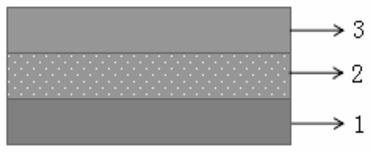

Method for preparing Y+Y2O3/Y2O3 composite coating through atmospheric plasma spraying technology

A composite coating, plasma technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problems of lateral cracks in the outer layer of the coating, high cost, quality needs to be further improved, etc., to achieve high deposition efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this example, the IC equipment plasma etching chamber protective coating is prepared on the 6061 alloy substrate, that is, the atmospheric plasma spraying technology is in Y+Y 2 o 3 The specific steps of coating preparation method are as follows:

[0029] (1) Weigh 20g of pure Y powder and 160g of Y 2 o 3 Powder, dry for subsequent use after mixing; Weigh 100g high-purity (purity 99.99wt%) Y 2 o 3 powder, dry for later use.

[0030] (2) Pretreat the surface of the sprayed substrate, which specifically includes the following steps: use acetone and alcohol to pretreat the surface of the sprayed substrate respectively, and sandblasting. The sandblasting medium used is white corundum, and the particle size range is 50 ~ 100 μm. With the micron grade Y+Y prepared in step (1) 2 o 3 Mixed powder, prepared Y+Y on 6061 alloy substrate by atmospheric plasma spraying technology 2 o 3 Composite coating, about 80 μm thick.

[0031] Among them, the atmospheric plasma sp...

Embodiment 2

[0037] In this example, the IC equipment plasma etching chamber protective coating is prepared on the 6061 alloy substrate, that is, the atmospheric plasma spraying technology is in Y+Y 2 o 3 The specific steps of coating preparation method are as follows:

[0038] (1) Weigh 30g of pure Y powder and 120g of Y 2 o 3 Powder, mixed and dried for later use. Weigh 50g high-purity (purity 99.99wt%) Y 2 o 3 powder, dry for later use.

[0039] (2) Pretreat the surface of the sprayed substrate, which specifically includes the following steps: use acetone and alcohol to pretreat the surface of the sprayed substrate respectively, and sandblasting. The sandblasting medium used is white corundum, and the particle size range is 50 ~ 100 μm. With the micron grade Y+Y prepared in step (1) 2 o 3 Mixed powder, prepared Y+Y on 6061 alloy substrate by atmospheric plasma spraying technology 2 o 3 Composite coating, about 100 μm thick.

[0040] Among them, the atmospheric plasma sprayin...

Embodiment 3

[0046] In this example, the IC equipment plasma etching chamber protective coating is prepared on the 6061 alloy substrate, that is, the atmospheric plasma spraying technology is in Y+Y 2 o 3 The specific steps of coating preparation method are as follows:

[0047] (1) Weigh 20g of pure Y powder and 160g of Y 2 o 3 Powder, dry for subsequent use after mixing; Weigh 60g high-purity (purity 99.99wt%) Y 2 o 3 powder, dry for later use.

[0048] (2) Pretreat the surface of the sprayed substrate, which specifically includes the following steps: use acetone and alcohol to pretreat the surface of the sprayed substrate respectively, and sandblasting. The sandblasting medium used is white corundum, and the particle size range is 50 ~ 100 μm. With the micron grade Y+Y prepared in step (1) 2 o 3 Mixed powder, prepared Y+Y on 6061 alloy substrate by atmospheric plasma spraying technology 2 o 3 Composite coating, about 80 μm thick.

[0049] Among them, the atmospheric plasma spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com