Multi-gear static zoom lens based on super-surface material

A zoom lens and metasurface technology, applied in the field of micro-nano optical zoom lens, can solve the problems of complex optical design, large volume and weight of zoom lens, difficult system design and manufacturing, etc. The effect of simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

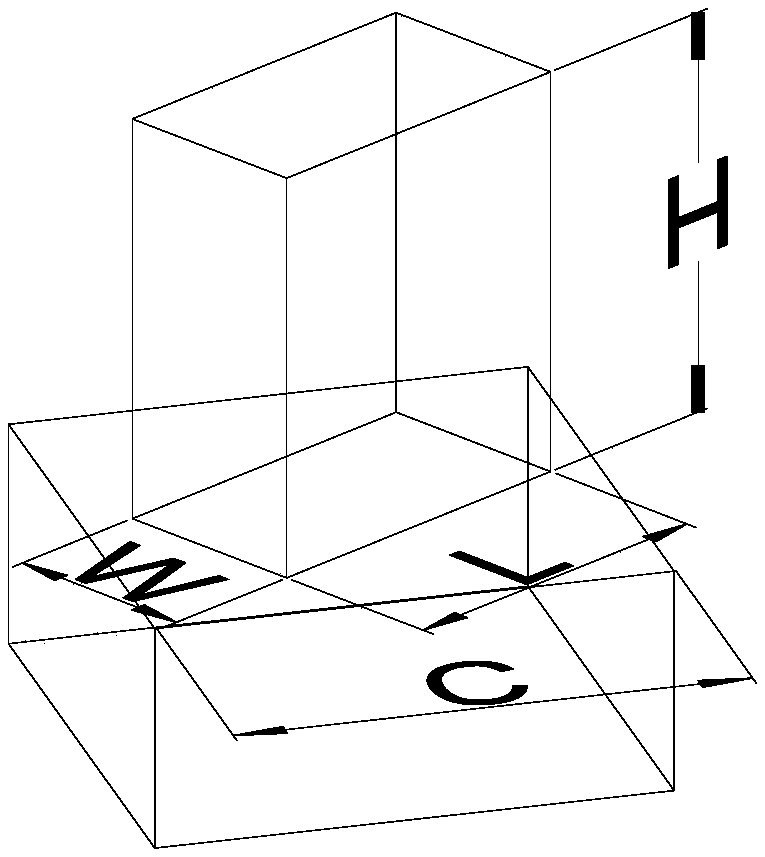

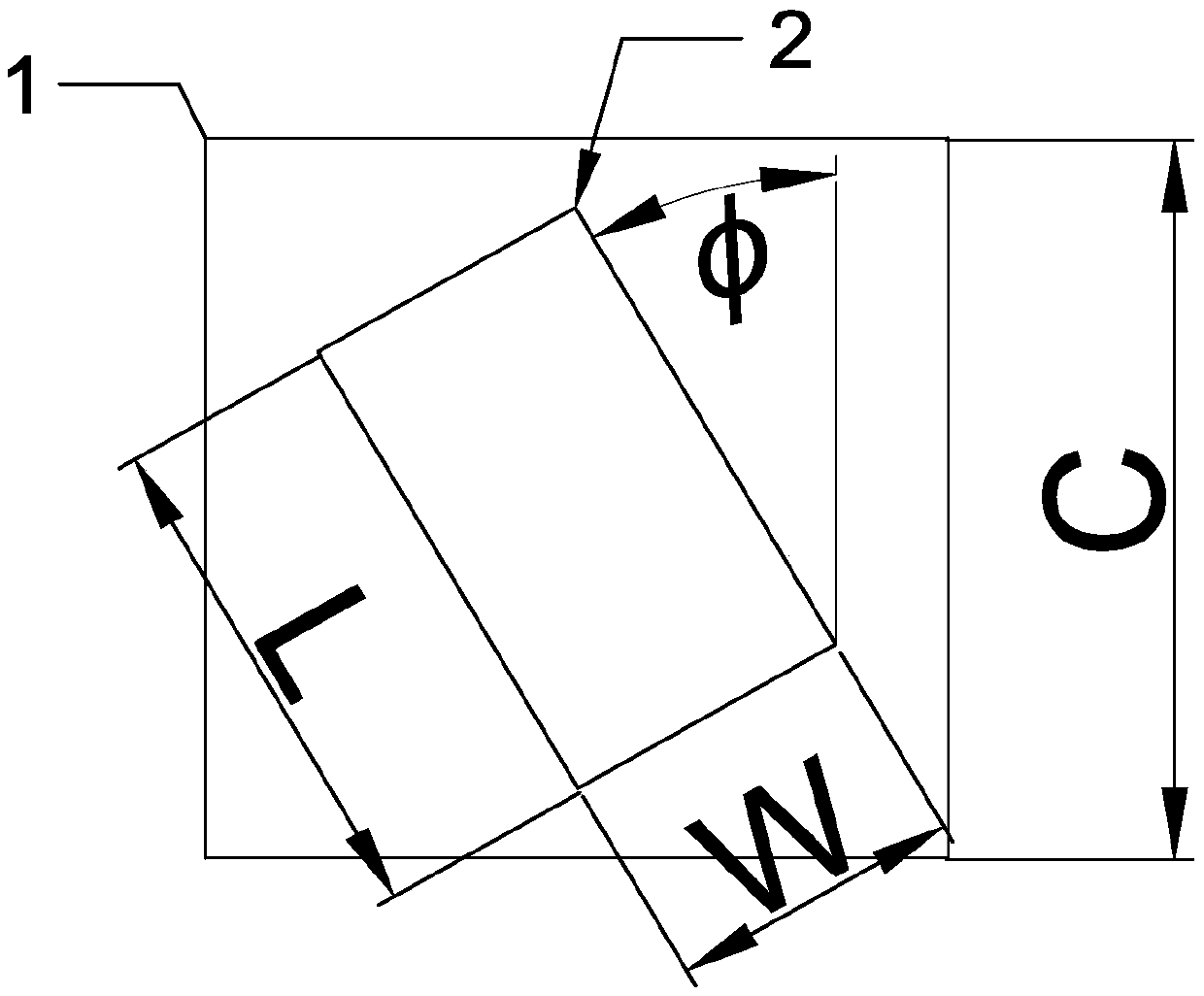

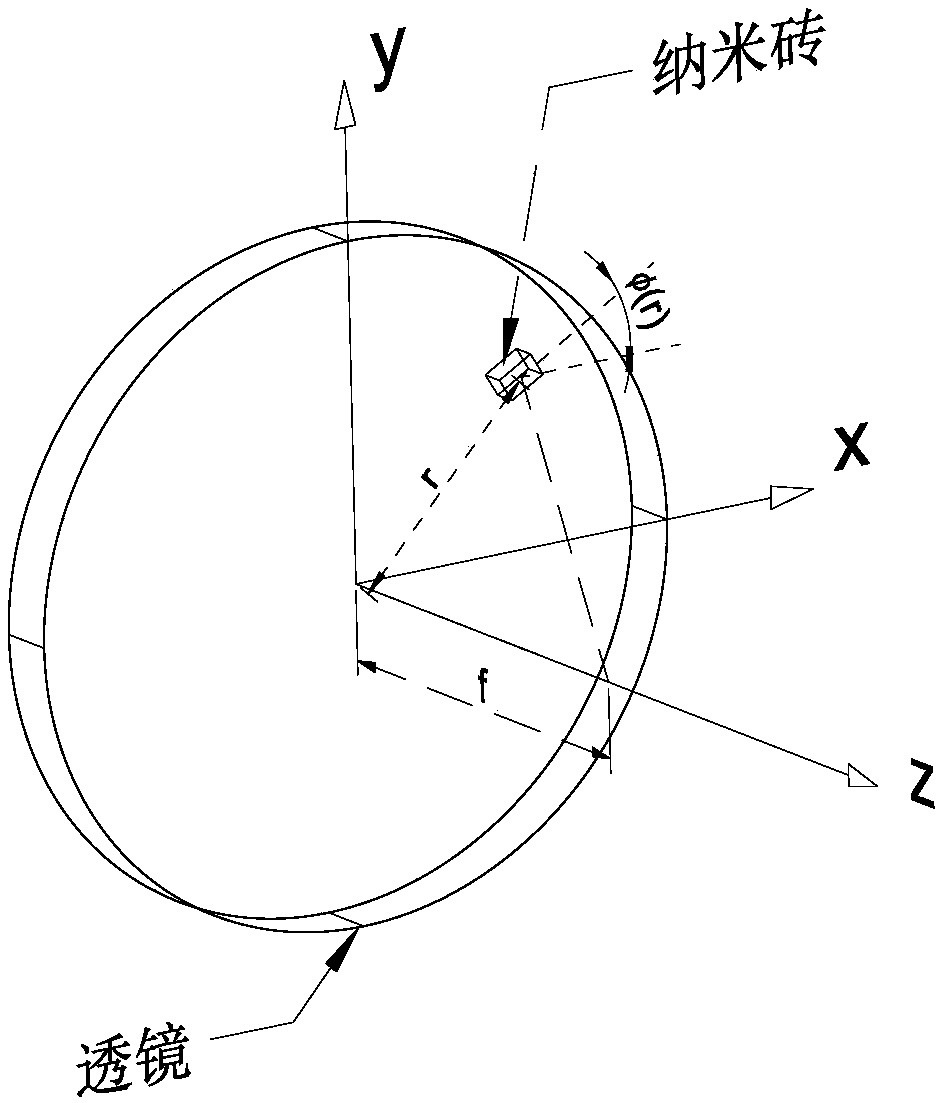

[0025] In the embodiment of the present invention, in order to achieve the same phase modulation function as the traditional lens, first, take a single nano-brick structure as an example, such as figure 2 , the metasurface material is composed of the underlying transparent substrate and nano-bricks, the xoy coordinate system is established with the center of the nano-brick as the origin, the long side of the nano-brick is taken as the long axis, the short side is taken as the short axis, and the angle between the long axis and the x-axis is taken as The steering angle φ of the nanobrick, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com