A cold heading extrusion composite forming method for non-ferrous metal shell parts for vehicles

A non-ferrous metal and composite forming technology, which is used in the field of cold heading extrusion composite forming of non-ferrous metal shell parts for vehicles, can solve the problems of easy cracking of the lubricating film, improve the surface adhesion, reduce the number of processing steps, and simplify the processing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

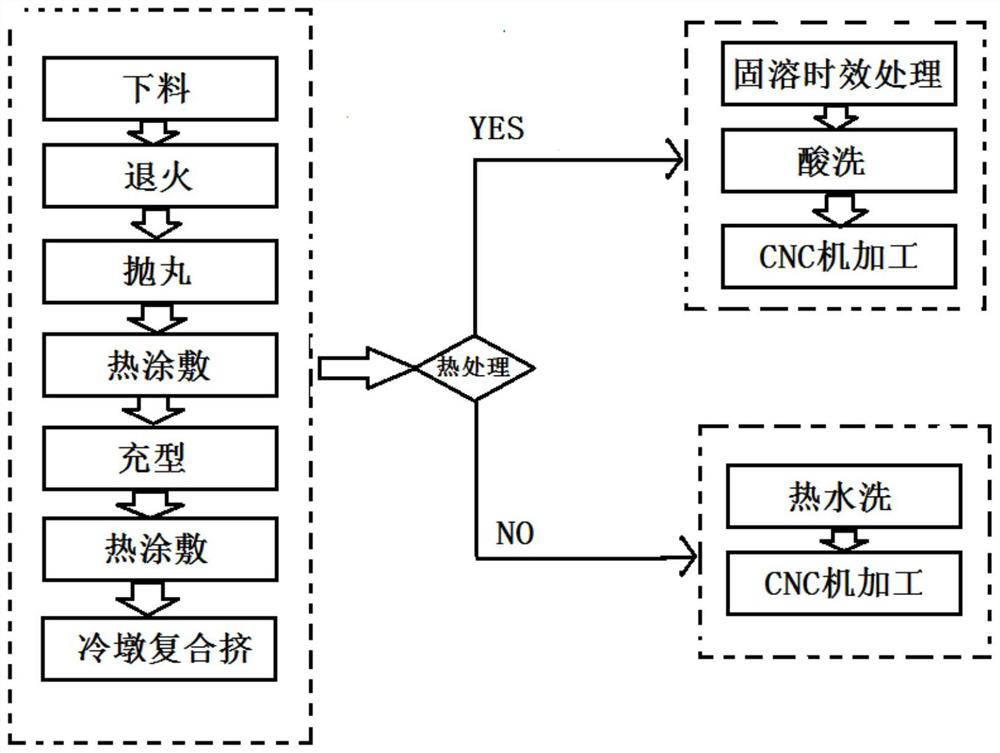

[0054] A cold heading and extrusion composite forming method for non-ferrous metal shell parts for vehicles, the specific steps are as follows figure 2 Shown:

[0055] (1) Using a circular saw machine to cut the non-ferrous metal AA6061 (series 6 aluminum alloy) to produce a non-ferrous metal shell part blank for vehicles with a burr of less than 0.5 mm;

[0056] (2) Carry out annealing treatment to the billet, the annealing temperature is controlled at 500 ° C for 4 hours, and it is directly out of the furnace;

[0057] (3) Use a pellet with a diameter of 0.35 mm to blast the annealed billet for 15 minutes;

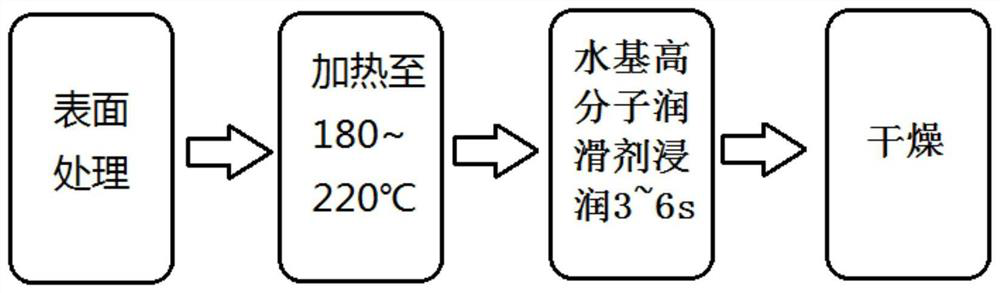

[0058] (4) Adopt water-based polymer lubricant III to carry out thermal coating treatment on the surface of the billet after shot blasting treatment, such as figure 1 Shown: After heating the billet to 180°C, soak it with water-based polymer lubricant I for 4 seconds. After treatment, the thickness of water-based polymer lubricant I on the surface of the billet is 4 μ...

Embodiment 2

[0076] A cold heading extrusion composite forming method for non-ferrous metal shell parts for vehicles, the specific steps are as follows:

[0077] (1) AA6082 (series 6 aluminum alloy) is blanked with a circular saw machine to produce a non-ferrous metal shell part blank for vehicles with a burr of less than 0.5 mm;

[0078] (2) Carry out annealing treatment to the billet, the annealing temperature is controlled at 520 ℃ for 4.5 hours, and it is directly out of the furnace;

[0079] (3) Use a pellet with a diameter of 0.35 mm to blast the annealed billet for 15 minutes;

[0080] (4) Use water-based polymer lubricant I to thermally coat the surface of the billet after shot blasting treatment, that is, heat the billet to 220 ° C and use water-based polymer lubricant I to infiltrate for 4 seconds. The thickness of Molecular Lubricant I is 5 μm, and then the blank is dried naturally;

[0081](5) Put the blank processed in step (4) into the filling die, and the filling punch mov...

Embodiment 3

[0088] A cold heading extrusion composite forming method for non-ferrous metal shell parts for vehicles, the specific steps are as follows:

[0089] (1) H62 brass is blanked by a circular saw machine to produce a non-ferrous metal shell part blank for vehicles with a burr of less than 0.5 mm;

[0090] (2) Carry out annealing treatment on the blank, the annealing temperature is controlled at 260-300°C for 2-4 hours, and it is directly out of the furnace;

[0091] (3) Use a pellet with a diameter of 0.35 mm to blast the annealed billet for 15 minutes;

[0092] (4) Use water-based polymer lubricant I to thermally coat the surface of the billet after shot blasting treatment, that is, heat the billet to 180°C and use water-based polymer lubricant I to infiltrate for 4s. The thickness of Molecular Lubricant I is 3 μm, and then the blank is dehydrated and dried for 8 minutes;

[0093] (5) Put the blank processed in step (4) into the filling die, and the filling punch moves down. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com