The method for synthesizing im-5 molecular sieve

A technology of IM-5 and molecular sieve, which is applied in the direction of molecular sieves and base exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of ineffective consumption, waste, and incompleteness of reaction raw materials, so as to overcome the incomplete reaction of raw materials and avoid Waste and ineffective consumption, avoiding the effect of time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Under stirring conditions, mix 35g of 1-methylpyrrolidine and 37mL of absolute ethanol, then add 43.97g of 1,5-dibromopentane dropwise to the above mixture at a rate of 3 drops / second, and pre- After reacting for 8 hours, the pre-reaction product A1 was obtained. The molar ratio of 1,5-dibromopentane, 1-methylpyrrolidine and solvent ethanol was 1:2.15:3.39.

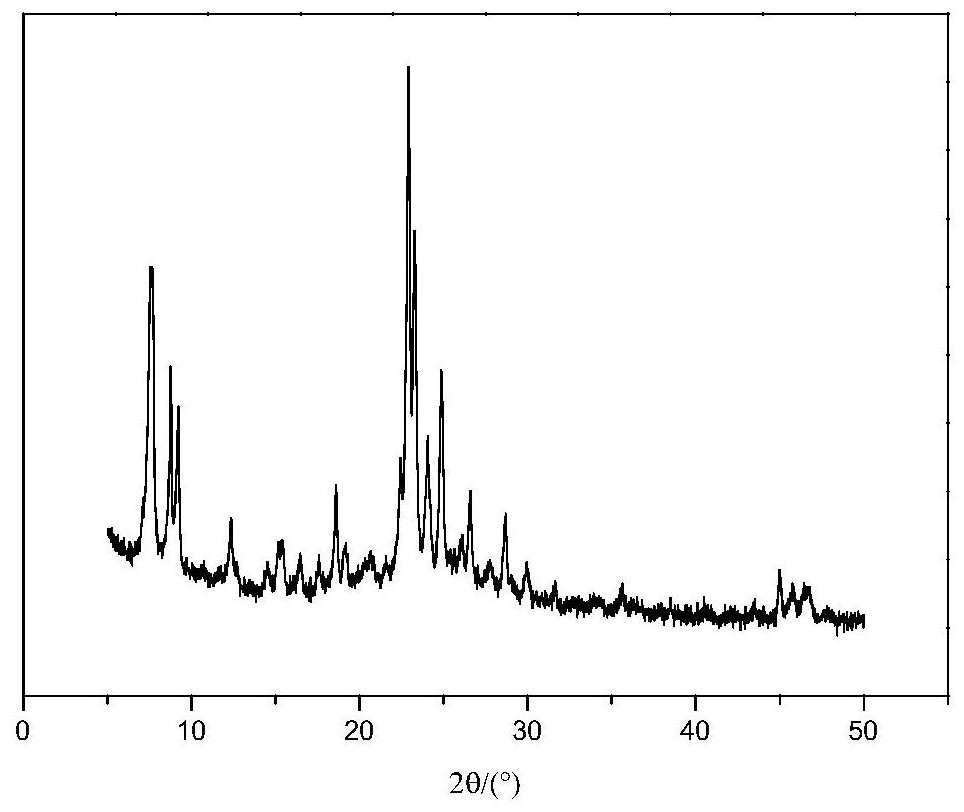

[0065] The pre-reaction product A1, 43.78gNaAlO 2 solution, 53.46mL of 30% by weight NaOH solution was dissolved in an appropriate amount of deionized water, mixed evenly, and under stirring conditions, 150g of solid silica gel was slowly added to make a milky white colloidal mixture to be crystallized, the molar composition of which was SiO 2 :Al 2 o 3 : Na 2 O:A1:H 2 O=100:2.5:17.5:8:900, continue to stir for 1h, transfer to a 1L autoclave with mechanical stirring, carry out the first stage of hydrothermal crystallization at 140°C for 2 days, then raise the temperature to 172°C for the second stage The secon...

Embodiment 2

[0068] Synthesize IM-5 molecular sieve according to the method of Example 1, the difference is that, under stirring conditions, 33.22g of 1-methylpyrrolidine and 48mL of ether are mixed, and then 43.97g of 1,5-dibromopentane is mixed with 10 drops / second Add it dropwise to the above mixed solution at a high speed, and pre-react at 35°C for 16 hours to obtain the pre-reaction product A2. The molar ratio of 1,5-dibromopentane, 1-methylpyrrolidine and solvent ether is 1:2.04:2.47 . The molecular sieve raw powder B2 was obtained by replacing A1 with the pre-reaction product A2. Its XRD spectrum was consistent with that of Example 1. The relative crystallinity and synthesis cost were calculated and listed in Table 1.

Embodiment 3

[0070]Synthesize IM-5 molecular sieves according to the method of Example 1, the difference is that, under stirring conditions, 34.19g of 1-methylpyrrolidine was mixed with 40mL of deionized water, and then 43.97g of 1,5-dibromopentane was mixed with 5 drops / Add it dropwise to the above mixture at a speed of 1 second, and pre-react at 60°C for 48 hours to obtain the pre-reaction product A3. The molar ratio of 1,5-dibromopentane, 1-methylpyrrolidine and solvent water is 1:2.1 : 11.8. The molecular sieve raw powder B3 was obtained by replacing A1 with the pre-reaction product A3. Its XRD spectrum was consistent with that of Example 1. The relative crystallinity and synthesis cost were calculated and listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com