Water-based integrated ceiling finish paint compounded from various emulsions and preparing method thereof

An integrated ceiling and emulsion technology, applied in the field of coatings, can solve the problems of failing to meet performance requirements, insufficient flexibility, solvent resistance and boiling water resistance, solvent resistance and boiling water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

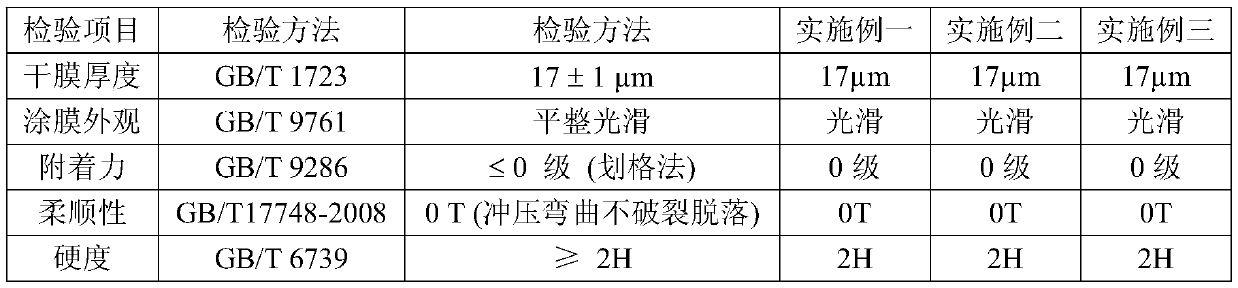

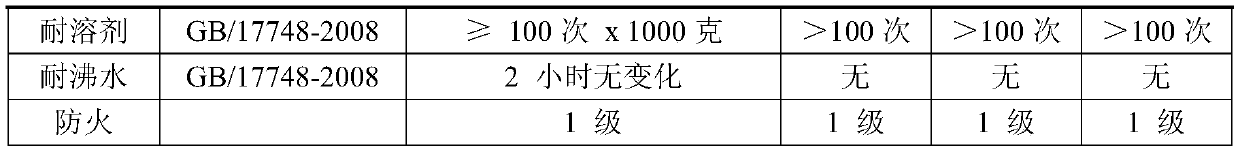

Embodiment 1

[0029] Weigh 43 parts of hydroxyl acrylic emulsion, 5.5 parts of silicon acrylic emulsion, 26 parts of titanium white paste, 5.5 parts of water-based polyurethane dispersion, 0.3 parts of defoamer, 0.25 parts of pH regulator, 4 parts Water-based amino resin, 0.8 part of thickener, 0.07 part of leveling agent and 14.58 parts of water, the titanium white slurry includes water, 0.25 part of preservative, 0.03 part of defoamer in a weight ratio of 25.5 parts , 0.3 parts of wetting agent, 3 parts of dispersant and 72 parts of titanium dioxide.

[0030] The hydroxy acrylic emulsion is 3094 Dow's hydroxy acrylic emulsion, the silicon acrylic emulsion is 996AD Shanghai Bard rich silicon acrylic emulsion, the water-based polyurethane dispersion is 72.3 million Wanhua chemical water-based polyurethane emulsion, and the pH regulator is AMP -95 pottery PH regulator, the water-based amino resin is 303 Chongqing Jianfeng Haokang chemical water-based amino resin, the thickener is ASE-60 pott...

Embodiment 2

[0035] Weigh 45 parts of hydroxy acrylic emulsion, 6 parts of silicon acrylic emulsion, 26 parts of titanium white slurry, 6 parts of water-based polyurethane dispersion, 0.3 parts of defoamer, 0.25 parts of pH regulator, 4.3 parts Water-based amino resin, 0.8 part of thickener, 0.07 part of leveling agent and 11.28 parts of water, the titanium white slurry includes 25.5 parts of water, 0.25 part of preservative, 0.03 part of defoamer , 0.3 parts of wetting agent, 3 parts of dispersant and 72 parts of titanium dioxide. Others are the same as embodiment one.

Embodiment 3

[0037] Weigh 47 parts of hydroxy acrylic emulsion, 5 parts of silicon acrylic emulsion, 26 parts of titanium white slurry, 6.5 parts of water-based polyurethane dispersion, 0.3 parts of defoamer, 0.25 parts of pH regulator, 3.8 parts Water-based amino resin, 0.8 part of thickener, 0.07 part of leveling agent and 10.28 parts of water, the titanium white slurry includes 25.5 parts of water, 0.25 part of preservative, 0.03 part of defoamer , 0.3 parts of wetting agent, 3 parts of dispersant and 72 parts of titanium dioxide. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com