Controllable preparation device and method for large-area thin film

A large-area film and preparation device technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of low effective gas conversion rate, energy waste, loss, etc., to save energy and production costs , Improve the gas conversion rate and reduce the growth temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

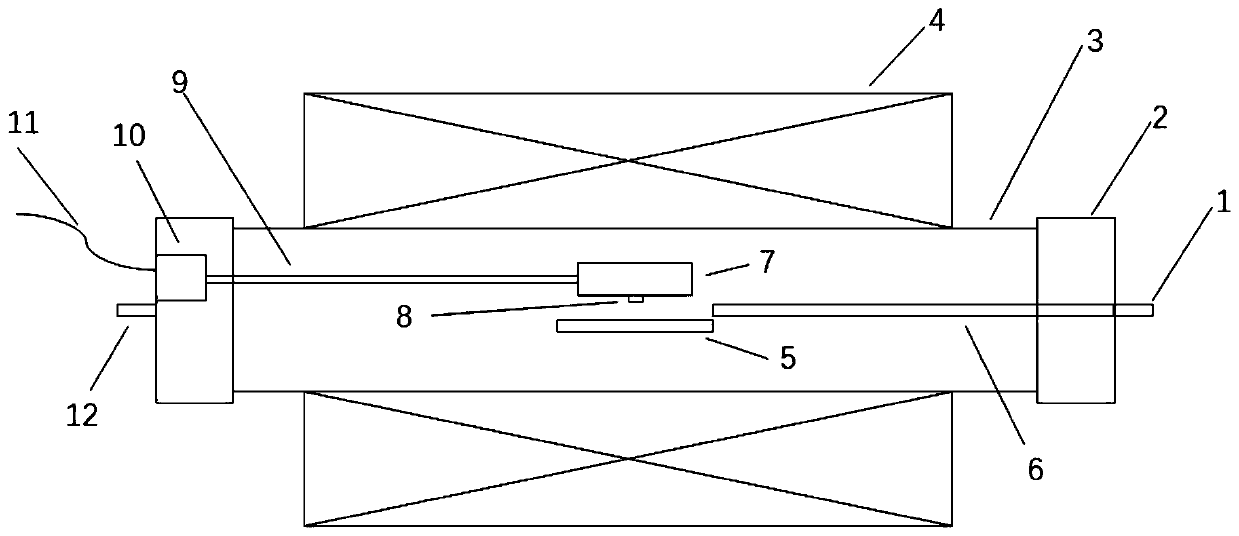

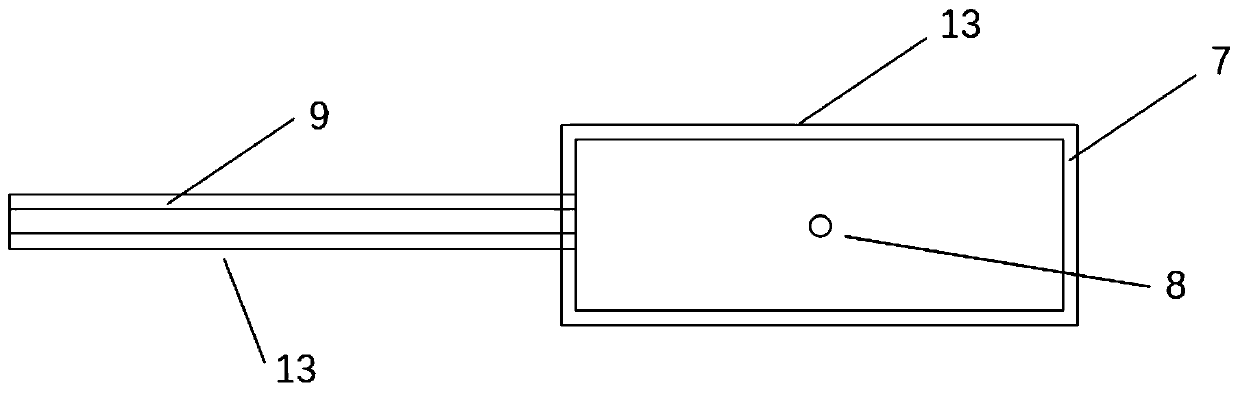

[0024] This embodiment provides an efficient and controllable device and method for preparing large-area thin films. The schematic diagram of the device is shown in figure 1 , figure 2 As shown; specifically includes: intake pipe 1, flange 2, quartz tube 3, heating device 4, sample stage 5, gas conduit 6, ultraviolet generating device 7, ultraviolet emitting probe 8, control arm 9, motor device 10, external wire 11. Air outlet 12, heat insulation layer 13; wherein,

[0025] One end of the quartz tube 3 is fixed and sealed, and an air outlet 12 is provided;

[0026] The heating device 4 is coated on the side wall of the quartz tube 3 and used for heating the growth substrate;

[0027] The sample stage 5 is fixed in the quartz tube 3 and is located in the center for placing the growth substrate;

[0028] The ultraviolet emitting device 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com