in the amino acid composition is 2:1:3:2.

[0043] (3) The mixture was reacted for 4 hours under the conditions of pH 5.5 and temperature 100° C. to obtain reaction solution C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com