Beam combiner packaging structure of high-power laser system

A laser system and packaging structure technology, applied in the direction of laser devices, laser cooling devices, lasers, etc., can solve the problems of poor long-term stability, poor heat dissipation effect of beam combiner packaging, etc., achieve easy operation, reasonable packaging structure design, and improve heat dissipation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

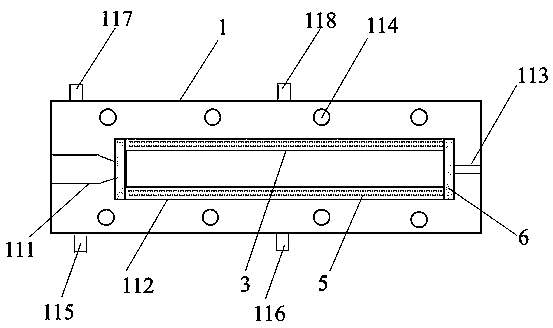

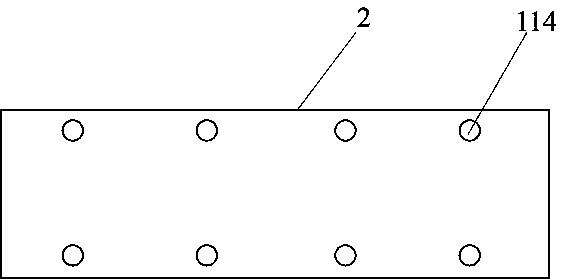

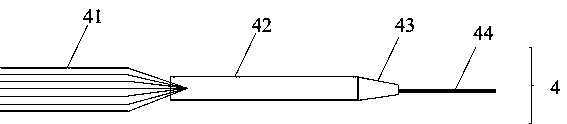

[0048] A beam combiner package structure of a high-power laser system, comprising a fiber beam combiner, a metal aluminum package base plate, a metal aluminum package cover plate and a quartz package sleeve, the base plate is provided with such Figure 4 The shown input fiber groove, rectangular groove and output fiber groove composed of several separated small grooves; the fiber combiner includes input fiber bundle, heat shrinkable tube, fiber bundle taper and output fiber; input fiber Each bare optical fiber of the bundle is put into the small groove of the input fiber groove respectively, and then penetrates into the heat-shrinkable tube together. The optical fiber is placed in the output optical fiber groove; the two ends of the packaging sleeve are respectively fixed with the metal box body with heat-conducting sealant, and the gap between the packaging sleeve and the rectangular groove is filled with heat-conducting materials; the side of the metal base plate contains two...

Embodiment 2

[0052] The package structure of a beam combiner for a high-power laser system provided in Example 2 is different from that in Example 2 in that the heat-conducting sealant is cured glue modified by hydroxyl-terminated polyborosiloxane, and the The heat-conducting material is a kind of insulating and heat-conducting silicone grease, which is composed of: 10wt% hydroxyl silicone oil, 0.6wt% silane coupling agent, 4wt% hydroxyl-terminated polyborosiloxane, and the rest is nitride ceramic powder; the silane coupling agent coated on the surface of nitride ceramic powder, and then mixed with hydroxyl silicone oil; the heat-shrinkable tube is prepared by the following steps:

[0053] a: Seal both ends of the quartz capillary with sealant;

[0054] b: After the glue is dry, wrap a layer of paraffin wax outside the sealant, so that the acid solution will not corrode the sealant and enter the inside of the capillary; tie a PTFE string that will not be corroded at one end of the capillar...

Embodiment 3

[0060] Compared with Embodiment 1, Embodiment 3 differs in that the metal box is made of red copper, and the others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com