Environment-friendly acidizing working solution suitable for low-permeability carbonate reservoir and preparation method thereof

A carbonate rock reservoir, environment-friendly technology, applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problems of increasing engineering costs, corrosion of the end face of the well wall, corrosion of the well pipe, etc., to reduce the acidity Loss, Corrosion Reduction, Effect of Extending Response Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

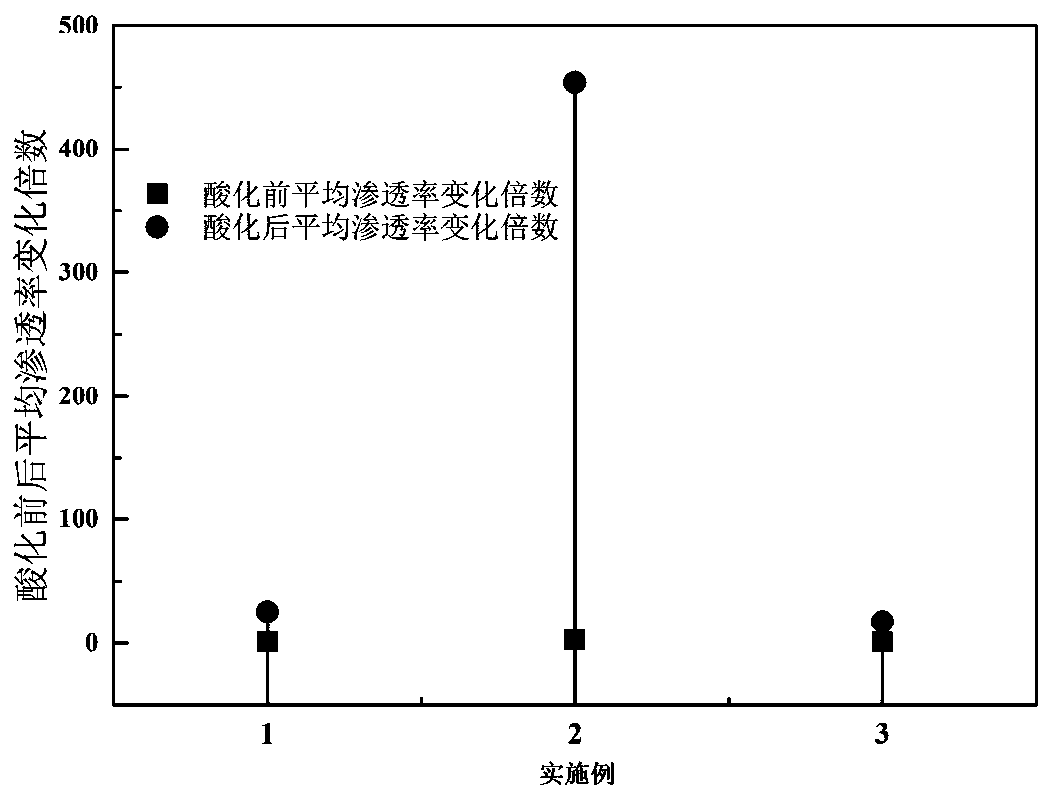

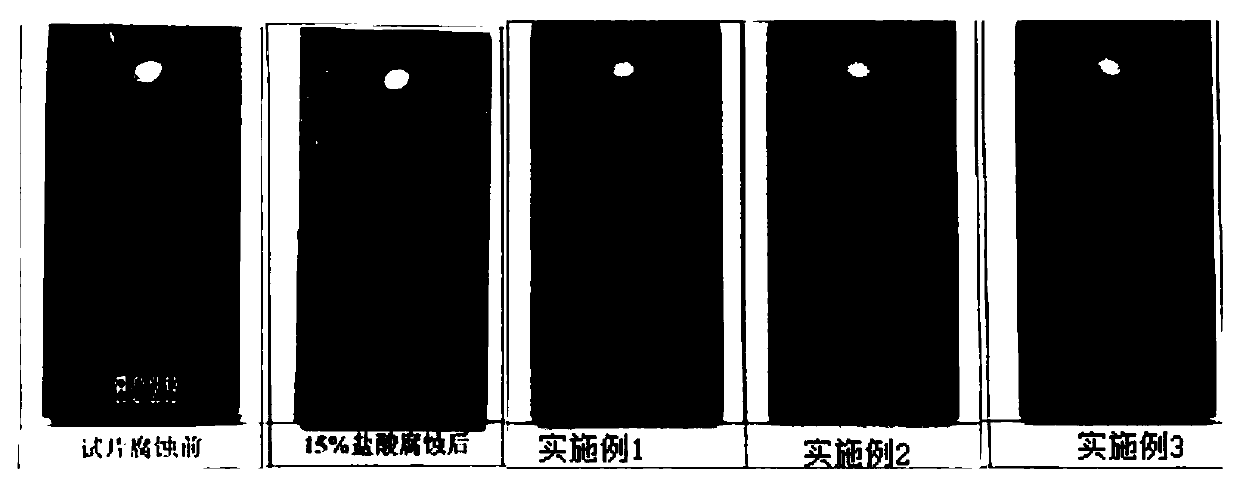

Embodiment 1

[0027] Add 1.5g of potassium chloride and 2g of ammonium chloride into 100mL of water, stir and dissolve fully to obtain a preposition; add 4g of glutamic acid N,N-diacetic acid, 3.5g of methylglycine diacetic acid, 4.5g of methanesulfonic acid and 6g of acetic acid were used to obtain an environment-friendly acidified working solution.

[0028] In Example 1, every 1 g is one serving.

Embodiment 2

[0030] Add 2g of potassium chloride and 2.5g of ammonium chloride into 100mL of water, stir and dissolve fully to obtain a preposition; add 4.5g of glutamic acid N,N-diacetic acid, 4g of methylglycine diacetic acid, 4g methanesulfonic acid and 8.5g acetic acid to obtain an environment-friendly acidified working solution.

[0031] In Example 2, every 1 g is one serving.

Embodiment 3

[0033] Add 2g of potassium chloride and 2g of ammonium chloride to 100mL of water, stir and dissolve fully to obtain a preposition; add 4.5g of glutamic acid N,N-diacetic acid, 4.5g of methylglycine diacetic acid, 3.5g of methanesulfonic acid and 5.5g of acetic acid to obtain an environment-friendly acidified working solution.

[0034] In Example 3, every 1 g is one serving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com