A wind tunnel fair-faced concrete construction technology

A technology of fair-faced concrete and construction technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of low concrete pouring accuracy and achieve The effect of perfect reinforcement measures, improved construction accuracy and high degree of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

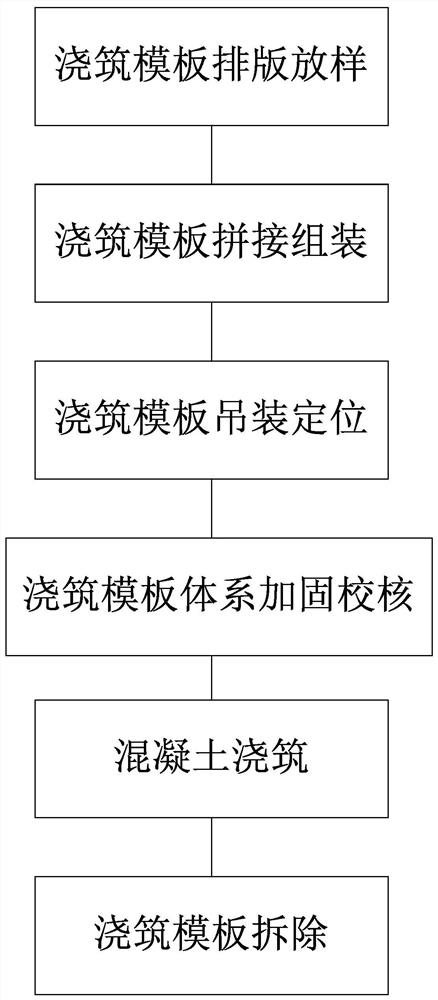

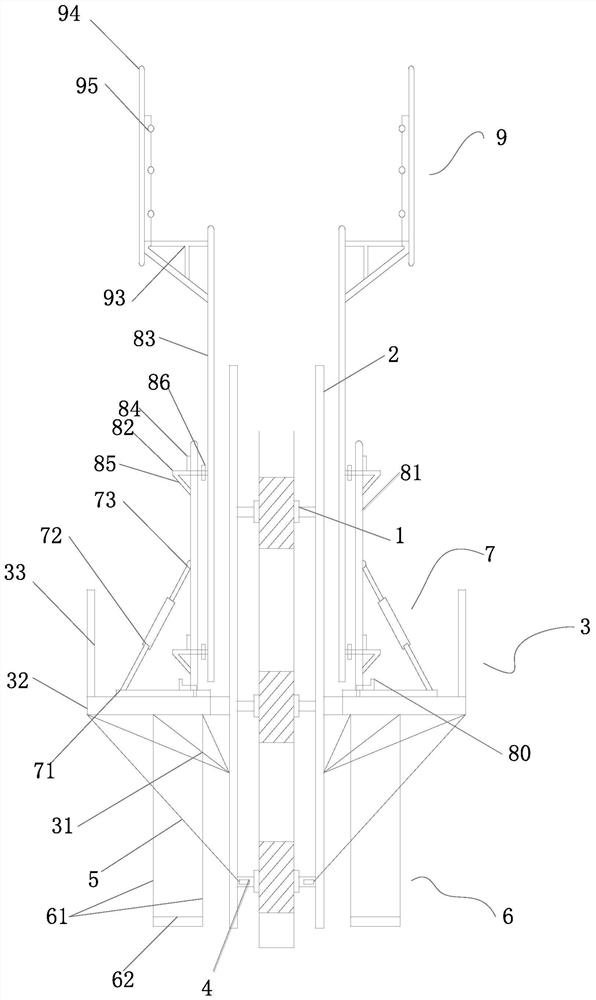

[0046] Such as figure 1 Shown, a kind of wind tunnel fair-faced concrete construction technology disclosed by the invention comprises the following steps:

[0047] (S1) Typesetting and lofting of pouring formwork: Carry out surveying and mapping modeling of the construction pouring area, adopt high-precision BIM modeling and layout technology, accurately control the position and installation of each formwork, ensure that the accuracy is controlled within 1mm, and determine the size and style of the pouring formwork .

[0048] (S2) Splicing and assembly of pouring formwork: Assemble the wind tunnel casting mold according to the results of surveying and mapping modeling. First, cut the formwork with high precision based on the determined size and style of the pouring formwork; then perform steel frame welding and flatness according to the cut formwork Adjust to form a hole-shaped pouring formwork steel frame; finally, splice the cut formwork and steel frame and adjust the flatn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com