Submarine cable wiring design method for offshore wind power

A submarine cable and wiring design technology, applied in the direction of cable laying equipment, etc., can solve the problems of cable wiring increasing maintenance and repair costs of offshore wind farms, development restrictions, cost waste, etc., to reduce maintenance costs and repair costs, and reduce construction Cost, the effect of reducing wiring costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

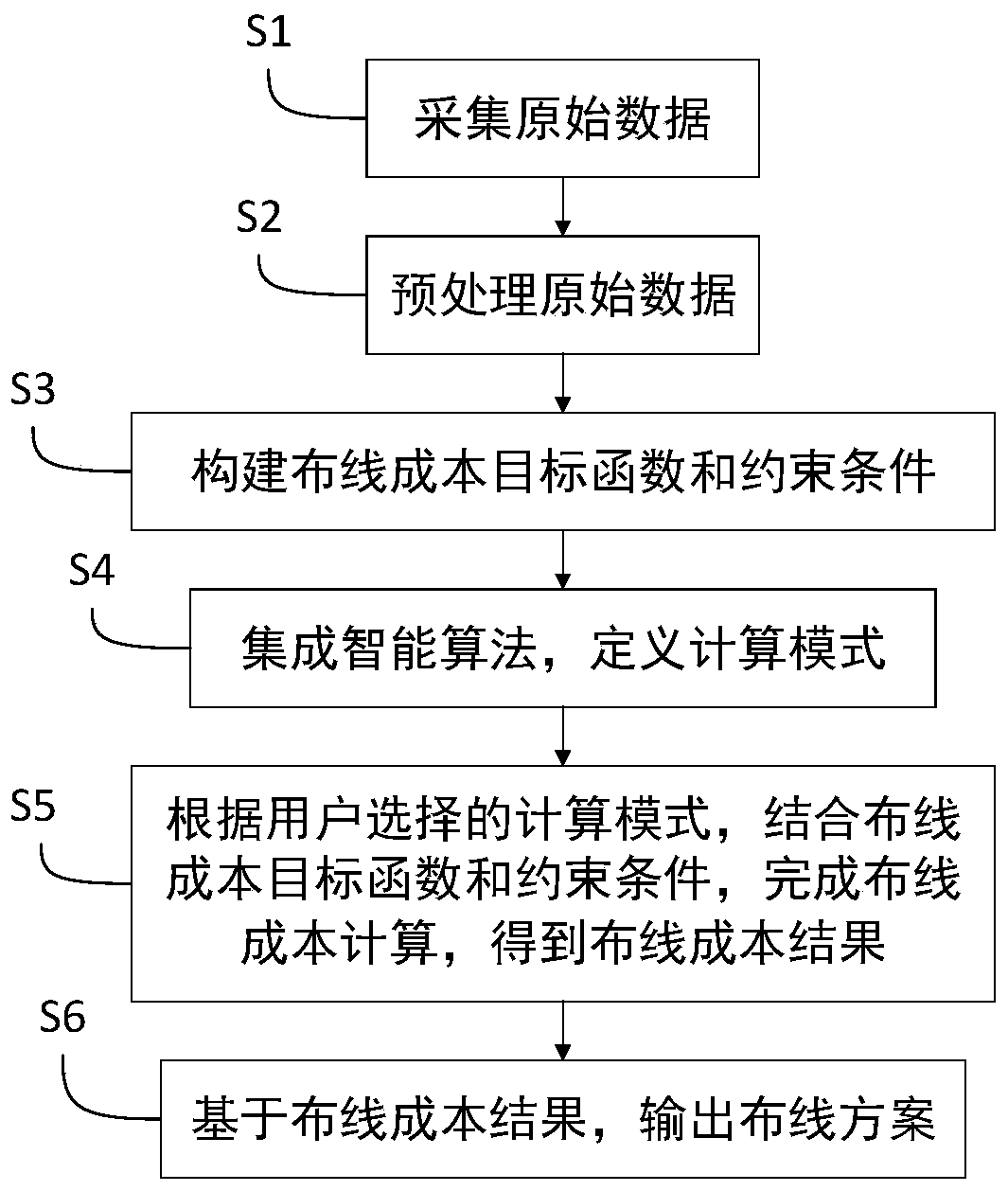

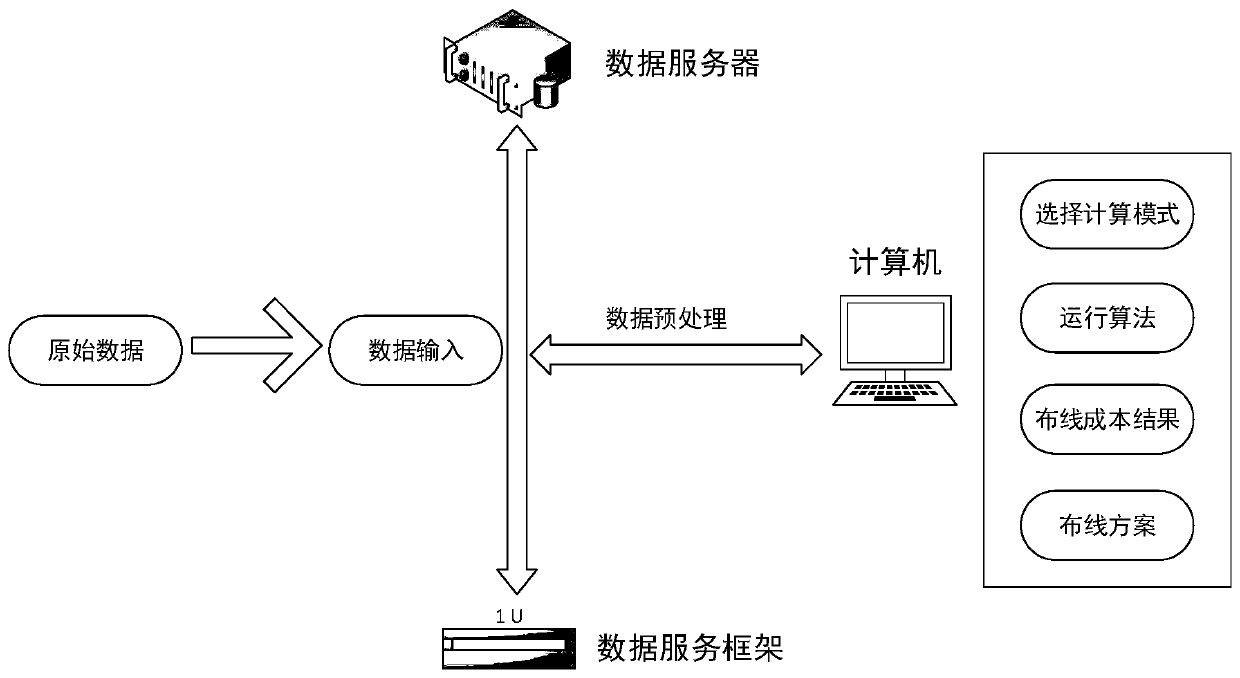

[0043] Such as figure 1 As shown, a submarine cable layout design method for offshore wind power includes the following steps:

[0044] S1. Collect raw data, where the raw data includes distance d, cable cost c, transportation cost t and landfill cost f, and distance d includes distance d between fans 1 , the distance between the fan and the transformer station d 2 , the distance between the transformer station and the load point d 3 ;

[0045] S2. Preprocessing raw data:

[0046] S21, removing the unique attribute of the original data;

[0047] S22. Perform interpolation processing on missing values of the original data;

[0048] S23. Encoding the attributes corresponding to the original data;

[0049] S24. Standardize and regularize the original data;

[0050] S25. Selecting features corresponding to the original data;

[0051] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com